+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In the realm of geotechnical engineering, the quest for innovative solutions to stabilize slopes and prevent soil erosion has led to the development of various materials and techniques. Among these, the use of geocells, particularly in velocity slope applications, has gained significant attention. This article delves into the world of geocells, exploring their maximum slope capacity, their role in slope protection, the function of geogrids in slope stability, and the feasibility of filling geocells with concrete. By understanding these aspects, we can better appreciate the versatility and effectiveness of geocells in geotechnical applications.

What is the maximum slope for geocell?

The maximum slope for geocell applications depends on several factors, including soil type, loading conditions, and geocell properties. Here are key considerations:

- Soil Type: The stability of the slope is influenced by the type of soil. Cohesive soils like clay can support steeper slopes compared to granular soils like sand.

- Geocell Properties: The height and cell size of the geocell, as well as the material it is made from (usually high-density polyethylene), affect its performance on slopes. Larger cells and taller geocells provide better reinforcement for steeper slopes.

- Slope Length and Height: The overall geometry of the slope impacts stability. Longer and higher slopes require more reinforcement.

- Loading Conditions: The expected load on the slope, including vehicular traffic, will influence the maximum slope angle. Heavier loads require gentler slopes to maintain stability.

- Installation Technique: Proper installation, including anchoring and infill material, is crucial. Poor installation can reduce the effectiveness of the geocell.

Typical Slopes:

- For slopes up to 1:1 (45 degrees): Geocells can typically support slopes up to this angle with proper design and installation.

- For slopes steeper than 45 degrees: Specialized designs and additional reinforcement, such as retaining walls or terracing, may be necessary.

What is a geocell for slope protection?

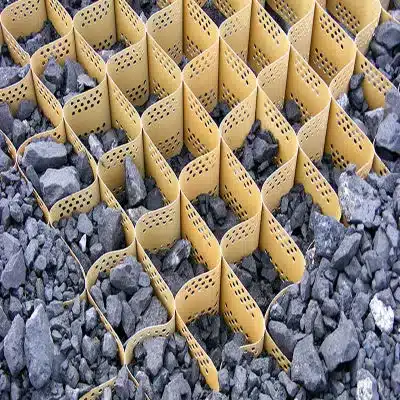

A geocell for slope protection is a three-dimensional, honeycomb-like geosynthetic structure typically made from high-density polyethylene (HDPE) or other durable polymeric materials. It is designed to stabilize and reinforce soil on slopes, embankments, and channels, effectively preventing soil erosion and surface instability. Geocells function by confining soil, aggregate, or other infill materials within their interconnected cells, creating a flexible yet semi-rigid structure that resists lateral soil movement. This confinement significantly enhances the shear strength of the soil, allowing it to withstand erosion caused by water runoff or wind. Additionally, geocells help distribute loads evenly across the slope, reducing localized stress and increasing overall slope stability. One of their key benefits is promoting vegetation growth, as the confined soil retains moisture better and provides a suitable environment for plant roots, which in turn reinforces the slope further. Compared to conventional solutions like concrete retaining walls, v are cost-effective, adaptable to irregular terrain, and environmentally friendly. Their flexibility makes them suitable for a wide range of applications, including steep slope protection, roadside embankments, and green infrastructure projects.

