+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Uniaxial geogrids play a crucial role in modern civil engineering, particularly in soil reinforcement and construction. These innovative materials are designed to provide structural support and stability in a variety of construction scenarios, from road construction to slope stabilization. In this article, we will explore what uniaxial geogrids are, their purpose, and how they differ from their biaxial counterparts. Understanding the distinction between these two types of geogrids is essential for selecting the right material for specific engineering applications.

What is an Uniaxial Geogrid?

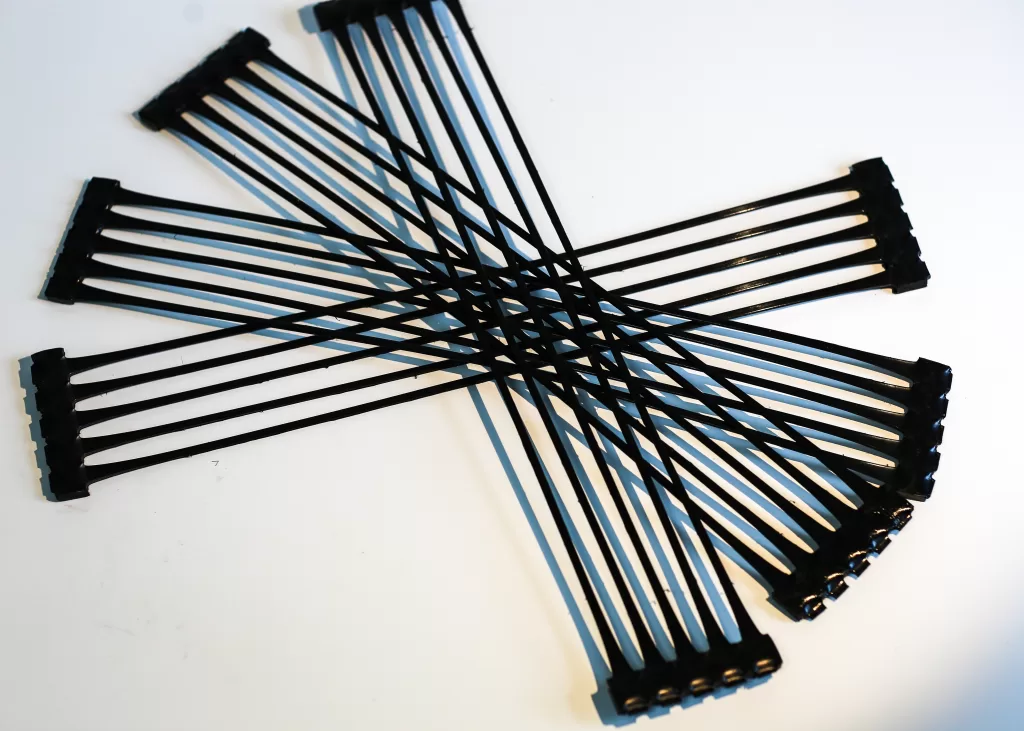

A uniaxial geogrid is a type of geosynthetic material specifically designed to provide reinforcement in one direction. It is made from high-strength polymer materials like polyester, polypropylene, or polyethylene, and its primary function is to provide soil stabilization, improve load distribution, and prevent soil movement. The term “uniaxial” refers to the fact that the geogrid has high tensile strength in one direction (usually the machine direction) but less strength in the perpendicular direction.

Key Characteristics of Uniaxial Geogrids:

- Tensile Strength in One Direction: Uniaxial geogrids are engineered to have significant strength along one axis, which makes them ideal for applications where reinforcement is needed in a single direction, such as slope stabilization, reinforced soil walls, or road base reinforcement.

- Grid Structure: They consist of a grid-like structure with uniformly spaced ribs or apertures, designed to interlock with the surrounding soil, gravel, or other fill materials. The grid structure ensures the transfer of loads and improves the overall mechanical properties of the soil.

- Material Composition: Made from polymers (like polyester, polypropylene, or high-density polyethylene), uniaxial geogrids offer durability, resistance to environmental conditions, and a long lifespan in construction and civil engineering projects.

- Flexibility and Durability: The material is generally flexible, allowing it to conform to the surface or terrain it is installed in. This flexibility makes it suitable for uneven or sloped areas. Additionally, uniaxial geogrids have high resistance to UV degradation, chemicals, and extreme temperatures.

- Cost-Effective and Lightweight: Compared to other reinforcement techniques like steel reinforcements, uniaxial geogrids are relatively lightweight and easy to handle, making them a cost-effective choice for reinforcement.

Applications of Uniaxial Geogrids:

- Soil Reinforcement for Retaining Walls: Uniaxial geogrids are commonly used behind retaining walls or reinforced earth walls. They help distribute vertical and lateral loads and resist the movement of soil, preventing the wall from failing under pressure.

