+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

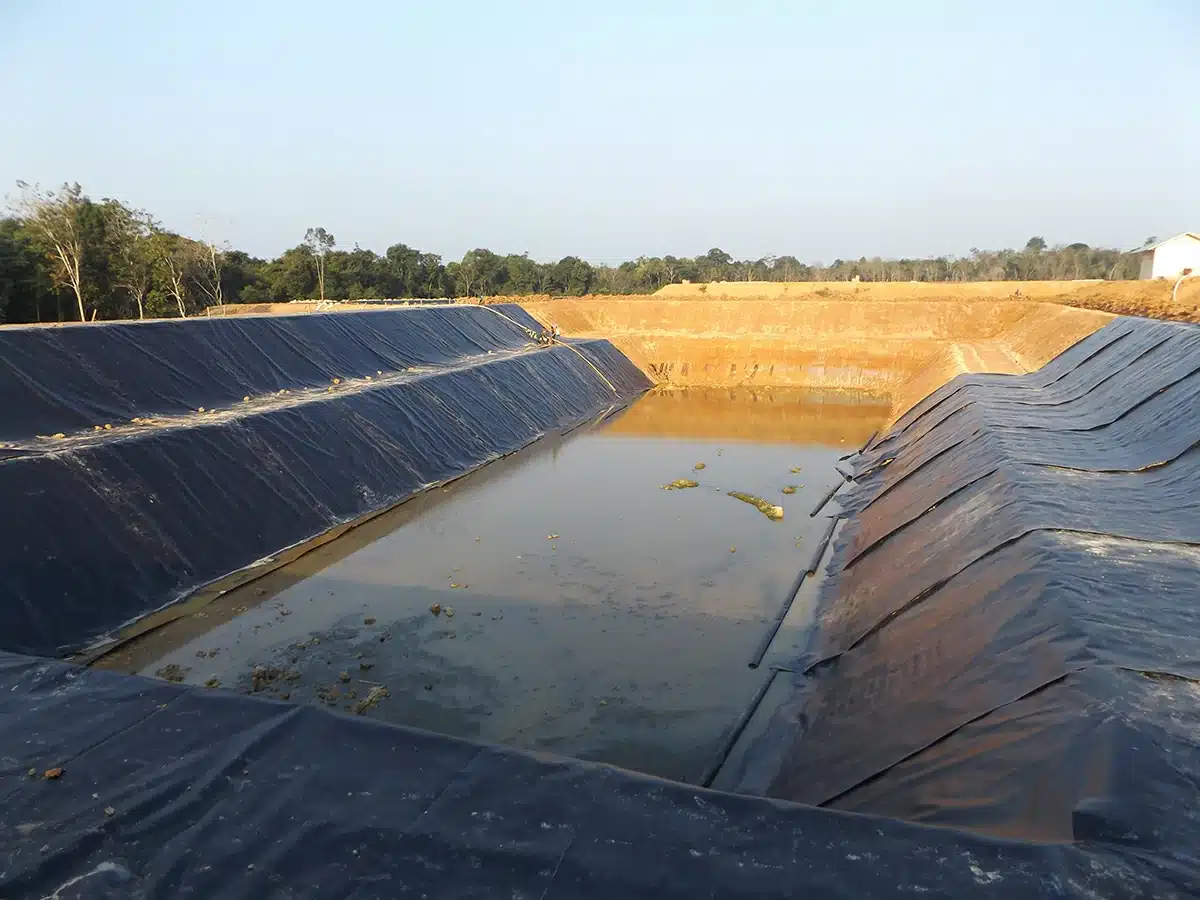

When it comes to geosynthetics, geomembranes play a crucial role in various industries, from environmental protection to construction. Geomembranes are impermeable synthetic liners used to control the movement of liquids or gases in containment structures like landfills, ponds, and tanks. If you’re considering using geomembranes for a project, one of the first things you’ll likely need to understand is the geomembrane sheet price. The cost can vary significantly based on several factors such as thickness, material type, and specific use cases. In this article, we’ll explore key questions that affect pricing and provide insights into geomembrane usage, thickness, and more.

How thick is a geomembrane sheet?

Geomembrane sheets come in a range of thicknesses, typically from 0.5 mm to 3.0 mm (20 mils to 120 mils). The most common thicknesses for geomembranes fall between 0.75 mm and 1.5 mm (30 to 60 mils). The thickness you choose depends on the type of application and the level of durability required. Thicker geomembranes are often used for applications that involve higher pressure, heavier loads, or harsh environmental conditions.