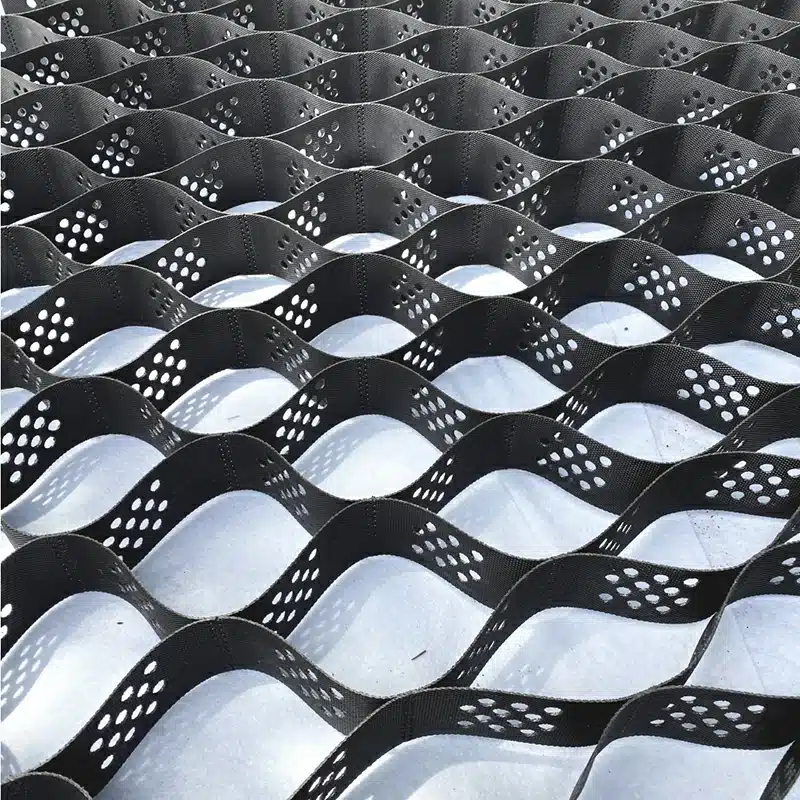

What is a geogrid for slope stability?

Sí, es posible llenar un geocell con concreto, lo cual es común en proyectos de construcción y aplicaciones de ingeniería civil que requieren alta capacidad de carga o protección adicional de taludes. El proceso se realiza siguiendo estos pasos clave:

- Preparación: Instalar y anclar correctamente el geocell, asegurando que los paneles estén unidos para formar la estructura deseada.

- Colocación: Posicionar el geocell en el área indicada, ya sea para carreteras, terraplenes, muros de contención o control de erosión.

- Selección del concreto: Elegir una mezcla adecuada en cuanto a resistencia, durabilidad y trabajabilidad, con la fluidez necesaria para un llenado uniforme.

- Llenado: Verter el concreto de manera sistemática, asegurando que todas las celdas queden completamente rellenas.

- Compactación: Usar rodillos o compactadores para eliminar burbujas de aire y lograr densidad uniforme.

- Curado: Permitir el tiempo de curado recomendado según las especificaciones de la mezcla, garantizando la resistencia y durabilidad final.

- Control de calidad: Inspeccionar durante todo el proceso para asegurar que el geocell lleno de concreto cumpla con los estándares de seguridad y diseño.

Combinando esta técnica con geogrids para refuerzo adicional, los geocells llenos de concreto ofrecen una solución versátil y resistente para la estabilización de taludes, control de erosión y diversas aplicaciones de infraestructura.

Can you fill the geocell with concrete?

Yes, geocells can be filled with concrete, which is often done in civil engineering and construction projects requiring high load-bearing capacity or enhanced slope protection. The process involves several key steps:

- Preparation: Ensure the geocell is properly installed, anchored, and interconnected to form the desired structure.

- Placement: Position the geocell in the target area, such as embankments, retaining walls, roads, or erosion-prone slopes.

- Concrete Selection: Choose a concrete mix with suitable strength, durability, and workability. A mix with adequate flow ensures even distribution within the cells.

- Filling: Pour the concrete systematically to fill each cell completely, avoiding voids.

- Compaction: Use rollers, tampers, or compactors to remove air pockets and ensure uniform density.

- Curing: Allow the concrete to cure as per the mix specifications to achieve full strength and durability.

- Quality Control: Inspect throughout the process to ensure compliance with design and safety standards.

Benefits: Concrete-filled geocells offer superior structural support, increased load-bearing capacity, and robust erosion protection. Combined with geogrids for reinforcement, they provide a versatile, long-lasting solution for steep slopes, embankments, and other demanding applications.

Geocells, with their unique three-dimensional structure, offer a versatile and effective solution for slope stabilization and erosion control. Capable of being used on slopes as steep as 70 degrees, these systems enhance the shear strength of the soil, providing robust protection against erosion and slippage. While geocells are often filled with soil or gravel, filling them with concrete is also a viable option for more demanding applications. Additionally, the use of geogrids as a complementary technology provides additional reinforcement for slope stability. Understanding the capabilities and applications of geocells and geogrids is crucial for anyone involved in geotechnical engineering and slope management.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)