+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

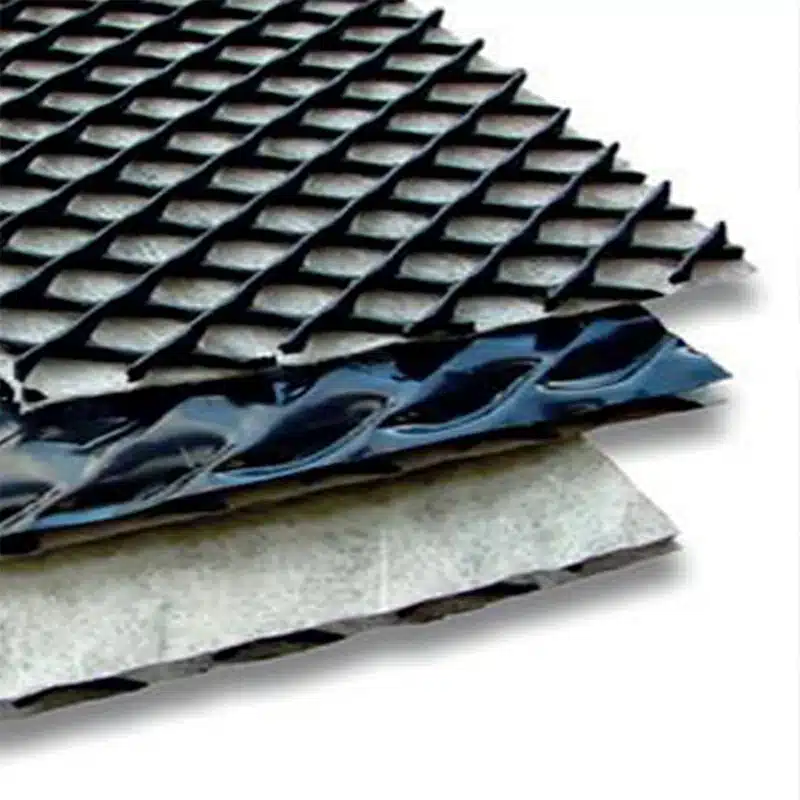

In the realm of civil engineering and construction, geosynthetics have emerged as pivotal materials, enhancing durability and sustainability in various projects. These synthetic products, used in geological and environmental applications, range from stabilization and filtration to drainage and barrier functions. Ensuring their quality and performance is crucial, which is where ASTM International standards come into play. This article delves into the ASTM standards specific to geosynthetics, shedding light on their significance and the tests designed to assess the quality and functionality of these innovative materials.

What are ASTM standards for geotextiles?

ASTM standards for geotextiles are technical specifications developed by the American Society for Testing and Materials (ASTM) to ensure quality, performance, and safety in geotextile applications. Geotextiles are permeable fabrics that, when used in association with soil, have the ability to separate, filter, reinforce, protect, or drain. These standards cover a wide range of properties and testing procedures specific to geotextiles, including:

- Mechanical Properties: This includes tensile strength, puncture resistance, tear resistance, and seam strength. Tests like ASTM D4632 for grab tensile strength and ASTM D6241 for puncture resistance are commonly used.

- Hydraulic Properties: Important for applications involving filtration and drainage. Tests include permeability (ASTM D4491) and water flow rate (ASTM D4491).

- Durability: Evaluate how geotextiles perform under exposure to various environmental conditions. Tests include ultraviolet (UV) degradation (ASTM D4355) and biological degradation resistance.

- Geomembrane Compatibility: ASTM standards also assess the compatibility of geotextiles with geomembranes, which is crucial for projects like landfills and reservoir liners.

- Quality Control and Installation Procedures: Standards also exist to guide the quality control processes during manufacturing and proper installation techniques to ensure the geotextiles function as intended.

These standards are vital for civil engineering projects, ensuring that the geotextiles used in construction projects like roads, embankments, and erosion control systems meet specific criteria for performance and safety.

