+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

HDPE Uniaxial Geogrid – GeoFanTex

- Brand GeoFanGrid® HD

- Product origin China

- Delivery time 7-14 Days

- Supply capacity 40′ HQ/ 7 Days

Product Details

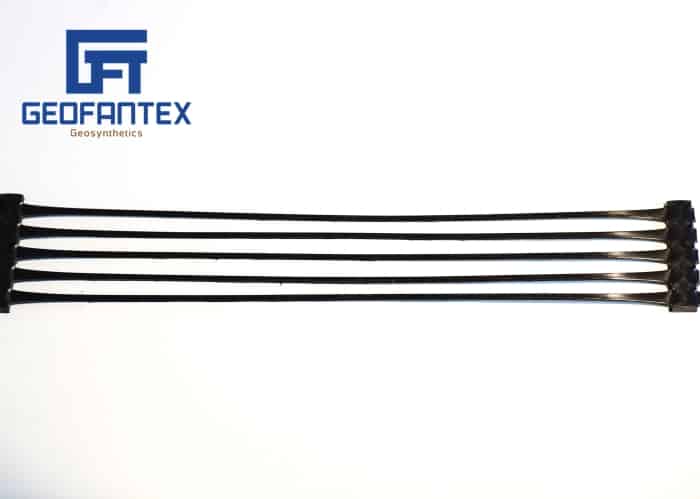

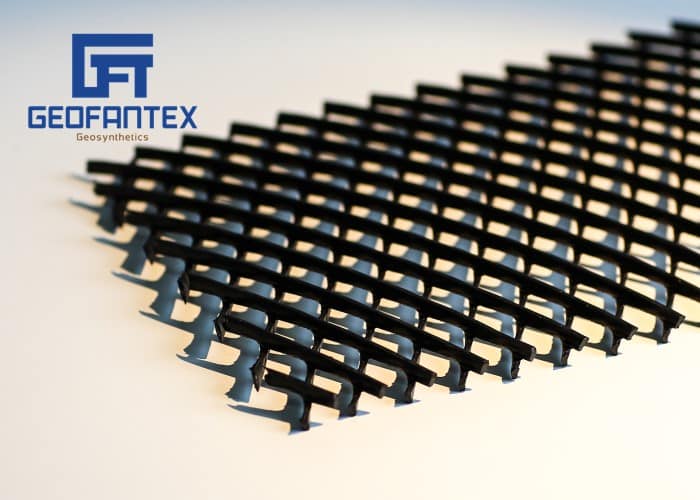

HDPE Uniaxial Plastic Geogrid

HDPE Uniaxial Plastic Geogrid (GeoFanGrid® HD) is manufactured from the most proven “punch-and-drawing” techniques with the most sophisticated manufacturing technology. Solid sheets of polymer have apertures removed by punching, and then the sheet is carefully stretched to achieve optimum molecular orientation within the monolithic polymer structure. Therefore high ultimate tensile strengths of up to 160kN/m can be achieved. HDPE Uniaxial Geogrid (GeoFanGrid® HD) is manufactured from High-Density Polyethylene. HDPE Uniaxial Geogrid (GeoFanGrid® HD) is manufactured through the process of extruding the sheet, punching the designed holes, heating while longitudinal stretching.

The Properties of GeoFanGrid® HD

( Plastic geogrids are many kinds according to the specifications, such as multiple geogrid, single geogrid, please click the other HDPE plastic geogrid. MINIMUM ORDER QUANTITY: 20’ft Container)

| Properties | Standard | Unit | HDPE 50 | HDPE 65 | HDPE 80 | HDPE 100 | HDPE 120 | HDPE 160 |

| Carbon Black Content | ASTM D 4218 | %(≥) | 2 | 2 | 2 | 2 | 2 | 2 |

| Tensile Strength | ASTM D 6637 | KN/m(≥) | 50 | 65 | 80 | 100 | 120 | 160 |

| Strength at 2% Elongation | ASTM D 6637 | KN/m | 13 | 15 | 23 | 29 | 35 | 47 |

| Strength at 5% Elongation | ASTM D 6637 | KN/m | 25 | 35 | 44 | 55 | 65 | 85 |

| Elongation at Yield | %(≤) | 12 | 12 | 12 | 12 | 12 | 12 | |

| Reduction Factor for Creep for 114-year Design life (RFcr) | ASTM D 5262 | 2.23 | 2.23 | 2.23 | 2.23 | 2.23 | 2.23 | |

| Approx. Loading Q’ty Per 40’ HQ | m2 | 40,000 | 32,950 | 31,900 | 30,000 | 25,080 | 18,750 |

