+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

When constructing a retaining wall, selecting the right material is crucial for both structural integrity and longevity. An uniaxial geogrid, a popular choice among engineers and architects, offers exceptional reinforcement for soil stabilization projects. This article explores why a uniaxial geogrid is considered one of the best materials for retaining walls and addresses common questions about its usage, effectiveness, and installation specifics.

What Type of Geogrid is for Retaining Walls?

When it comes to selecting a geogrid for retaining walls, the choice largely depends on the specific requirements of the wall, such as the height, the type of soil, and the load it needs to support. Here are the primary types of geogrids used for retaining walls:

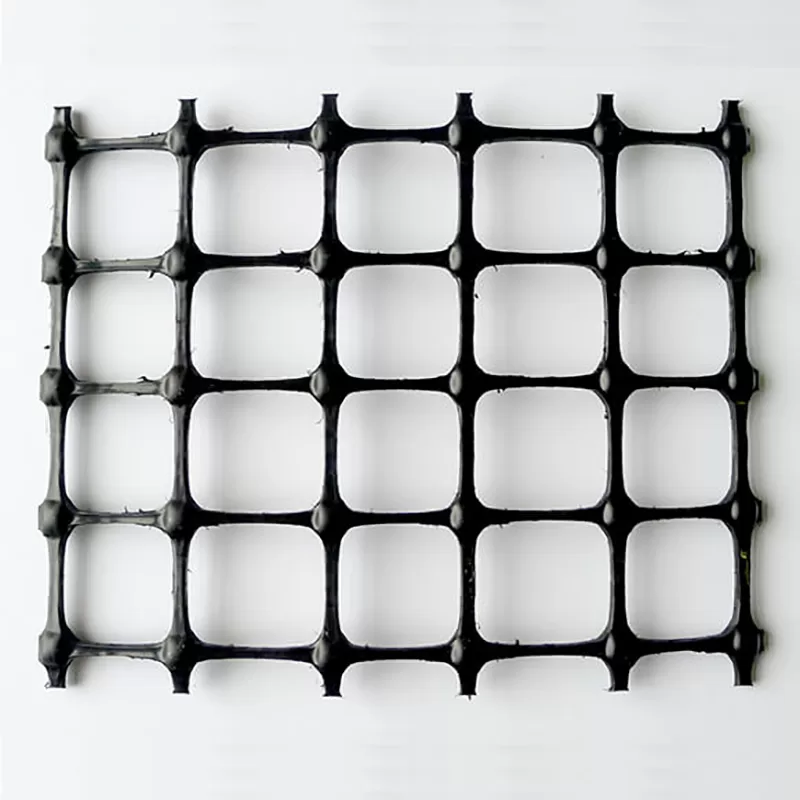

Uniaxial Geogrids

- Purpose: Uniaxial geogrids are designed to withstand high tensile loads in one direction, making them ideal for reinforcing retaining walls where the primary force is exerted horizontally.

- Application: These are commonly used in walls where the reinforcement is needed to resist lateral earth pressures and prevent wall failure.

Biaxial Geogrids

- Purpose: Biaxial geogrids provide tensile strength in both the longitudinal and transverse directions. This makes them versatile for applications where reinforcement in multiple directions is needed.

- Application: Although not as commonly used in retaining walls as uniaxial geogrids, they can be used in situations where the wall may experience stress from various directions.

High-Strength Geogrids

- Purpose: These geogrids are made from high-tensile materials like polyester or polypropylene, offering exceptional strength and durability.

- Application: High-strength geogrids are suitable for retaining walls that are very tall or need to support heavy loads, ensuring long-term stability and performance.

Composite Geogrids

- Purpose: Composite geogrids combine the benefits of geogrids with non-woven geotextiles to provide reinforcement and separation in one product.

- Application: These are used in retaining walls where both soil reinforcement and separation are needed, improving overall wall stability and drainage.

Selecting the Right Geogrid

When choosing a geogrid for a retaining wall, consider the following factors:

- Wall Height: Taller walls typically require stronger, uniaxial geogrids.

- Soil Type: Cohesive soils may require different geogrids compared to granular soils.

- Load Requirements: Walls supporting heavy loads, such as those near roads or buildings, might need high-strength geogrids.

- Environmental Conditions: Consider resistance to UV exposure, chemical attack, and temperature variations.

Consulting with a geotechnical engineer is advisable to ensure the appropriate geogrid is selected based on the specific conditions and requirements of your retaining wall project.

What Material is Geogrid?

What Material is Geogrid?