What is the pull-out test for geosynthetics?

The pull-out test for geosynthetics is a method used to determine the interaction properties between geosynthetics, like geotextiles or geomembranes, and surrounding soil. This test is crucial for applications in geotechnical and civil engineering projects, such as retaining walls, embankments, and landfill covers, where the stability of the structure depends significantly on the anchorage strength of the geosynthetic material.

Here’s how the pull-out test typically works:

- Sample Preparation: A segment of the geosynthetic material is placed within a test box, and soil is compacted around it to simulate field conditions. The geosynthetic is left with a free end to which the pulling force will be applied.

- Application of Force: A force is gradually applied to the free end of the geosynthetic. This force tries to pull the geosynthetic out of the soil.

- Measurement: The resistance to pull-out (frictional resistance and/or mechanical interlock) offered by the soil against the pulling force is measured. The test records the maximum force at which either the geosynthetic starts to slip or when it reaches its tensile strength limit and breaks.

- Data Analysis: The data collected helps in determining the interaction characteristics such as friction coefficients and pull-out resistance, which are essential for designing safe and effective geotechnical solutions.

The results of a pull-out test are used to evaluate the suitability of specific geosynthetics for different soil types and conditions, ensuring that the chosen materials will perform adequately under expected field stresses.

What is the grab tensile test for geotextiles?

The grab tensile test for geotextiles is a standardized method used to measure the tensile strength of these materials, which are often used in construction and civil engineering projects. The purpose of this test is to determine the resistance of geotextiles to being pulled apart under tension, which is critical for applications where they are used to reinforce soil or stabilize terrain.

Procedure:

- Sample Preparation: A sample of the geotextile is cut to specified dimensions, typically with a width of a few inches.

- Testing: The sample is placed in a tensile testing machine. Grips or clamps on either end of the sample hold it securely. Only a central part of the width of the sample is subjected to the tensile force, hence the term “grab.”

- Force Application: The machine applies a pulling force to the sample until it breaks. The force and the elongation of the geotextile are recorded.

Significance:

- Strength Evaluation: It helps in assessing the strength characteristics of the geotextile, which are vital for their performance in real-world applications.

- Quality Control: This test is essential for quality control during the manufacturing of geotextiles.

- Design Information: Engineers use the data from this test to make informed decisions regarding the suitability of a geotextile for specific engineering projects.

The results from the grab tensile test provide crucial information about the mechanical properties of geotextiles, ensuring that they meet the required standards for strength and durability in their intended applications.

What is the standard test method for measuring the nominal thickness of geosynthetics?

The standard test method for measuring the nominal thickness of geosynthetics is typically performed according to ASTM D5199. This test method is designed to determine the thickness of geosynthetics under a specified pressure.

Key Aspects of ASTM D5199:

- Procedure: The geosynthetic sample is placed under a specified pressure (usually 2 kPa) and the thickness is measured using a gauge or caliper.

- Specimen Preparation: The test typically requires a sample size of 100 mm x 100 mm, although this can vary depending on the material and the equipment used.

- Measurements: Thickness measurements are taken at several locations on the sample to ensure accuracy, and the average thickness is calculated.

- Application: This test is applicable to various geosynthetics, including geotextiles, geomembranes, geogrids, and others.

This method provides a reliable way to determine the thickness, which is critical for understanding the performance characteristics of the geosynthetic material in various applications.

ASTM standards play a fundamental role in ensuring the quality and performance of geosynthetics in various engineering and construction applications. From the pull-out and grab tensile tests to measuring nominal thickness, these standards provide a framework for assessing the suitability and durability of geosynthetic materials. Understanding and adhering to these standards is essential for engineers, designers, and manufacturers alike to ensure that the geosynthetics used in projects meet the highest quality and safety criteria, ultimately contributing to the success and longevity of construction endeavors.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)