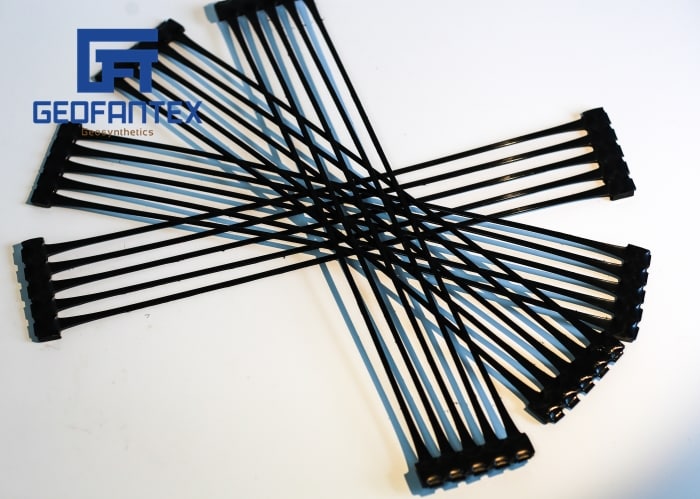

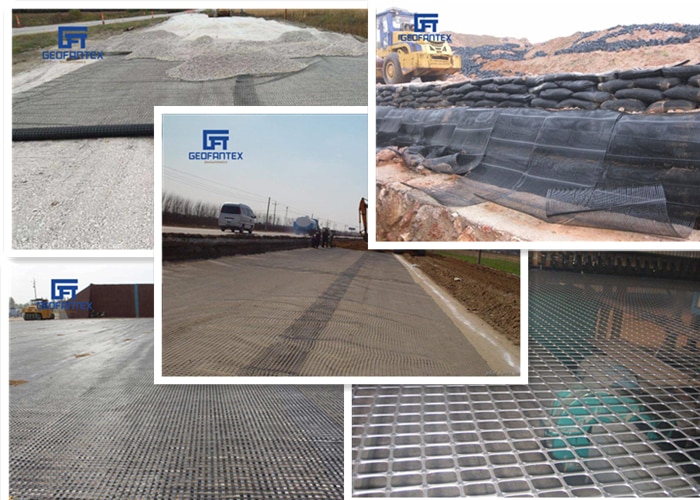

The Applications of HDPE Uniaxial Plastic Geogrid

The unidirectional plastic geogrid is a high-strength geosynthetic material. It is widely used in dams, tunnels, wharves, highways, railways, construction, and other fields.

HDPE Uniaxial Plastic Geogrid Role in engineering

- Strengthen the roadbed, which can effectively distribute the diffusion load, improve the stability and bearing capacity of the roadbed, and prolong the service life;

- Can withstand greater alternating loads;

- Prevent roadbed deformation and cracking caused by the loss of roadbed materials;

- Improve the self-supporting capacity of the fill behind the retaining wall, reduce the earth pressure of the retaining wall, save costs, extend the service life, and reduce maintenance costs;

- Combining the spray-anchored concrete construction method for slope maintenance can not only save 30%-50% of the investment, but also shorten the construction period by more than one time;

- Adding a geogrid to the roadbed and surface layer of the highway can reduce deflection, reduce rutting, delay the appearance of cracks by 3-9 times, and reduce the thickness of the structural layer by 36%;

- Applicable to all kinds of soil, no need to obtain materials from other places, saving labor and time;

- The construction is simple and quick, which can greatly reduce the construction cost.

Geofantex Geosynthetics have to make a series of guarantee for our products both plant processing and selling out to our customers. The selling to you is the first step, the service and guarantee is our task. Geofantex Geosynthetics have an ISO Certificate to guarantee the raw material, the product processing, and the end product. From receiving your order to replacement and installation of the products, we have solved the problems in time if you need, whatever the quality and technics guideline or suggestions. Our company has been committed to supplying high-quality products with reasonable price and delivery in time.