- Slope Stability: In areas prone to landslides or erosion, uniaxial geogrids can be used to reinforce slopes, providing additional strength to the soil and preventing the loss of material over time.

- Road Base and Pavement Construction: Uniaxial geogrids are used in road construction to stabilize the base layers, reduce rutting and deformation under traffic loads, and improve the overall performance of the road structure.

- Landfills and Waste Containment: They can be used in landfill projects to stabilize the foundation and prevent shifting, reducing the risk of landfill slope failures.

- Bridge Approaches and Embankments: In embankment construction, uniaxial geogrids provide reinforcement to support structures like bridges, helping maintain the integrity of the embankment and distribute the load evenly.

What is the Purpose of a Geogrid?

The purpose of a geogrid is to reinforce and stabilize soil or other materials in various civil engineering and construction applications. Geogrids are used to improve the load-bearing capacity of soil, prevent deformation, reduce settlement, and enhance the stability of structures like roads, retaining walls, slopes, and embankments. Made from high-strength materials such as polyester, polypropylene, or polyethylene, geogrids are designed with an open grid structure to allow interlocking with soil particles or aggregates, providing a durable and effective solution for soil reinforcement.

Soil Reinforcement and Stabilization

- Load Distribution: Geogrids help distribute applied loads over a larger area, reducing the intensity of pressure on the soil beneath. This is especially crucial for areas with weak or loose soils, such as soft or granular soils, which may otherwise be prone to settlement.

- Increased Load-Bearing Capacity: By providing a structural framework, geogrids enhance the soil’s ability to support heavier loads. This is critical in applications such as roads, railways, and heavy infrastructure where soil must bear significant weight over time.

Prevention of Soil Erosion and Settlement

- Preventing Erosion: In applications like slopes, embankments, and coastal protection, geogrids help prevent erosion by stabilizing the soil and keeping it intact. They prevent the soil from washing away due to water runoff, especially in areas subject to rainfall or flooding.

- Reducing Differential Settlement: Geogrids help mitigate uneven settling by distributing loads more evenly, preventing differential settlement where one part of the structure sinks more than others, which can lead to cracking, tilting, or failure.

Improving the Performance of Retaining Walls

- Reinforced Earth Walls: Geogrids are commonly used in the construction of reinforced earth walls. These walls rely on layers of geogrid placed behind the wall blocks or stone to provide strength and prevent wall failure due to lateral soil pressure. Geogrids are placed in the backfill behind the retaining wall to provide reinforcement over a larger area, thus distributing the lateral forces across the soil.

Slope Stabilization

- Slope Reinforcement: Geogrids are widely used to stabilize slopes and prevent landslides or soil slippage. When installed in layers within the soil, the geogrid improves the shear strength of the soil and keeps the slope intact under the pressure of gravity and external forces, such as rainfall or seismic activity.

- Preventing Soil Sliding: In projects involving steep slopes or unstable terrain, geogrids prevent soil from sliding downhill by adding tensile strength and interlocking the soil particles. This is especially useful in landscaping, road construction, or tunnel approaches.

Road and Pavement Construction

- Improving Road Stability: In road construction, geogrids are used to stabilize the subgrade and subbase layers, reducing rutting and cracking caused by heavy traffic loads. They also help distribute traffic loads more evenly across the road surface, increasing the durability of the pavement.

- Increasing Pavement Lifespan: By improving the structural integrity of the roadbase, geogrids extend the lifespan of roadways by reducing the need for frequent repairs or resurfacing.

Reinforced Foundations and Embankments

- Reinforcing Foundations: Geogrids are used in the construction of foundations, particularly in areas with weak or unstable soil. By improving the soil’s structural capacity, geogrids provide additional support for buildings, bridges, and other large structures.

- Embankment Stability: When used in embankments or raised roads, geogrids help prevent settlement and maintain the structural integrity of the embankment over time. The geogrids act as a reinforcing element, keeping the soil in place and preventing it from shifting or eroding under heavy loads.

Improved Drainage and Filtration

- Soil Filtration: Some geogrids are combined with geotextiles or other materials to act as filters that prevent fine soil particles from clogging the geogrid structure while still allowing water to flow through. This is particularly useful in retaining walls or drainage systems, where proper water flow is essential to prevent hydrostatic pressure from building up behind the structure.

Environmental Protection

- Sustainable Development: Geogrids are often used in environmentally sensitive areas for the construction of retaining walls, slope protection, or erosion control without disturbing the surrounding ecosystem. Their durability and ability to reduce the need for additional soil or material placement make them a sustainable solution.

The primary purpose of a geogrid is to reinforce and stabilize soil or fill materials, improving the strength, performance, and longevity of a wide range of construction projects. By preventing soil erosion, increasing load-bearing capacity, and reducing settlement, geogrids are crucial in the construction of roads, retaining walls, embankments, and slopes. Their versatility, cost-effectiveness, and long-term durability make them an essential material in modern civil engineering and geotechnical applications.

