+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

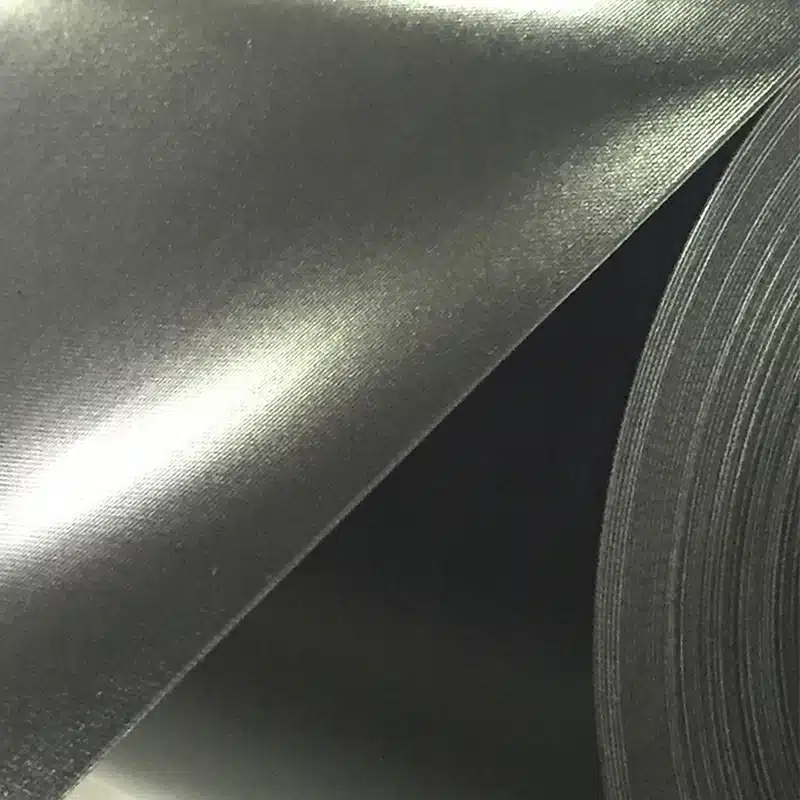

In the realm of environmental engineering and construction, geomembrane sealing systems have emerged as a cornerstone technology for containment and waterproofing solutions. These innovative barriers are designed to tackle a myriad of challenges, from preserving freshwater resources to managing hazardous waste. This article delves into the intricacies of geomembrane systems, exploring their types, uses, waterproofing capabilities, and installation techniques, shedding light on their significance and versatility in modern engineering projects.

What are the three types of geomembranes?

Geomembranes come in various materials, each with unique properties tailored to specific applications. The three primary types are:

- High-Density Polyethylene (HDPE): Renowned for its high strength and chemical resistance, HDPE geomembranes are ideal for applications requiring durability and longevity, such as landfill liners and hazardous waste containment.

- Ethylene Propylene Diene Monomer (EPDM): EPDM geomembranes stand out for their exceptional elasticity and durability, making them perfect for projects that demand resilience and environmental resistance, like decorative ponds and various roofing applications.

- Polyvinyl Chloride-Polyester (PVC-P): PVC-P geomembranes offer a balance between flexibility and strength, with excellent puncture resistance. They are commonly used in water reservoirs, aquaculture ponds, and for secondary containment of chemicals, providing a robust solution for a wide range of sealing needs.

What is a geomembrane used for?

Geomembranes serve a broad spectrum of applications across various industries, primarily focusing on containment to prevent contamination of the environment or water sources. Key uses include:

- Environmental Protection: Utilized to stabilize the earth and to secure landfills ensuring containment of hazardous or municipal wastes and their leachates, geomembranes prevent leachate from contaminating groundwater.

- Water Conservation: Liners in canals, reservoirs, and ponds are employed to prevent water loss through seepage, playing a crucial role in conserving water resources.

- Agricultural Applications: Providing liners for irrigation and aquaculture ponds to ensure water availability and quality, geomembranes support sustainable agricultural practices.

- Mining Operations: Geomembranes offer containment solutions for heap leach pads and tailings ponds to capture precious metals and prevent environmental contamination, highlighting their importance in the mining sector.

- Construction Projects: In construction, geomembranes are used for waterproofing underground structures, tunnels, and foundations to protect against water ingress, ensuring the integrity and longevity of infrastructure.

Is geomembrane waterproof?

Yes, “A geomembrane is waterproof” is a factual statement, as geomembranes are inherently designed to provide an impermeable barrier against fluid migration. Their waterproofing effectiveness is attributed to the high-quality polymers used in their manufacture, which ensures minimal water permeability. This characteristic makes geomembranes an ideal choice for applications requiring strict moisture control, such as in water reservoirs, waste containment systems, and construction waterproofing.

How do you seal a geomembrane?

Sealing a geomembrane is a critical step in ensuring its effectiveness as a barrier. The sealing process typically involves:

- Thermal Fusion: For thermoplastic materials like HDPE and LDPE, panels can be welded together using heat to create a continuous, impermeable barrier.

- Chemical Welding: PVC geomembranes often require chemical welding agents to bond the sheets, utilizing solvents that soften the material, allowing it to fuse as it dries.

- Extrusion Welding: A method used for repairs or complex joins, where a bead of molten polymer is extruded along the seam to bond the geomembrane sheets.

- Mechanical Fastening: In some cases, especially for temporary installations, geomembranes can be mechanically fastened to structures using wood, aluminum, or stainless-steel batten, though this method may not provide a completely watertight seal without additional sealing measures like tapes or sealants.

Geomembrane sealing systems stand at the forefront of environmental engineering, offering robust solutions for waterproofing and containment across a multitude of applications. From the durable HDPE to the flexible LDPE and the versatile PVC, the variety of geomembrane materials caters to diverse project requirements. These systems not only play a pivotal role in environmental protection and water conservation but also in the efficient management of agricultural, mining, and construction projects. Their waterproof nature and specialized sealing techniques ensure that geomembranes provide a reliable, impermeable barrier against liquid migration, safeguarding our natural and built environments against contamination and water loss. As technology advances, the application and effectiveness of geomembrane sealing systems are set to expand, further solidifying their importance in modern engineering solutions.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)