+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In the realm of environmental engineering and construction, the use of geomembranes, particularly those made from High-Density Polyethylene (HDPE), has become a cornerstone for projects requiring impermeable barriers. This article delves into the world of HDPE geomembranes, exploring their definition, standards, and differences from other materials like LLDPE geomembranes. Join us as we unfold the layers of this fascinating material, providing insights into its applications, benefits, and technical specifications.

What is an HDPE Geomembrane?

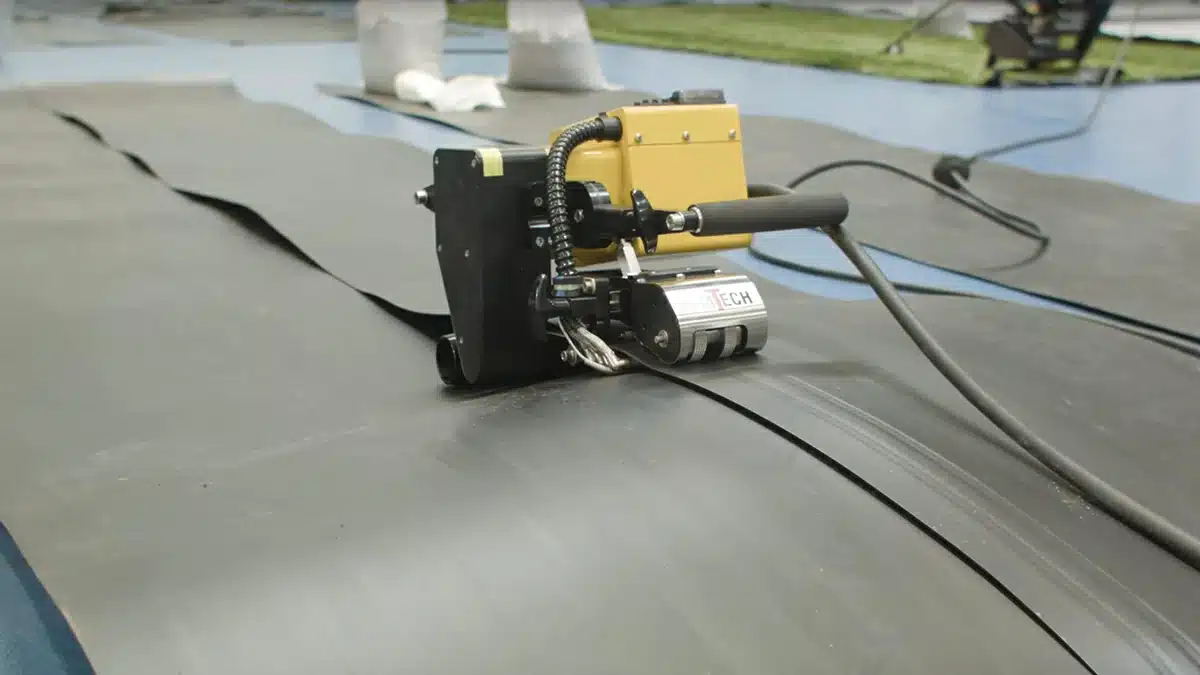

HDPE geomembrane is a type of plastic liner or barrier system that is widely used in various applications to contain liquids or prevent harmful substances from entering the soil, groundwater, or other sensitive environments. Made from high-density polyethylene, these geomembranes are not only known for their exceptional durability, chemical resistance, and impermeability but are also robust and able to withstand higher temperatures to extend the service life of your geomembrane. They are commonly used in landfill liners, pond liners, water containment projects, and mining operations, offering a reliable solution for environmental protection and water conservation.

What is the Standard of HDPE Geomembrane?

The quality and performance of HDPE geomembranes are governed by international standards, including ASTM D1505 or ASTM D792, to ensure they meet specific requirements for safety, durability, and environmental protection. One of the primary standards for HDPE geomembrane is the GRI-GM13 specification, developed by the Geosynthetic Institute (GSI). This standard, alongside ASTM D1505 or ASTM D792, outlines the physical, mechanical, and chemical properties that HDPE geomembranes must possess, such as thickness, density (as determined by ASTM D1505 or ASTM D792), tensile strength, puncture resistance, and chemical resistance. Adherence to these comprehensive standards guarantees that the geomembrane performs effectively in its intended application, providing a secure and long-lasting barrier.

What is the Difference Between HDPE and LLDPE Geomembrane?

While both HDPE and Linear Low-Density Polyethylene (LLDPE) geomembranes serve the purpose of creating effective barriers, they differ in their material properties and applications. HDPE geomembranes, known for their high rigidity and exceptional chemical resistance, are also recognized as semi-crystalline polymers with a crystallinity of about 50%, making them suitable for applications where high strength and durability are paramount. On the other hand, LLDPE geomembranes, while also chemically resistant and benefiting from their flexibility and elongation at break, make them more suitable for applications requiring the geomembrane to conform to irregular shapes or surfaces. The choice between HDPE and LLDPE geomembranes ultimately depends on the specific requirements of the project, including the nature of the substances being contained and the environmental conditions of the site.

How Do HDPE Geomembranes Support Infrastructure Development?

HDPE geomembranes play a pivotal role in supporting infrastructure development. They are crucial in the construction of roads, bridges, and tunnels, where water barrier systems are needed to protect foundational elements from moisture and erosion. In the realm of civil engineering, HDPE geomembranes are used to stabilize and secure embankments and man-made lakes, ensuring the longevity and durability of these structures. Their ability to form impermeable barriers also makes them invaluable in hydraulic fracturing operations and the creation of secondary containment systems for petrochemical plants, highlighting their contribution to the safety and efficiency of industrial processes.

HDPE geomembranes serve as a versatile solution in a wide array of industrial and infrastructure development applications. Adhering to rigorous standards like GRI-GM13, and HDPE geomembranes assure performance and reliability in critical containment tasks. The choice between HDPE and LLDPE geomembranes is dictated by the project demands, with HDPE being preferred for its strength and chemical resistance. The significant role of HDPE geomembranes in infrastructure development underscores their importance in modern engineering, offering innovative solutions to complex challenges in construction and industrial operations. By leveraging the unique properties of HDPE geomembranes, industries can achieve more sustainable, durable, and efficient outcomes, paving the way for advancements in construction and environmental management.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)