Geogrid is a type of geosynthetic material made from various polymers, specifically designed to reinforce soil, rock, or other geotechnical materials. The primary materials used in manufacturing geogrid include:

- Polypropylene (PP): A common polymer in geogrid, known for its strength and resistance to chemicals and UV degradation. Polypropylene geogrids are often used in applications requiring flexibility and resilience, such as in road construction and embankment reinforcement.

- Polyethylene (PE): High-density polyethylene (HDPE) is another popular choice for geogrid production. It provides excellent tensile strength and durability, making it suitable for long-term applications in soil stabilization and erosion control.

- Polyester (PET): Polyester geogrids are known for their high tensile strength and minimal elongation, making them ideal for reinforcing walls and slopes. They are particularly resistant to creep, maintaining their strength over time under load.

These polymers are processed into grids with open, mesh-like structures, allowing soil interaction and efficient load transfer in various civil engineering applications. Geogrids are primarily used in retaining walls, road construction, and slope stabilization due to their ability to strengthen and support the soil structure.

How Effective is Geogrid?

Geogrid is a highly effective material used in civil engineering and construction, especially for reinforcement, stabilization, and support in soil structures. Made from polymers, geogrids are installed to distribute loads over a large surface area, improving the overall strength of the construction. These grids come in different types such as uniaxial, biaxial, and triaxial, each designed to meet specific performance needs. Let’s explore how effective geogrids are in various applications.

- How does geogrid improve soil stability: Geogrids provide structural integrity by reinforcing the soil, making it more stable and less prone to erosion or displacement. When installed in layers, geogrids interlock with the surrounding material, creating a reinforced composite layer. This effect is especially important in areas with poor soil quality, where traditional construction methods might struggle to maintain stability. The geogrid effectively prevents lateral spreading of the soil and reduces settlement, resulting in a more stable foundation.

- Can geogrids handle heavy loads: Yes, geogrids are specifically designed to distribute heavy loads over a broader area, reducing stress on the soil. This characteristic is particularly beneficial in roadways, parking lots, and load-bearing retaining walls. By spreading the weight more evenly, geogrids minimize the risk of cracks, deformations, or shifting under pressure, making them crucial in load-bearing applications.

- Do geogrids prevent soil erosion: Geogrids are effective in controlling soil erosion, particularly on slopes and embankments. When placed in areas prone to surface erosion, geogrids help retain soil particles and vegetation, reducing water runoff and soil displacement. The grid structure allows for better root penetration, which further stabilizes the soil. This is a common practice in landscaping, road construction, and coastal management projects.

- How long does geogrid last: Geogrids are durable and long-lasting. Made from high-strength polymers, they resist degradation from chemicals, moisture, and ultraviolet (UV) exposure. This makes them ideal for both temporary and permanent installations. Depending on environmental factors and application conditions, geogrids can last several decades, ensuring that reinforced structures remain stable over time.

Summary:

Geogrids are highly effective in various applications, offering significant improvements in soil stability, load-bearing capacity, and erosion control. Their durability and long-lasting performance make them a preferred choice for infrastructure projects, especially in challenging soil conditions.

What is the Spacing for Geogrid in a Retaining Wall?

The spacing for geogrid in a retaining wall depends on various factors, including the height of the wall, the type of soil, the load it will bear, and the specific geogrid material used. However, here are some general guidelines:

- Wall Height: For a typical retaining wall, geogrid is often installed at vertical intervals ranging from 12 to 36 inches (30 cm to 90 cm). Taller walls may require closer spacing (e.g., 12–18 inches) to ensure adequate reinforcement, while shorter walls can use wider spacing.

- Soil Type: The type of soil behind the wall also influences the geogrid spacing. Poorer soil types like clay may need more frequent reinforcement layers, while well-draining soils like sand or gravel may allow for wider spacing.

- Load on the Wall: If the retaining wall is expected to bear heavy loads (such as from nearby vehicles or buildings), the geogrid layers should be spaced closer together for added stability.

- Design Specifications: Each project should follow design specifications provided by engineers or manufacturers. These specifications account for all factors such as wall height, slope, and load.

Example: For a 6-foot-high (1.8-meter) retaining wall with good soil conditions and moderate load, geogrid layers might be placed every 18 inches (45 cm) vertically. For a taller wall or higher load, closer spacing may be required.

Always refer to the manufacturer’s guidelines and, if needed, consult with a structural engineer to ensure the correct spacing for your specific application.

Geogrid is an excellent choice for those seeking a durable and effective material for retaining walls. Its various types are suited to different structural requirements, and its material properties make it highly resistant to environmental stressors. When installed with proper spacing, geogrid enhances the stability and longevity of retaining walls, making it a top recommendation for soil stabilization projects. Understanding these aspects can guide homeowners and contractors in making informed decisions when constructing retaining walls, ensuring safety, and efficiency in their projects.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)