+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

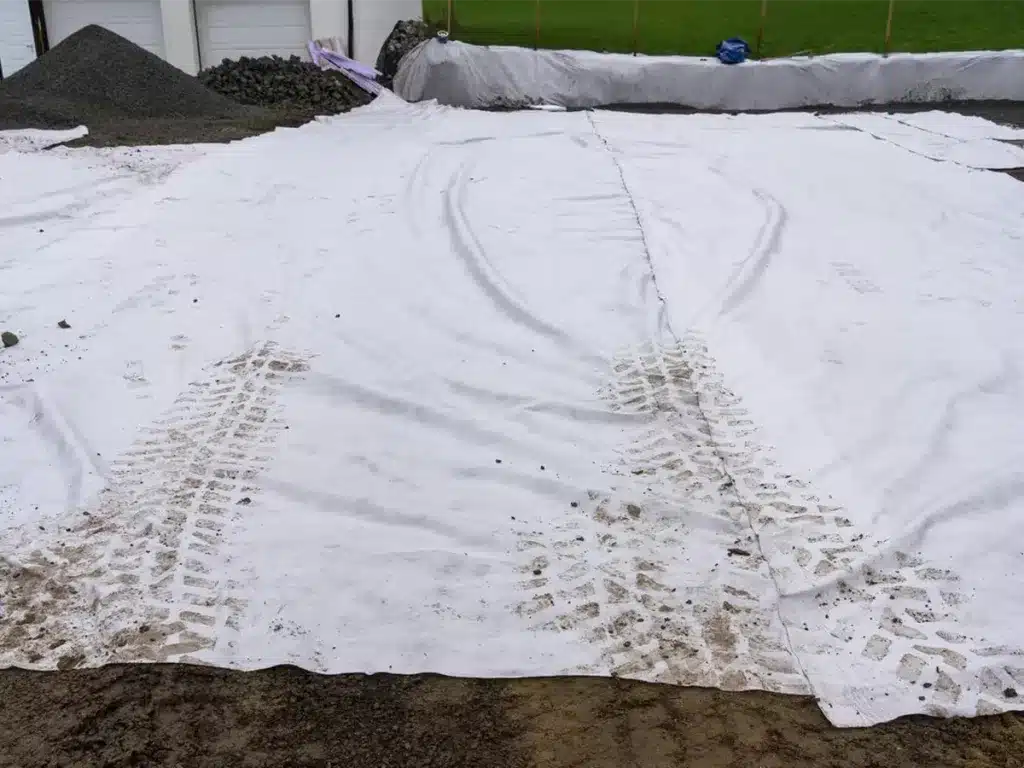

Non-woven geotextile fabric is a versatile and essential material in various engineering and environmental applications. Often used as filter cloth, this fabric plays a crucial role in managing soil erosion, drainage, and filtration. It is widely used in construction projects, landscaping, and environmental protection efforts. In this article, we will explore the specific uses of non-woven geotextile fabric, compare it to woven alternatives, and address its benefits as a filter fabric.

Is Geotextile Fabric the Same as Filter Fabric?

Yes, geotextile fabric is often referred to as filter fabric, particularly when it is used in applications that require filtration. “Filter fabric” is a generic term used to describe geotextiles whose primary function is allowing water to pass while keeping soil fines from migrating through the fabric. Geotextile fabric, whether woven or non-woven, is designed to perform various functions such as separation, reinforcement, and filtration. When used as a filter fabric, it allows water to pass through while trapping soil particles, thereby preventing erosion and maintaining the stability of soil structures. The term “filter fabric” highlights the specific application of the geotextile in filtering processes.

What is Non-Woven Geotextile Fabric Used For?

Non-woven geotextile fabric is used for a variety of applications, particularly in civil engineering, landscaping, and environmental projects that require protection, filtration, separation, and drainage. Its primary functions include separation, filtration, and drainage. In road construction, it is placed between soil layers to prevent mixing and to enhance drainage. In landscaping, non-woven geotextile fabric is used to control soil erosion and as a protective layer in retaining walls. Additionally, it is employed in drainage systems to allow water to pass through while filtering out debris and fine particles, making it an ideal material for filter cloth.

