+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Woven geomembranes are essential in various construction and environmental projects. This article dives into the world of woven geomembranes, covering the three types, and materials, and distinguishing them from geotextiles. Whether you’re a professional in the field or just curious about these crucial materials, read on to expand your knowledge.

What are the Three Types of Geomembrane?

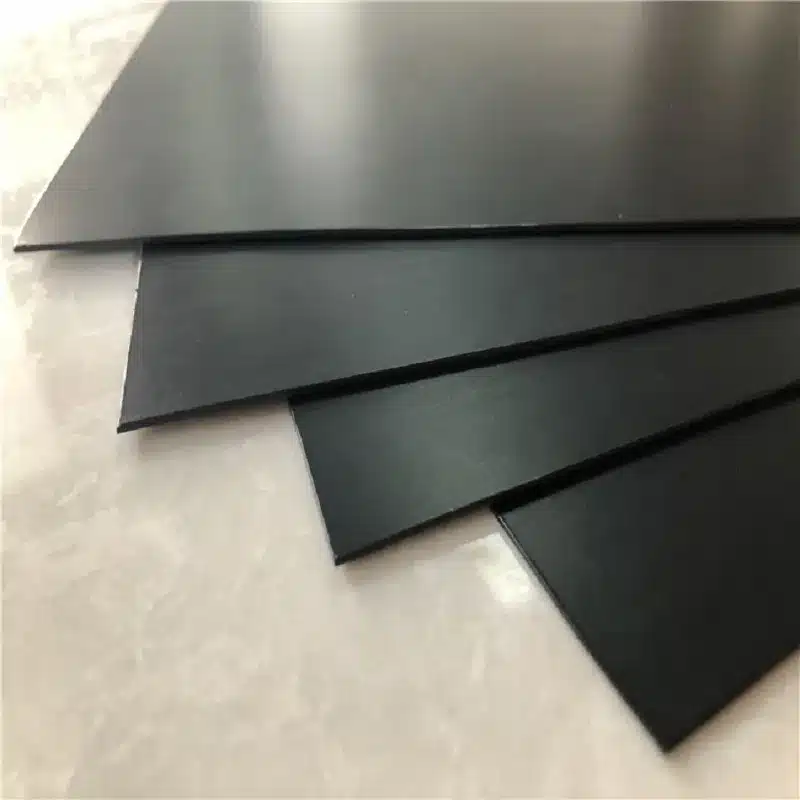

Thermoplastic Sheet Liners come in three main types:

- High-Density Polyethylene (HDPE): Known for its strong resistance to chemicals and long-lasting durability, HDPE liners are commonly employed in containment tasks such as lining landfills and industrial ponds.

- Linear Low-Density Polyethylene (LLDPE): Offering flexibility and remarkable puncture resistance, LLDPE liners are a top choice for applications where flexibility is essential, like decorative pond liners and secondary containment.

- Polypropylene (PP): Lightweight and highly resistant to UV radiation, PP liners are ideal for applications where UV exposure is a concern, such as outdoor pond liners and floating covers.

What are the Two Types of Geomembrane?

Geomembranes are categorized into two main types depending on their production process:

- Flexible Geomembranes: These are created by melting and extruding polymer sheets, with HDPE and LLDPE geomembranes usually belonging to this group. They are known for their even thickness and consistent properties.

- Nonflexible or Semicrystalline Geomembranes: This type is produced by passing softened polymer through heated rollers to form thin sheets. Polypropylene geomembranes are often made using this technique, and they may exhibit variations in thickness and properties when compared to flexible geomembranes.

What is Geomembrane Material?

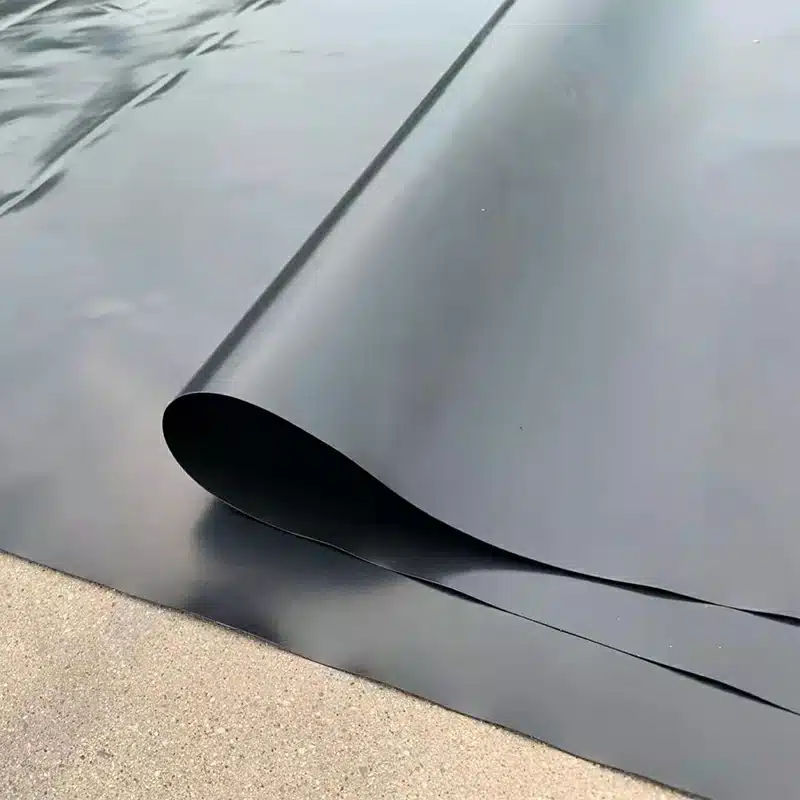

Geomembranes are synthetic membrane liners or barriers used to control fluid migration in a manmade project, structure, or system. They are mainly crafted from durable synthetic materials such as polyethylene and polypropylene, which are selected for their durability, chemical resistance, and flexibility. The choice of material typically hinges on the specific application, with HDPE, LLDPE, and PP being the most frequently employed options.

What is the Difference between Geotextile and Geomembrane?

Geotextiles and geomembranes are both geosynthetics used in civil engineering and environmental projects, but they serve different purposes:

- Function: Geotextiles are fabrics designed to filter, separate, reinforce, or protect soil, while geomembranes are impermeable barriers used for containment and fluid control.

- Material: Geotextiles are usually made from woven or non-woven fabrics, while geomembranes are made from synthetic polymers like polyethylene or polypropylene.

- Applications: Geotextiles are commonly used in erosion control, road construction, and drainage systems. Geomembranes are used in applications like landfill liners, pond liners, and reservoirs where containment of fluids is crucial.

In conclusion, woven geomembranes play a pivotal role in various construction and environmental projects. Understanding their types, materials, and differences from geotextiles is essential for professionals and enthusiasts alike. Whether you’re safeguarding the environment or constructing infrastructure, woven geomembranes are an invaluable tool in your arsenal.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)