+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In the world of civil engineering and construction, innovative materials and techniques are continually evolving to enhance project efficiency, durability, and sustainability. One such material that has gained significant attention in recent years is polypropylene geogrid. This geosynthetic product offers a wide range of benefits, making it a valuable asset in various civil engineering applications. In this article, we’ll delve into the advantages of polypropylene geogrid and its role in modern construction projects.

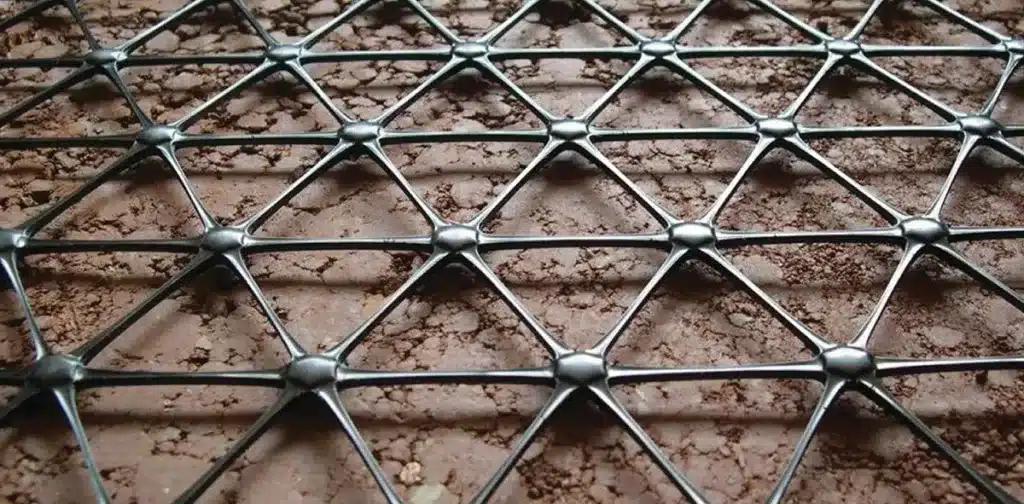

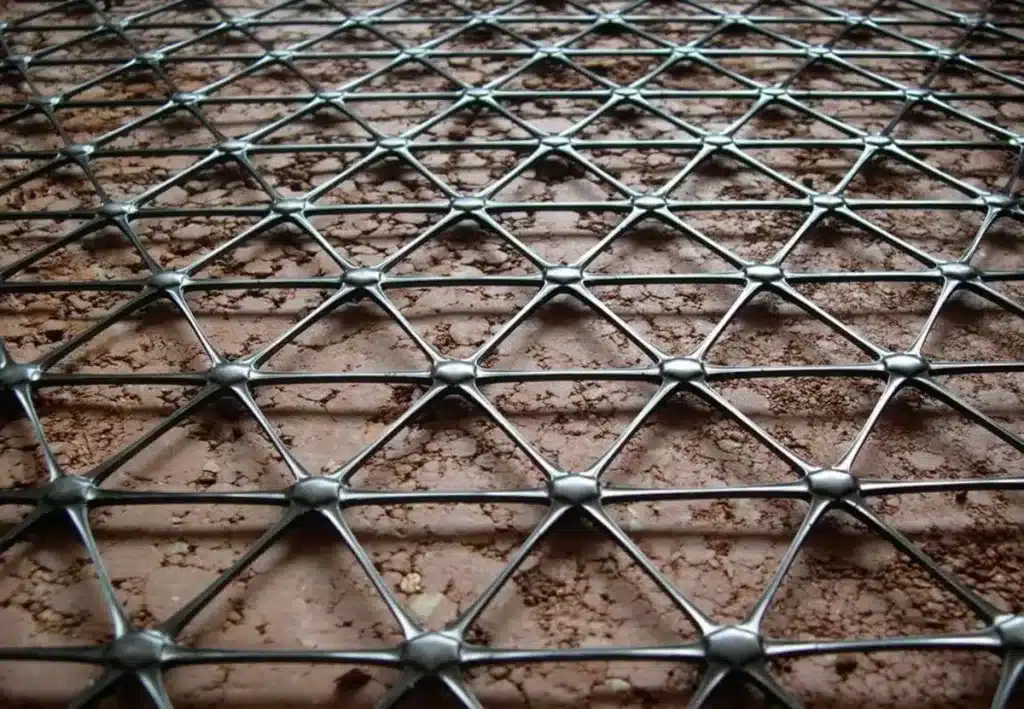

Polypropylene Geogrid: An Overview

Polypropylene geogrid is a geosynthetic material made from high-density polypropylene (HDPE) or polypropylene (PP). It is manufactured using a process that results in a grid-like structure with integral ribs. This design provides polypropylene geogrid with exceptional tensile strength and stiffness, making it ideal for reinforcement and stabilization applications in civil engineering.

Advantages of Polypropylene Geogrid:

- Enhanced Soil Stability: One of the primary uses of polypropylene geogrid is soil reinforcement. When placed within the soil, it effectively spreads the applied loads, reducing soil settlement and enhancing stability. This is particularly beneficial in retaining wall construction, slope stabilization, and road embankment projects.

- Improved Pavement Performance: Polypropylene geogrids are often used in the construction of roads and pavements. They help in distributing the load evenly, reducing the risk of cracking and rutting. This results in longer-lasting and more durable road surfaces.

- Quick Installation: The lightweight nature of polypropylene geogrids makes them easy to handle and install. This contributes to faster project completion, reducing labor costs and construction time.

- Corrosion Resistance: Polypropylene geogrids are highly resistant to chemicals and environmental factors, ensuring their long-term performance even in harsh conditions.

- Environmental Sustainability: Using polypropylene geogrids can minimize the need for additional construction materials and reduce soil excavation, making it an environmentally friendly choice.

What is a geogrid used for?

Geogrid is a geosynthetic material used in civil engineering and construction to create a reinforced coherent mass behind the retaining wall by stabilizing the soil. Its primary purpose is to enhance soil stability and prevent erosion by distributing loads and confining soil particles. Geogrids are commonly used in applications such as retaining walls, embankments, road construction, and slope stabilization to provide structural reinforcement and increase the overall stability and longevity of these structures.

What materials are geogrids?

Geogrids are constructed from a variety of materials, with some of the most commonly used ones being polyester, high-density polyethylene (HDPE), and polypropylene. These materials are selected for their excellent tensile strength and durability, making them suitable for reinforcing and stabilizing soil in various civil engineering and construction applications. Geogrids play a crucial role in enhancing the performance and longevity of structures like retaining walls, roadways, and embankments by providing structural support and soil reinforcement.

How does polypropylene geogrid compare to polyester or fiberglass geogrid for soil stabilization projects?

Polypropylene geogrid is known for its exceptional tensile strength and cost-effectiveness. However, comparing it to other geosynthetic materials depends on the specific project requirements. Polyester geogrids, for instance, may offer better chemical resistance in certain applications, while fiberglass geogrids may be preferred in extremely high-stress scenarios. A cost-benefit analysis and an evaluation of the project’s environmental factors should guide material selection.

Typical tensile strength range of polypropylene geogrids in civil engineering applications?

The tensile strength of polypropylene geogrids typically ranges from 20,000 to 80,000 pounds per foot, depending on the specific product and its intended use.

In conclusion, polypropylene geogrid is a versatile geosynthetic material that offers numerous advantages in civil engineering projects. Its ability to enhance soil stability, improve pavement performance, and provide quick installation makes it a valuable asset for engineers seeking cost-effective and sustainable solutions. However, careful consideration and proper installation techniques are essential to maximize its benefits in construction projects.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)