+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geocomposite membranes are a vital component in various engineering projects, offering multiple functions and benefits. In this article, we will explore what geocomposite membranes are, their functions, and their significance in construction and environmental projects.

What is a Geocomposite Membrane?

A Geocomposite Membrane is an advanced material used in various engineering and construction projects. Here is a detailed explanation:

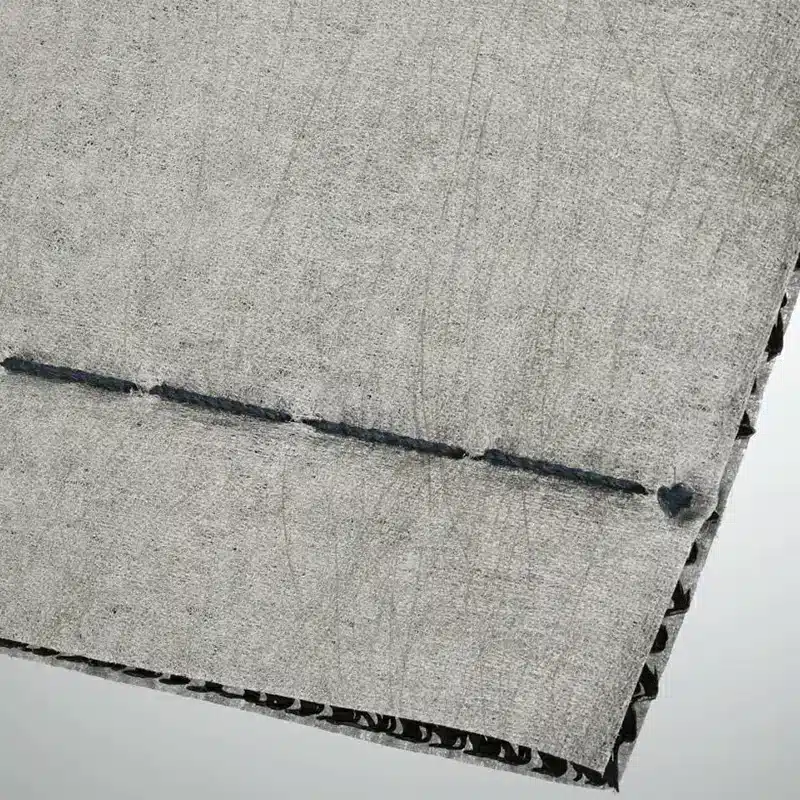

A Geocomposite Membrane is composed of a combination of different geosynthetic materials. Typically, these include:

- Geotextiles: Non-woven or woven fabrics that provide filtration, separation, and protection.

- Geomembranes: Impermeable membranes made from materials like high-density polyethylene (HDPE) or polyvinyl chloride (PVC), providing a barrier against liquids or gases.

- Geogrids: Grid-like structures that offer reinforcement.

- Geonets: Net-like materials that facilitate drainage.

The primary purposes of Geocomposite Membranes are:

- Separation: Prevents the mixing of different soil layers, maintaining the integrity of the structure.

- Reinforcement: Enhances the load-bearing capacity of the soil.

- Filtration: Allows water to pass through while retaining soil particles.

- Drainage: Facilitates the movement of water within the soil to prevent waterlogging.

- Containment: Acts as a barrier to prevent the leakage of liquids or gases.

Geocomposite Membranes are used in a wide range of applications, including:

- Landfills: For lining and capping systems to prevent contamination of surrounding areas.

- Road Construction: To reinforce roads, prevent soil mixing, and improve drainage.

- Waterproofing: In tunnels, basements, and retaining walls to prevent water ingress.

- Erosion Control: On slopes and embankments to prevent soil erosion.

- Environmental Protection: In ponds, reservoirs, and canals to prevent leakage and contamination.

Geocomposite Membranes are essential in modern construction and civil engineering, providing solutions that enhance the longevity and performance of various infrastructure projects.

What is the Function of Geocomposite?

Geocomposites serve several functions in civil engineering and construction projects, primarily focusing on enhancing drainage, filtration, and reinforcement capabilities. Here are some key functions of geocomposites:

- Drainage: Geocomposites are used to manage water flow by providing channels for water to move away from structures or areas prone to water accumulation. This helps in maintaining soil stability and preventing erosion.

- Filtration: They act as filters to prevent soil particles from clogging drainage systems while allowing water to pass through freely. This filtration function is crucial in maintaining the effectiveness and longevity of drainage systems.

- Separation: Geocomposites are used to separate different layers of soil, aggregates, or other materials with varying properties. This prevents mixing and maintains the integrity and performance of each layer.