Factors that affect thickness:

- Pressure and load-bearing capacity: Thicker sheets, generally in the range of 1.5 mm to 3.0 mm, are needed for projects like landfill liners or pond linings, where the geomembrane must resist significant pressure from liquid or earth.

- Chemical resistance: For projects involving harsh chemicals or aggressive contaminants, thicker sheets (closer to **1.0 mm to 3.0 mm**) provide better resistance and protection.

- Cost considerations: While thicker geomembranes are more durable, they also tend to be more expensive, which may influence project budgets.

What is the difference between GCL and geomembrane?

While both Geomembranes (GM) and Geosynthetic Clay Liners (GCL) serve similar functions in terms of containment, they are quite different materials.

- Geomembranes (GM): These are impermeable synthetic liners, usually made from materials such as HDPE (High-Density Polyethylene), LLDPE (Linear Low-Density Polyethylene), PVC, or EPDM. Geomembranes are widely used for containment and separation in various applications, including landfill liners, pond liners, and canal liners.

- Geosynthetic Clay Liners (GCL): GCLs are made of a thin layer of bentonite clay between two layers of nonwoven geotextiles. The bentonite layer provides natural impermeability, while the fabric helps to hold the clay in place. GCLs are often used as a more cost-effective alternative to geomembranes in situations where the primary function is containment and minimal resistance to external pressure is required.

Key differences:

- Material: Geomembranes are synthetic, while GCLs use natural clay as a key component.

- Applications: Geomembranes are used in a wider variety of high-pressure applications, while GCLs are typically used in lower-pressure settings, such as under roadways or for secondary containment.

How to use geomembranes?

Geomembranes are used in a variety of construction and environmental applications to prevent fluid migration and control contamination. Here’s a general overview of how they are typically used:

- Site preparation: The installation area must be cleared of any debris, sharp objects, and irregularities that could puncture or damage the geomembrane.

- Laying the membrane: Geomembranes are typically laid out in large sheets across the prepared surface. They are then welded or joined together to create a continuous, impermeable barrier. Specialized equipment is used to ensure tight seams and to avoid leakage. Geomembranes are commonly used as liners for various waste conveyance canals, providing effective containment and preventing leakage into surrounding environments.

- Anchoring: To secure the geomembrane in place, anchor trenches or ballast are used along the edges. In some cases, additional protective layers are added to shield the geomembrane from mechanical damage or UV degradation. Geomembranes also serve as waterproofing liners within tunnels and pipelines, offering crucial protection against water seepage and contamination.

- Testing: After installation, geomembrane systems are tested for leaks and integrity, often using methods such as vacuum box testing or electrical leak detection. In the agriculture industry, geomembranes are utilized as liners for irrigation systems or agricultural ponds, helping conserve water and prevent soil contamination. Additionally, geomembranes play an important role as liners for potable or reserve water, such as in the safe shutdown of nuclear facilities, where containment is critical for public safety and environmental protection.

What is geomembrane used for?

Geomembranes are versatile materials with a wide range of uses, primarily for containment and protection in civil engineering and environmental projects. Here are some of the most common applications:

- Landfill liners: Geomembranes are essential for lining landfills to prevent leachate (contaminated water) from seeping into the surrounding soil and groundwater, and to control fluid migration in a manmade project, structure, or system.

- Pond and reservoir liners: In ponds, agricultural reservoirs, and fish tanks, geomembranes are used to prevent water from escaping or infiltrating, helping to control fluid migration in a manmade project, structure, or system.

- Wastewater treatment: Geomembranes are used in wastewater treatment plants to create barriers between different stages of treatment and prevent contamination, to control fluid migration in a manmade project, structure, or system.

- Mining: In the mining industry, geomembranes are used to line tailings ponds and heap leach pads to contain hazardous liquids, and to control fluid migration in a manmade project, structure, or system.

- Canals and irrigation: Geomembranes are applied to canals to prevent water loss due to evaporation or seepage, improve water conservation efforts, and control fluid migration in a manmade project, structure, or system.

The geomembrane sheet price depends on various factors, including the thickness, material, and specific use case. When selecting a geomembrane, it’s crucial to consider the application’s requirements for durability, chemical resistance, and load-bearing capacity. While geomembranes and geosynthetic clay liners (GCLs) serve similar purposes, geomembranes offer more flexibility and strength for high-pressure applications. Whether you’re lining a landfill or constructing a pond, understanding the installation process and the wide-ranging applications of geomembranes will help you make the best material choice for your project.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)