+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geogrids are essential materials used in civil engineering and construction to reinforce soils and improve stability. Among the various types, Plastic Geogrids and Polyester/Glass Fiber Geogrids are two popular options, each with unique properties and applications.

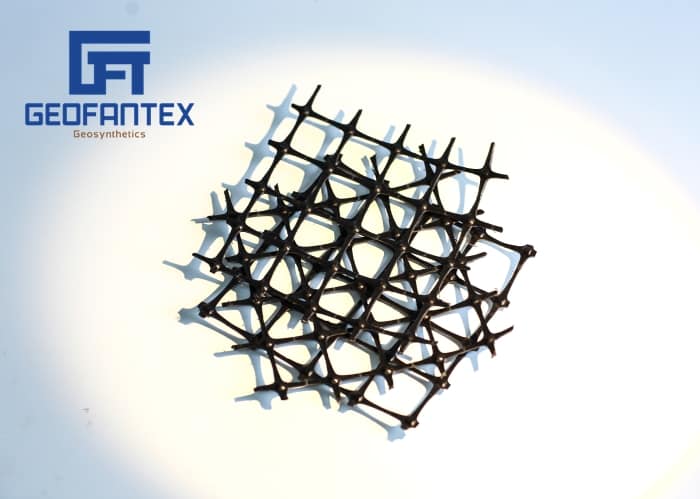

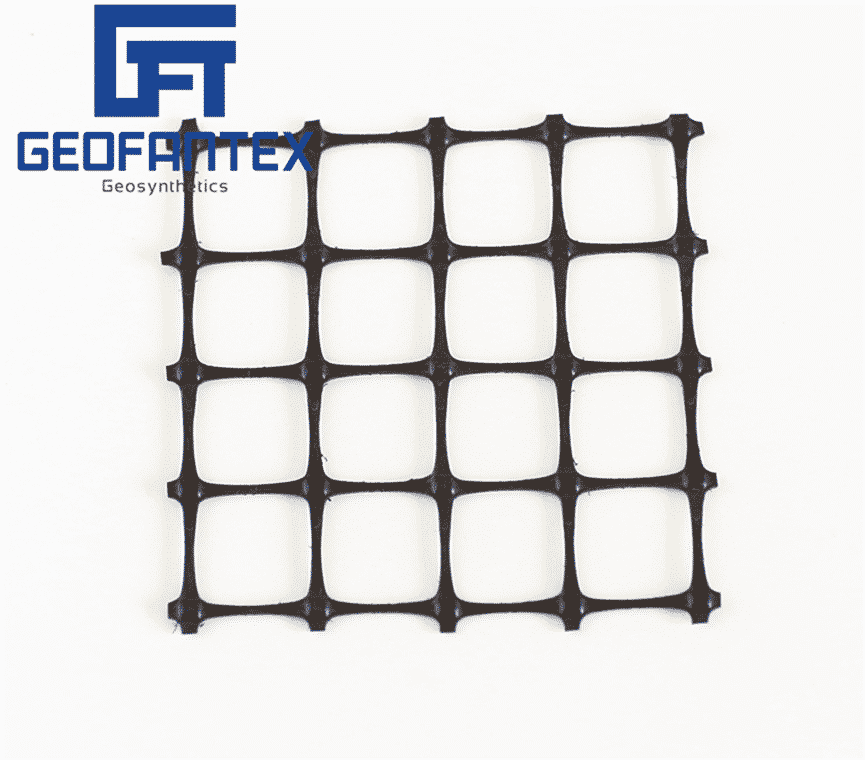

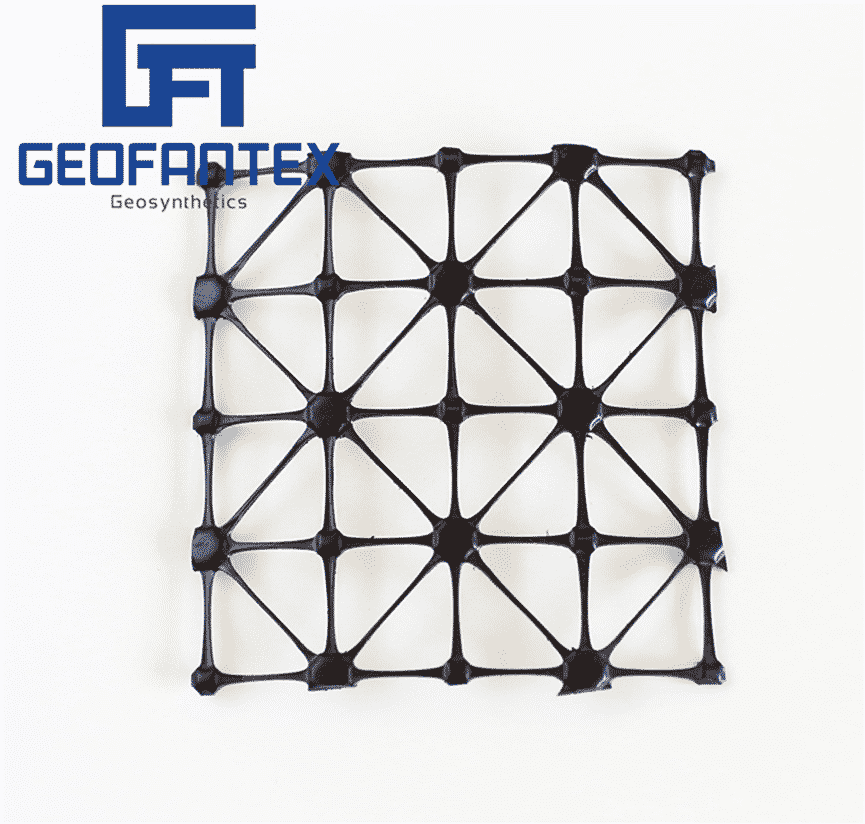

