+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geomembran plays a critical role in modern geosynthetics, offering essential containment solutions across various civil and environmental engineering projects. As the demand for sustainable infrastructure grows, geomembran products are becoming increasingly vital due to their durability, chemical resistance, and waterproofing capabilities.

What is a Geomembran and How is it Used in Geosynthetics?

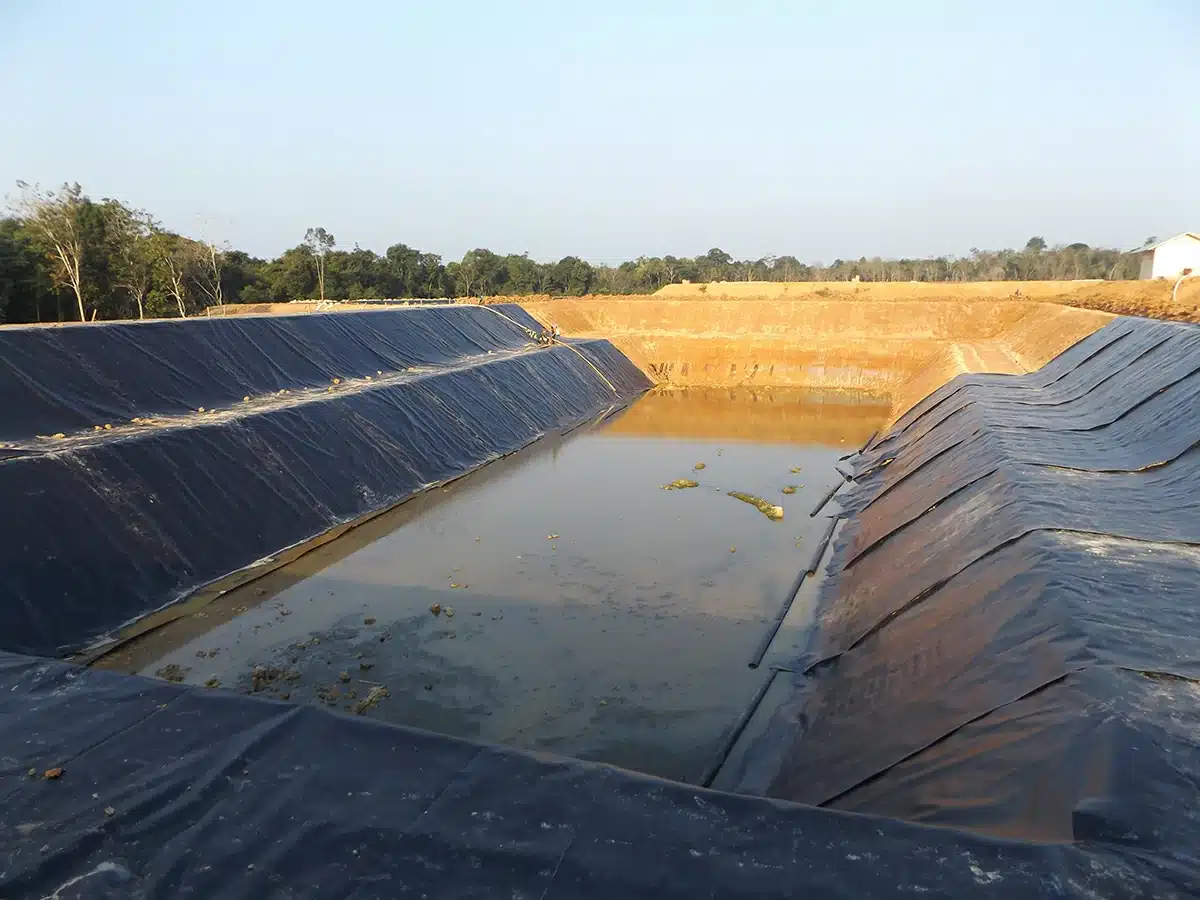

A geomembran is a low-permeability synthetic liner or barrier, often made from HDPE (high-density polyethylene), LLDPE, or PVC, designed to control fluid or gas migration in projects involving soil, rock, or waste containment. In the geosynthetics industry, geomembrans are used in:

- Landfills (as bottom liners and cover systems)

- Mining operations (heap leach pads)

- Water reservoirs and canals

- Wastewater treatment facilities

These liners ensure environmental protection by preventing hazardous materials from seeping into groundwater or surrounding soils.

What Makes Geomembrans Essential in Environmental Engineering?

The effectiveness of geomembran in environmental protection lies in its combination of strength, chemical resistance, and low permeability. When used properly, they:

- Extend the life of waste containment systems

- Prevent leakage in water reservoirs

- Reduce environmental risk from industrial chemicals

According to a 2024 market report by MarketsandMarkets, the geomembranes market is projected to reach USD 3.7 billion by 2029, growing at a CAGR of 6.4% from 2024 (Source: MarketsandMarkets, Geomembranes Market 2024–2029).

What Are the Key Standards and Tests for Geomembran Performance?

To ensure reliability, geomembrans undergo rigorous industry testing based on ASTM and ISO standards. Key parameters include:

- Tensile strength (ASTM D638)

- Puncture resistance (ASTM D4833)

- Permeability (ASTM D4491)

- UV resistance (ASTM D4355)

These tests guarantee that geomembrans meet safety and performance requirements for long-term deployment in harsh environments.

How is the Global Demand for Geomembrans Changing?

Global infrastructure investments, stricter environmental regulations, and the expansion of mining and energy sectors are fueling increased demand. For instance:

The Asia-Pacific region accounted for over 38% of global geomembran consumption in 2023, driven largely by China and India’s large-scale infrastructure projects (Source: GlobalData, Geosynthetics Market Trends 2023).

Additionally, the shift toward sustainable construction materials boosts the adoption of geosynthetics, with geomembran products at the forefront of this transformation.

As geosynthetics continue to shape the future of civil and environmental engineering, geomembran stands out as a cornerstone material. With a proven record of performance and growing market relevance, it remains an indispensable solution for infrastructure resilience and environmental protection.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)