- Reinforcement: In certain applications, geocomposites reinforce the soil or other materials, providing additional strength and stability. This reinforcement is beneficial in applications such as retaining walls, embankments, and slope stabilization.

- Protection: They offer protection to underlying materials or structures from mechanical damage during construction or from environmental factors over time. This can extend the lifespan of the overall construction.

- Environmental Benefits: Geocomposites can also have environmental benefits by reducing the need for excavation and disposal of soil, minimizing environmental impact during construction, and improving the efficiency of drainage systems.

Overall, geocomposites play a crucial role in modern construction practices, enhancing the performance and sustainability of infrastructure projects.

How are Geocomposite Membranes Used in Practice?

Introduction to Geocomposite Membranes:

Geocomposite membranes are engineered materials combining geotextiles, geonets, geomembranes, or other geosynthetic products to enhance specific properties such as filtration, drainage, protection, and reinforcement.

Practical Applications:

Landfills:

- Function: Act as liners and covers to prevent leachate from contaminating groundwater.

- Example: Municipal solid waste landfills use geocomposite membranes to contain waste and manage landfill gas emissions.

- Benefits: Improved containment and reduced environmental impact.

Mining:

- Function: Used for lining tailings ponds and heap leach pads to prevent toxic substance leakage.

- Example: Gold and copper mines employ geocomposite liners for effective containment.

- Benefits: Enhanced environmental protection and operational efficiency.

Road Construction:

- Function: Provide drainage and separation layers to enhance road durability.

- Example: Geocomposites are used in highway and railway construction projects.

- Benefits: Improved road stability and reduced maintenance costs.

Water Management:

- Function: Used in reservoirs, canals, and irrigation systems to prevent water loss.

- Example: Agricultural irrigation projects utilize geocomposite membranes for efficient water management.

- Benefits: Increased water conservation and system longevity.

Erosion Control:

- Function: Stabilize soil and prevent erosion on slopes and embankments.

- Example: Coastal and riverbank protection projects employ geocomposites.

- Benefits: Enhanced structural integrity and environmental protection.

Benefits of Geocomposite Membranes:

- Performance: Provide superior filtration, drainage, and containment capabilities.

- Durability: Resistant to chemicals, UV degradation, and physical damage.

- Cost-Effectiveness: Reduce construction and maintenance costs through improved performance.

Geocomposite membranes are versatile materials crucial in various industries for environmental protection, infrastructure development, and resource management. Their unique properties make them indispensable in enhancing the performance and durability of numerous projects.

What Should You Consider When Choosing a Geocomposite Membrane?

When choosing a geocomposite membrane, several key factors must be considered to ensure optimal performance and suitability for the specific project or application. Below is a detailed analysis of these considerations:

Project Requirements

- Purpose: Determine the primary function of the geocomposite membrane, such as drainage, filtration, separation, or reinforcement.

- Environmental Conditions: Consider the environmental factors like temperature extremes, chemical exposure, and biological activity.

Material Properties

- Durability: Assess the membrane’s resistance to puncture, tear, and UV radiation.

- Chemical Compatibility: Ensure the membrane is resistant to chemicals it will encounter in the environment.

- Permeability: Evaluate the membrane’s ability to allow or restrict fluid flow, based on the project’s needs.

Installation Considerations

- Ease of Installation: Look for materials that are easy to handle and install, reducing labor time and cost.

- Seaming and Joining Methods: Consider the methods available for joining sections of the membrane and ensure they are appropriate for the project.

Cost

- Budget Constraints: Balance the project’s budget with the cost of the membrane, considering both initial and long-term expenses.

- Lifecycle Costs: Evaluate the overall cost over the membrane’s lifespan, including maintenance and potential replacement costs.

Performance Testing and Certification

- Quality Assurance: Check for performance testing and certifications from reputable organizations to ensure reliability and performance standards.

- Case Studies and References: Review case studies and seek references from previous projects using the same membrane type.

Regulatory Compliance

- Local Regulations: Ensure the selected membrane complies with local, regional, and national regulations and standards.

Manufacturer Support

- Technical Support: Look for manufacturers that offer technical support and guidance throughout the project.

- Warranty: Consider the warranty offered by the manufacturer, which can provide added security and confidence in the product.

By thoroughly evaluating these factors, you can select a geocomposite membrane that best meets the specific needs and constraints of your project.

In conclusion, geocomposite membranes are invaluable tools in modern engineering, offering a wide range of functions that contribute to the longevity and sustainability of various projects. Their versatility, combined with their environmental benefits, makes them an essential component in today’s construction and environmental protection efforts.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)