+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In the evolving landscape of civil engineering and environmental management, the integration of advanced materials for sustainable and efficient construction has become paramount. Among these innovative solutions, the geocomposite layer stands out as a pivotal element in modern infrastructure projects. This article delves into the essence of geocomposite layers, exploring their functions, benefits, and distinctions from related materials, such as geocomposites vs geotextiles. By unraveling these layers, we aim to shed light on their significance in contemporary engineering practices.

What is a Geocomposite Drainage Layer?

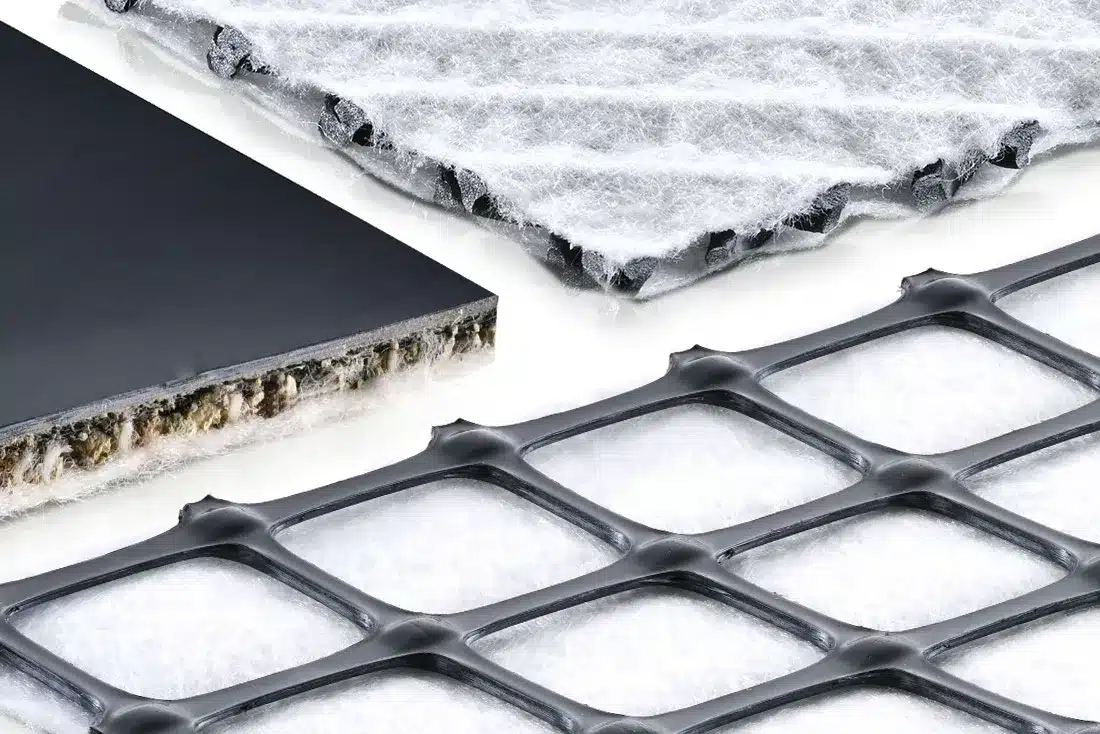

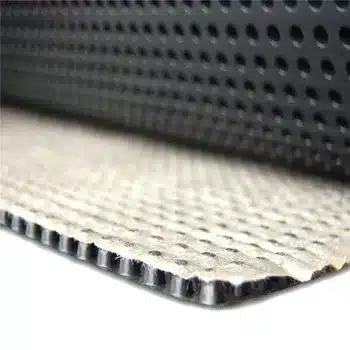

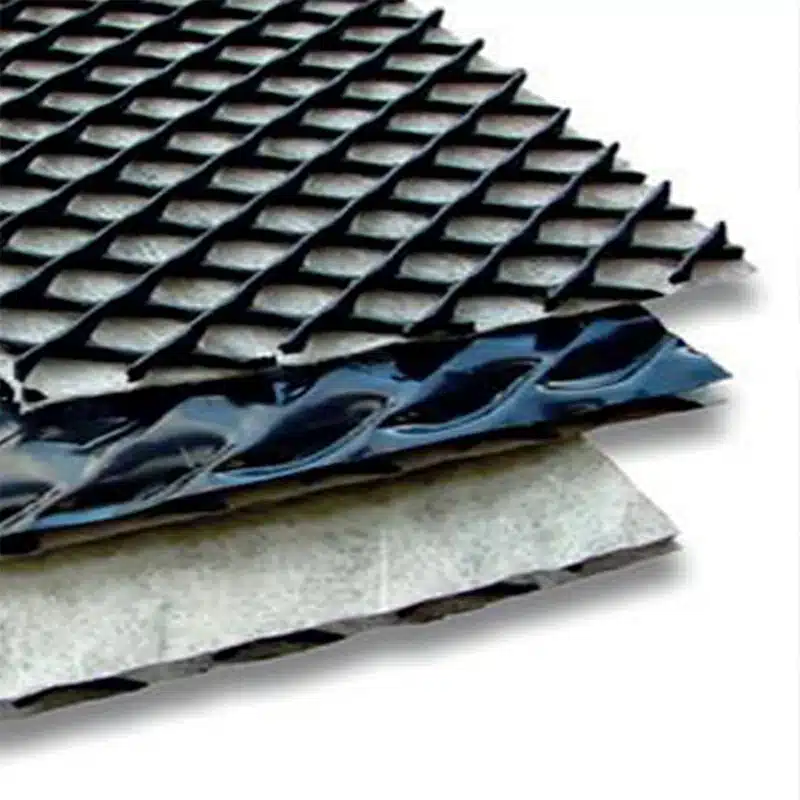

A Geocomposite Drainage Layer is a type of geosynthetic material designed to provide drainage in various applications, including road construction, landfills, and the construction of retaining walls. It typically consists of a combination of geotextiles and drainage cores, which work together to allow water to flow through the material while preventing soil particles from entering the drainage system.

The key features of a geocomposite drainage layer are:

- Drainage Core: Often made of a perforated plastic or polymer material, the core creates a network of channels that allows water to flow easily through the system.

- Geotextile Fabric: A nonwoven or woven fabric is often placed on both sides of the core. This fabric filters out soil and prevents clogging of the drainage channels while still allowing water to pass through.

- Durability: Geocomposites are engineered to be durable, resistant to chemical degradation, and stable under varying environmental conditions.

They are commonly used in construction and infrastructure projects, where efficient water drainage is necessary to prevent water accumulation and reduce the risk of erosion, structural failure, or damage to the environment.

What is the Function of Geocomposite?

Geocomposites are multi-layered materials that combine different geosynthetics, such as geotextiles, geomembranes, geonets, and geogrids. These materials are designed to take advantage of the specific properties of each component, allowing them to serve various functions in civil engineering applications. Here are some of the primary functions of geocomposites:

- Drainage: Geocomposites are commonly used for drainage applications to relieve hydrostatic pressure on structures like retaining walls, basements, and road subgrades. They allow for the easy passage of water while preventing the migration of soil particles.

- Filtration: In applications such as erosion control and stabilization of soil, geocomposites can prevent soil erosion by allowing water to pass through while retaining soil particles.

- Gas Venting: In landfill and mining applications, geocomposites are used to vent gases to prevent buildup and facilitate the migration of gases to treatment or exhaust systems.

- Waterproofing and Containment: Combined with geomembranes, geocomposites can act as barriers to water and other fluids, making them ideal for applications like landfill liners, pond liners, and contamination containment.