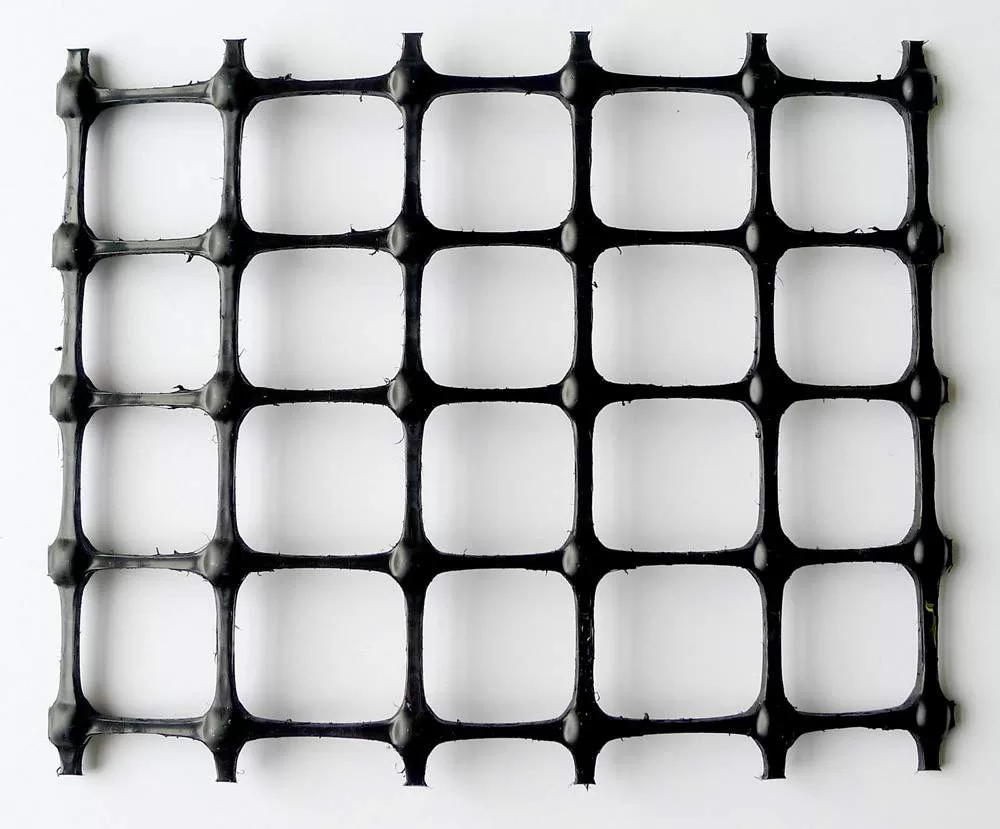

Plastic Geogrid

A plastic geogrid is a type of geosynthetic material made from polymers like polypropylene (PP) or high-density polyethylene (HDPE). It is designed with a grid-like structure of ribs and apertures, which provides reinforcement for soil, gravel, or other materials. Plastic geogrids are widely used in civil engineering projects to improve the performance and longevity of roads, retaining walls, embankments, and foundations.