GEOFANTEX has an on-site Manufacturing Quality Assurance Laboratory at the factory. GEOFANTEX maintains a high level of quality and up-to-the-minute results on finished products through a fully equipped, well-staffed, dedicated laboratory existing in each of the manufacturing facilities. Each facility follows the same guidelines for evaluating the quality of GEOFANTEX products and is capable of adapting to market-driven requirements.

A. Objective

The objective of the GEOFANTEX Quality Assurance program is to define the implementation of basic manufacturing quality assurance (MQA) procedures necessary to ensure the consistent production of quality products supplied to the geosynthetic market. Note that at this time, these procedures are limited to HDPE Uniaxial Geogrid.

B. Scope

In order to achieve GEOFANTEX’s stated purpose, a rigorous set of minimum standards and an effective test program to assure compliance have been established. These procedures and requirements are frequently reviewed and adjusted to assure compliance with current market demands and/or predetermined project specifications. These procedures assure that raw materials and process parameters are controlled to provide products complying with GEOFANTEX’s pre-defined minimum characteristics.

HDPE Uniaxial Geogrid PRODUCT IDENTIFICATION AND DOCUMENTATION

A. Roll Numbering

Each roll of Uniaxial Plastic Geogrid is assigned a unique roll number. The Quality Assurance Laboratory maintains records documenting the raw materials and resulting product quality information.

B. Approval Procedure

Results for each tested roll of the product are checked against both GEOFANTEX China standard and customer specifications for compliance. The Quality Assurance Laboratory approves those materials that meet these requirements for shipment.

C. Non-Conformance

Material that does not meet GEOFANTEX minimum standards is given a roll number but is rejected and not placed into inventory. The material is identified as scrap and will not be utilized. Material that meets GEOFANTEX minimum standards but does not meet a stricter customer specification is not allocated to that customer but is placed into inventory as GEOFANTEX standard material.

D. Documentation

Individual Quality Assurance Certificates are generated and supplied for each roll of HDPE Uniaxial Geogrid product to include all relevant quality assurance information about the material(s).