Why Are Nonwoven Filter Fabrics Preferred Over Woven Filter Fabrics?

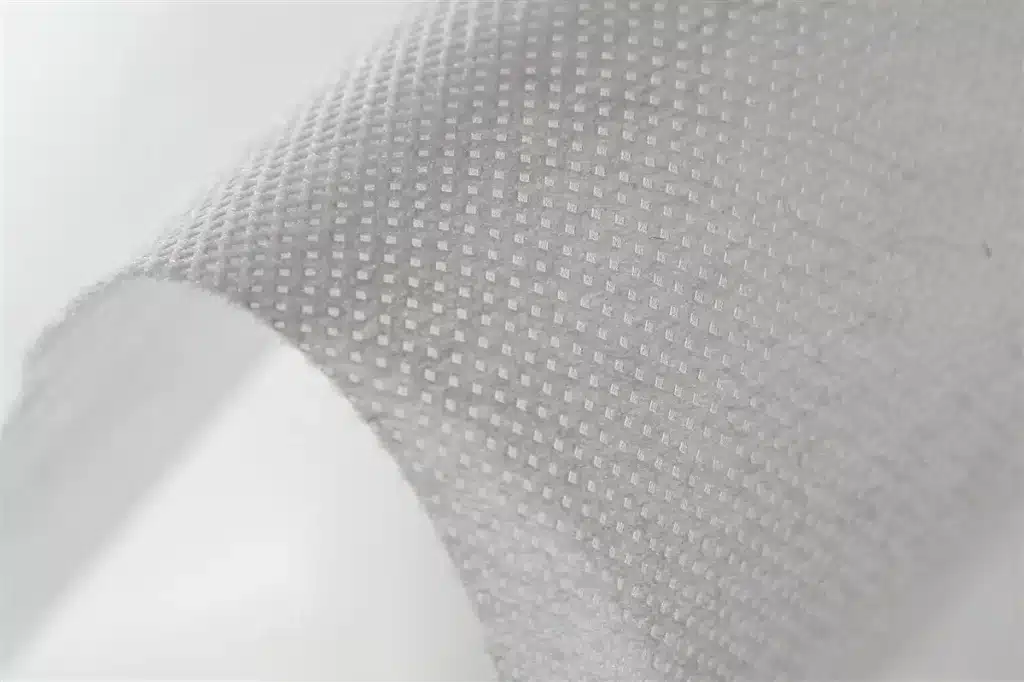

Nonwoven filter fabrics are often preferred over woven filter fabrics due to their superior filtration capabilities and flexibility. Non-woven fabrics have a more uniform structure, offering greater permeability, greater specific surface area, and controllable pore size distribution, as well as smaller pore sizes, which allow for better filtration of fine particles and more consistent water flow. They are also more flexible, making them easier to install in complex or irregular surfaces. Additionally, non-woven fabrics are typically thicker and provide better protection against punctures, making them more durable in challenging environments. These characteristics make nonwoven fabrics more suitable for applications where effective filtration and adaptability are critical.

Which is Better: Woven or Nonwoven Geotextile?

The choice between woven and nonwoven geotextile depends on the specific application and the desired outcomes. Woven geotextiles are generally stronger and more durable, making them ideal for applications requiring reinforcement and high tensile strength, such as road construction and embankments. On the other hand, non-woven geotextiles are better suited for filtration, drainage, and separation tasks due to their higher permeability and flexibility. However, it’s important to note that non-woven geotextiles break down much faster than woven geotextiles. For applications like filter cloth, where filtration efficiency and adaptability to various terrains are essential, non-woven geotextiles are often the better choice despite their shorter lifespan.

Non-woven geotextile fabric serves as an effective filter cloth in various engineering and environmental applications. It is widely used for filtration, drainage, and soil stabilization. While both woven and non-woven geotextiles have their unique advantages, non-woven fabrics are often preferred for filtration tasks due to their superior permeability, flexibility, and durability. Understanding the specific needs of your project will help determine whether woven or non-woven geotextile is the right choice, ensuring optimal performance and long-term success in your construction or landscaping endeavors.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)