What is the Difference Between Uniaxial and Biaxial Geogrids?

The key difference between uniaxial and biaxial geogrids lies in their strength and reinforcement direction:

Uniaxial geogrids provide strength along a single axis, typically the length of the grid. This design makes them ideal for soil reinforcement in areas where forces are concentrated in one direction. Much like uniaxial crystals, which have a single optic axis, uniaxial geogrids stabilize soil along that one primary axis.

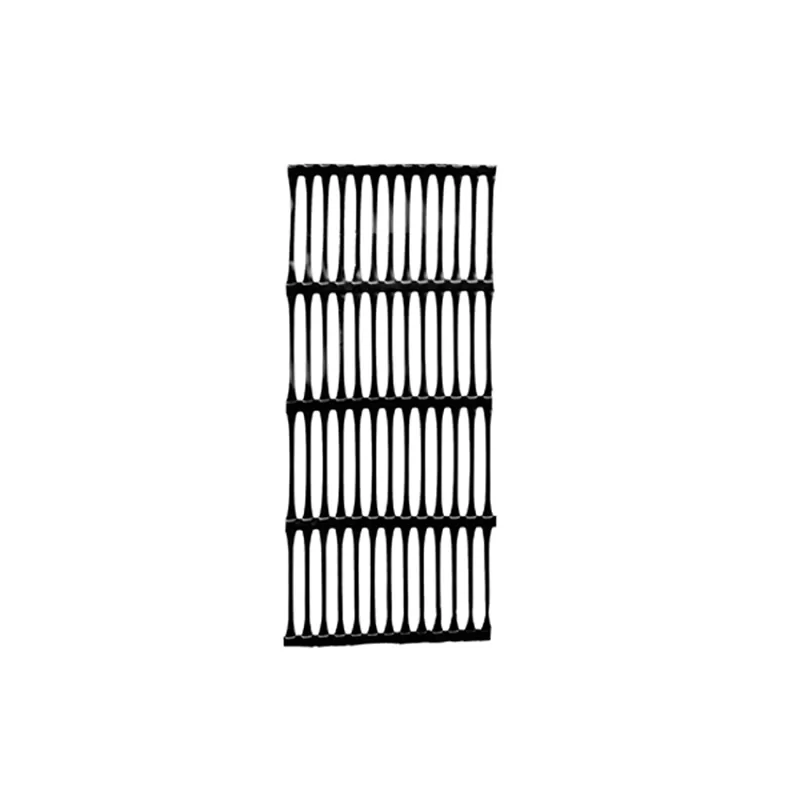

Biaxial geogrids, by contrast, offer strength in two perpendicular directions: both longitudinal and transverse. This multidirectional strength makes them particularly versatile, and suitable for scenarios where forces act in multiple directions, such as road foundations or embankment stabilization. Similar to biaxial crystals, which have two distinct optic axes that intersect at a common point (the biaxial point), biaxial geogrids provide reinforcement across two planes, making them adaptable to varying stress directions.

Both types of geogrids serve the same primary function of reinforcing soil, but the decision between uniaxial and biaxial depends on the specific soil conditions and expected load distribution in a given construction project.

What are the Practical Applications of Uniaxial and Biaxial Geogrids?

Biaxial geogrids, on the other hand, are designed to resist forces in both horizontal and vertical directions. This makes them ideal for situations where forces are applied from multiple directions, such as:

- Road Construction: Biaxial geogrids help distribute loads from traffic and prevent soil deformation, such as rutting and cracking, by evenly spreading forces over a larger area.

- Foundation Reinforcement: In foundation applications, they provide stability and prevent differential settlement by distributing loads evenly.

- Embankment Stabilization: They are used in embankments to stabilize soil and prevent shifting or deformation due to varying forces.

The primary benefit of biaxial geogrids is their ability to distribute loads evenly across multiple directions, preventing rutting, cracking, and other forms of soil degradation.

Key Differences and Considerations

- Directional Strength: Uniaxial geogrids excel in situations requiring strength in one direction, while biaxial geogrids are suited for applications with multidirectional forces.

- Application Context: Uniaxial geogrids are ideal for slope stabilization and areas with limited directional force, whereas biaxial geogrids are preferred in road construction, foundation, and embankment applications.

When selecting the appropriate type of geogrid, consider the direction of the forces acting on the soil, the specific engineering needs, and the desired stability outcomes. Understanding these differences is essential for choosing the right geogrid for each project.

In conclusion, uniaxial geogrids are an essential component of modern construction and soil stabilization techniques. They offer unparalleled strength in a single direction, making them ideal for projects where soil reinforcement is needed under concentrated directional loads. On the other hand, biaxial geogrids provide multidirectional strength and are better suited for applications requiring balanced reinforcement. By understanding the differences and applications of these two types of geogrids, engineers and construction professionals can select the right material to ensure structural stability and durability in their projects.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)