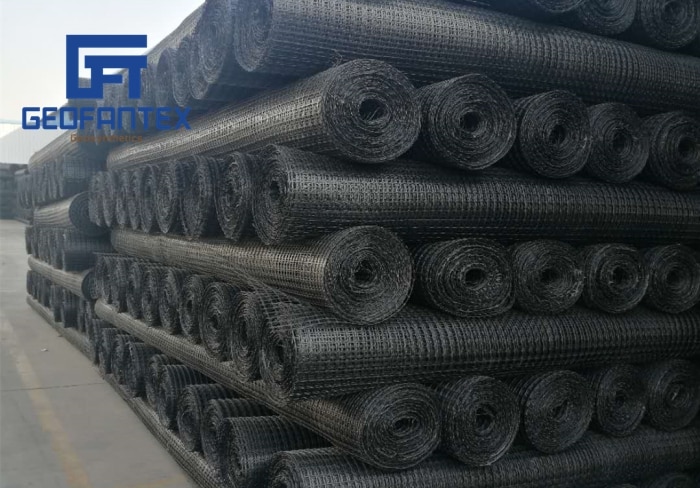

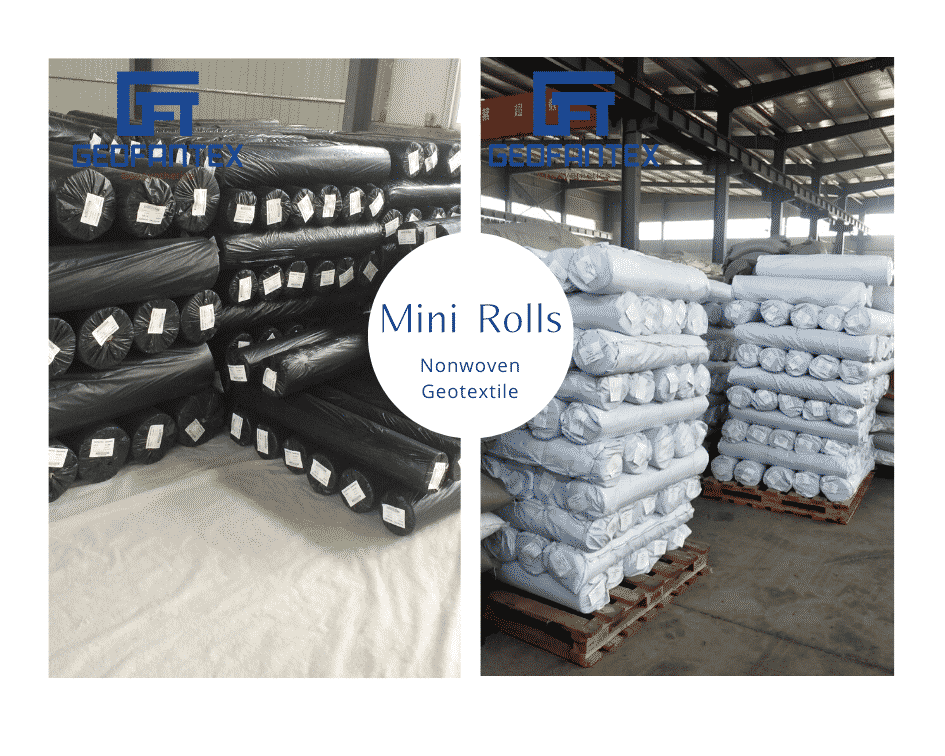

Geofantex Geosynthetics have a series of package and delivery service working procedures. Geofantex Geosynthetics have supplied thousands of containers to Latin America, North America, Southeast Asia, developed countries, and Africa within the past ten years. We provide the package of products with the rolls, pots, bags, sheets, or your requirement in orders. Our company has been committed to supplying high-quality products with reasonable price and delivery in time. Delivery one 40’HQ within 7 – 10 days. And we have an obligation in increasing loading quantity and make you save the freight costs maximumly. We supply the products by plane, by sea and land carriage to any regions or any countries of the worldwide, even the door-to-door service.

| SEPARATION | REINFORCEMENT | FILTRATION | DRAINAGE | WATERPROOF | PREVENTION | POLLUTION PREVENTION | PROTECTION | CONSOLIDATE | |

| GEOTEXTILE | √ | √ | √ | √ | √ | √ | |||

| GEOMEMBRANE | √ | √ | √ | ||||||

| GEOGRID | √ | √ | |||||||

| GEONET | √ | ||||||||

| GEOTUBE | √ | ||||||||

| GEOCELL | √ | √ | |||||||

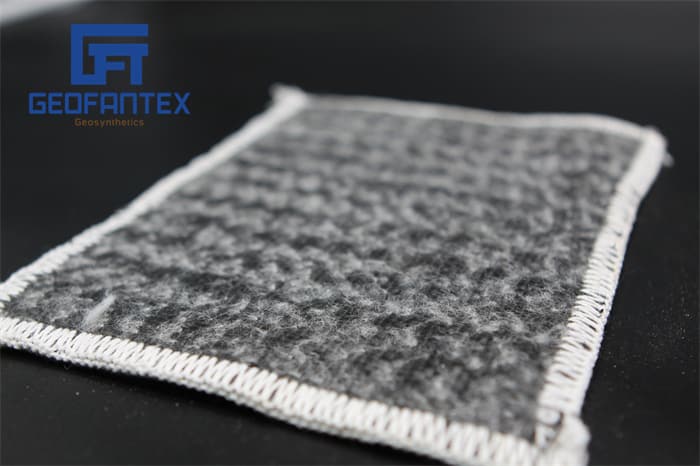

| GCL | √ | √ | |||||||

| GEOCOMPOSITE | √ | √ | √ | √ | √ | √ | √ | ||

| GEOCONCRETE BLANKET | √ | √ | √ | ||||||

| Drainage Board B | √ | √ | √ | √ | |||||

| Storage and Drainage Board | √ | √ | √ | √ | |||||

| Grass Paver | √ | √ | √ | √ | √ | √ | √ | ||

| Macmat | √ | √ | √ | √ | √ | √ | √ | ||

| GeoFanTex®GD 2L | √ | √ | √ | √ | √ | √ | |||

| GeoFanPipe® FP | √ | ||||||||

| GeoFanDrain® BC | √ | √ | √ | ||||||

| GeoFanPipe® DCP | √ | √ | |||||||

| GeoFanTRM® Geomantles | √ | √ | √ | √ | √ |

General Installation Guidelines

HDPE Uniaxial Geogrids are specifically designed to provide high tensile strength in one direction, making them ideal for reinforcing soil on slopes, embankments, and retaining structures. They effectively prevent soil movement, ground subsidence, and structural failure. Uniaxial plastic geogrids are widely used in highways, railways, bridge abutments, retaining walls, and other civil engineering projects where directional load support is critical.