- Protection: When used in conjunction with geomembranes, geocomposites can protect more vulnerable materials from puncture, abrasion, or other physical damage.

- Reinforcement: By integrating geogrids, geocomposites can reinforce soil, enhancing the load-bearing capacity of roads and other structures.

Overall, geocomposites are versatile materials that solve multiple problems in geotechnical, transportation, environmental, and hydraulic applications through their multifunctional capabilities.

What is the Difference Between Geocomposite and Geotextile?

The main difference between geocomposites and geotextiles lies in their composition and intended applications:

- Geotextiles: These are synthetic fabrics made from fibers (polyester, polypropylene, etc.) that are used in civil engineering and construction projects. They help with soil stabilization, drainage, filtration, and erosion control. Geotextiles can be nonwoven (felt-like texture) or woven (like a fabric with a grid pattern).

- Geocomposites: These are combinations of geotextiles and other materials, such as geomembranes, geonets, or geogrids, to enhance their functionality. They are designed for more specific applications like improved drainage, separation, or containment in landfills, highways, and water management systems. Geocomposites typically perform multiple functions simultaneously.

In short, geotextiles are simpler, while geocomposites are multi-layered systems combining geotextiles with other materials to perform more complex tasks.

What is a Geotextile Layer?

A geotextile layer is a synthetic fabric used in construction and civil engineering to enhance soil performance. It is typically installed between soil and other materials. Its main functions include:

- Separation: Prevents mixing of different soil layers, such as subgrade and aggregate in roads.

- Filtration: Allows water to pass while retaining soil particles, helping maintain soil stability.

- Drainage: Facilitates the movement of water away from soil layers, reducing water pressure.

- Reinforcement: Increases soil strength and stability, supporting heavy loads.

- Protection: Guards other materials like geomembranes from damage during installation or use.

There are two main types: woven geotextiles for strength and reinforcement, and nonwoven geotextiles for filtration and drainage.

The geocomposite layer represents a significant leap forward in the field of civil engineering and environmental management, offering a versatile and efficient solution to complex challenges. By understanding the distinct roles and benefits of geocomposites and their differences from geotextiles, professionals can better leverage these materials to enhance the sustainability, safety, and longevity of infrastructure projects. As we continue to explore and integrate these advanced materials, the potential for innovation in construction and environmental protection seems boundless, paving the way for a more resilient and sustainable future.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)