+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Whether you are building a home or an office, the need for geotextile material is growing. In fact, geotextile material is now used in everything from water treatment to fireproofing. And when it comes to purchasing, there are many different types of geotextile materials available on the market.

Geotextile Fabric

Originally called filter fabrics, geotextiles are synthetic permeable textiles used in road and earth structure construction. They are made from polyester or polypropylene. They can be used in applications such as filtration, separation, and drainage.

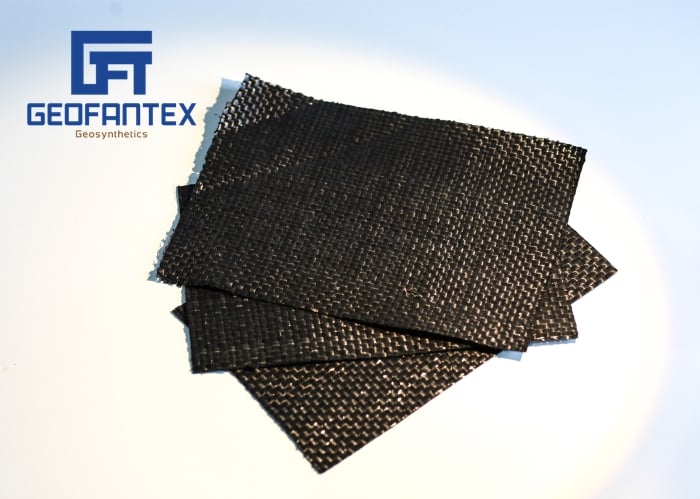

There are several different types of woven geotextiles. These include polypropylene, polyester, and coir. During the early days of the construction industry, geotextiles were not very popular. Several decades later, they have become a multibillion-dollar industry.

Woven geotextiles are made by weaving individual yarns on a loom. These fabrics are strong and durable. They are also resistant to UV degradation. This makes them ideal for long-term applications.

Woven geotextiles have low permeability. This makes them ideal for use in roads and driveways. They are also useful for preventing soil mixing. They can be installed with a small crew.

They also have excellent drainage capabilities. When installed properly, a layer of woven geotextile fabric placed over a three-inch base can increase the life of a surface by up to 50 years.

Geotextile Material

Usually, the geotextile material is composed of polyester or polypropylene fiber. These fibers have good adhesion, high strength modulus, and high resistance to UV radiation. Moreover, they are dimensionally stable, durable, and resistant to damage.

Woven geotextiles are usually used for separation and reinforcement. They have strong resistance to vertical and horizontal forces. Moreover, they are durable and low cost.

Nonwoven geotextiles are also available. They are composed of short fibers and are typically made of polypropylene, a crystalline thermoplastic, or polyamide, a synthetic fiber. They are also used in drainage and reinforcement.

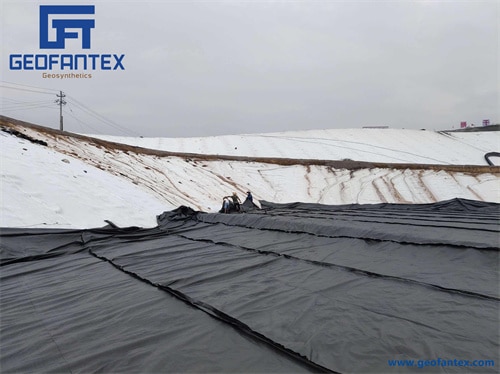

Geotextiles are used with soil to limit lateral movement of the subgrade. They act as a barrier between soil particles and soil, and also act as a moisture barrier. They can be heat bonded or stitched. They can also be used with rocks and other materials.

In order to determine the properties of a geotextile material, it is recommended to use various tests. Tests can include mechanical, physical, chemical, and endurance tests.

Geotextile Fabric

A geosynthetic material is a polymeric material used in the construction of civil engineering structures. Its main functions include filtration, drainage, reinforcement, protection, and waterproofing. Geotextiles are often used for pavements. The use of geotextiles is increasing as people become more aware of their benefits and use them in construction projects.

There are several types of geosynthetics, including geotextile fabrics and geofoam. Both types can be used for different applications. For example, geofoam and geocells are used in the construction of roads. They can also be used for filtration in the soil.

Geotextile fabric for driveway is the most widely used geosynthetic material and is used to construct road and railway infrastructures. However, it is important to understand its different functions before applying it. There are three main categories: passive, active, and smart. The passive type plays a passive role and provides the desired effect, whereas the active type creates change in its environment.

Non woven geotextile fabric

Unlike woven geotextiles, non woven geotextile fabric is lightweight and easy to cut. It is also highly water permeable, making it ideal for drainage applications. Besides drainage, it is also useful in filtration applications.

In order to know which type is the right one for your project, it’s important to understand the differences between the two. There are a few common misconceptions that may lead to confusion. Choosing the right product for your application will increase the overall design and performance of the project.

A non woven geotextile woven fabric is made from a continuous filament yarn, such as polypropylene, which is thermally fused. The fibers are then bonded with a binder to provide additional mechanical properties. The fabric is then finished with needle punching.

In order to determine which type of non woven geotextile fabric woven is right for your project, it’s important to consider the purpose of the fabric. The most common uses for non woven geotextile fabric are drainage and separation applications. This type of fabric is also used for erosion control and ground stabilization.

Geocomposite

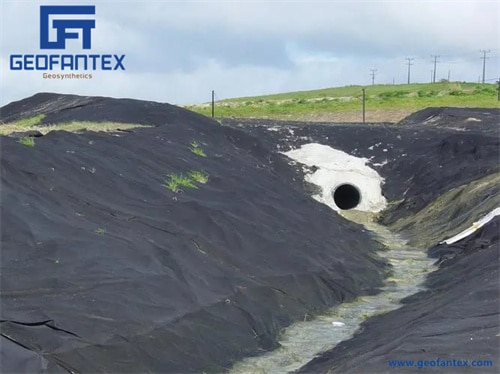

Compared to traditional granular materials, geocomposites are more durable. Geocomposites are also cost-effective. They can withstand heavy loads and can be used in civil and environmental works. They are also capable of reducing hydrostatic pressure. They also eliminate the risk of damage and leaks.

Geocomposites are formed by bonding two geosynthetic materials together. They combine the properties of both materials to create an impervious barrier. They are often used for drainage and filtration. They can also be used as a substrate for buildings.

Geocomposites have been used to intercept leachate from landfills. These systems have also been used to transmit vapor or water beneath pond liners.

Geocomposites are usually made from geonets and nonwoven geotextiles. These can be used to filter soil particles, provide drainage, and intercept leachate. They can also solve bearing problems on soft soils.

Geocomposites are available in several different styles. They can include geotextile-geogrid composites, which are used for drainage. They also include geosynthetic clay liners and three-dimensional polymeric cell structures.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)