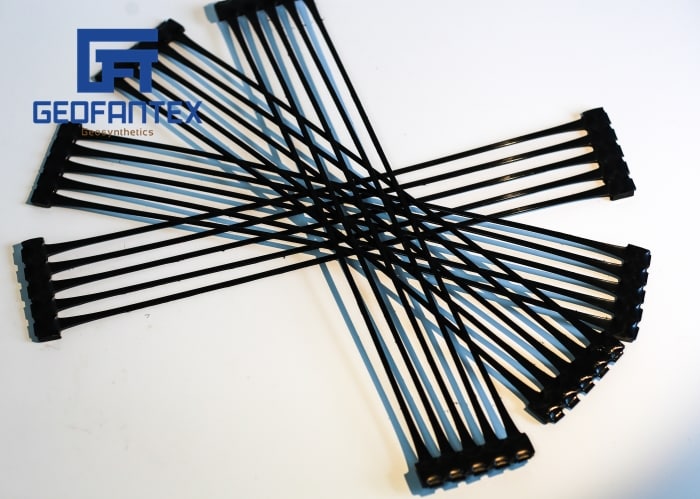

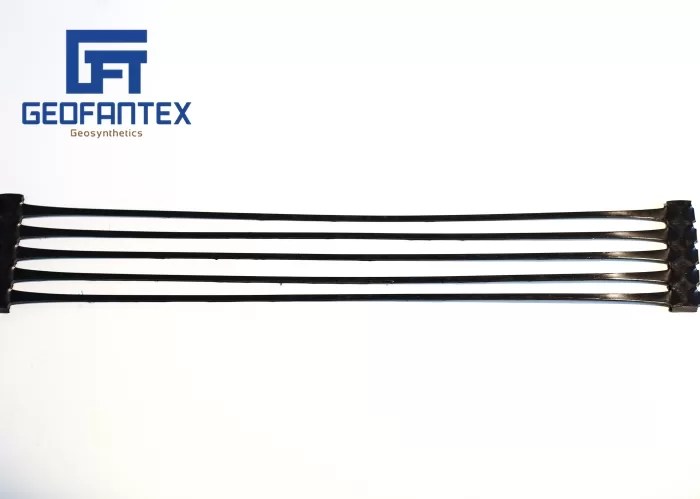

Polyester/Glass Fiber Geogrid

Polyester or glass fiber geogrids are manufactured using strong fibers embedded in a polymer matrix, providing higher tensile strength and durability than plastic geogrids. They resist stretching under heavy loads and are often used in large-scale infrastructure projects like highways, railways, and airport runways. These geogrids also offer excellent resistance to creep and environmental degradation.

Which geogrid type is better for heavy load-bearing projects?

Polyester or glass fiber geogrids are generally better for heavy loads due to their high tensile strength and low creep. They maintain performance over time under sustained pressure, making them suitable for highways and large infrastructure.

Are plastic geogrids cost-effective for small to medium projects?

Yes, plastic geogrids offer a good balance between cost and performance. They are lightweight, easy to install, and suitable for applications like residential retaining walls, landscaping, and minor road repairs.

How does environmental resistance compare between the two?

Plastic geogrids resist chemical corrosion well, but polyester/glass fiber geogrids provide better long-term resistance to UV exposure and temperature changes, which is crucial for projects exposed to harsh climates.

Can these geogrids be combined with other soil stabilization techniques?

Absolutely. Both types of geogrids work well with geotextiles, soil nails, and other reinforcement methods to enhance soil stability and improve construction outcomes.

Understanding the differences between plastic and polyester/glass fiber geogrids helps engineers and contractors choose the right product for their specific needs, ensuring cost efficiency and project durability. If you’re considering soil reinforcement or stabilization, exploring these geogrid options can make a significant difference in your project success.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)