Step 1: Storage and Handling

Store asphalt reinforcement rolls on a flat, dry surface, protect them from moisture and UV rays, handle them carefully, do not stack more than three high, and set aside damaged rolls.

Step 2: Surface Preparation

Prepare the pavement by repairing cracks and potholes, milling or leveling if necessary, and ensuring the surface is clean, dry, smooth, and even.

Step 3: Applying the bonding layer

Apply a uniform bituminous bond coat using the correct spray type and rate, allow the emulsion to fully break, and verify coverage with a test before complete installation.

Step 4: Installation/Placement

Install the asphalt reinforcement flat and wrinkle-free on a clean, dry surface, cut where necessary, use rollers or equipment to secure the bond, and restrict traffic to paving vehicles only.

Step 5: Joints and Overlaps

Place at least 4 to 6 inches of aggregate fill (thicker for soft soils), empty with slow-moving rubber-tired trucks if the subgrade is competent, compact using standard methods or static compaction for soft soils, ensuring adequate thickness to prevent rutting.

Step 6: Special Considerations

Address trenches, deep ruts, saturated subgrades, and repairs; repair damaged geogrid with a three-foot overlap; avoid tampering in extreme cold conditions; and prevent dynamic impacts in freezing conditions.

Geogrid Installation Guide

If you would like further information about the installation guide, please

Certificate

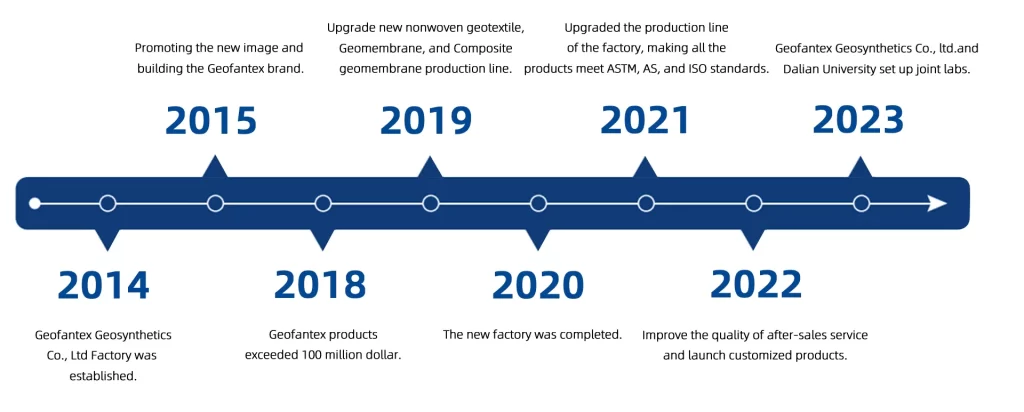

Development history of the company

Company Profile

Geofantex Geosynthetics Co., Ltd. is based in Dalian, a beautiful coastal city known for its excellent location and good transportation. Founded in 2014 with a registered capital of 5 million yuan, the company operates from an industrial park in Jinan, Shandong, covering over 50 acres. It features a modern office, advanced production equipment, and a skilled team in technical and management roles.

Geofantex has achieved ISO9001 and ISO14001 certifications and adheres to national standards to ensure product quality. Since its inception, the company has adopted advanced technologies and equipment, exporting products to regions like Australia, Canada, and Southeast Asia. Its export sales have reached significant figures, and customer feedback highlights our products’ stability, reliability, and cost-effectiveness.

The company leverages its innovative capabilities and market advantages, aiming to become a leading enterprise supported by national policies. Committed to “quality first” and “reputation first,” it emphasizes a people-oriented approach and values integrity, unity, and hard work. Geofantex seeks to collaborate with various engineering units to contribute to infrastructure development.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)