+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

The weight of geotextile fabric is a crucial factor that directly impacts its performance and suitability for a wide range of civil engineering applications. Fabric weight influences the material’s strength, filtration capacity, durability, and overall functionality. Whether used in road construction, soil stabilization, drainage systems, or erosion control, selecting the right geotextile weight is vital for ensuring long-term stability and project efficiency. A clear understanding of how fabric weight and density affect performance helps engineers make informed choices, reduce risks, and optimize costs.

What Is the Density of Geotextile Fabric?

- Project application: Lightweight geotextile fabrics are best suited for drainage, landscaping, and separation applications where structural loads are low. In contrast, medium to heavyweight geotextiles are required for road construction, erosion control, slope stabilization, and soil reinforcement, where higher tensile strength and long-term stability are essential.

- Load conditions: Projects exposed to high traffic loads, heavy construction equipment, embankments, or retaining structures demand heavier geotextiles. Increased fabric weight improves tensile strength, puncture resistance, and installation survivability, allowing the material to withstand continuous mechanical stress.

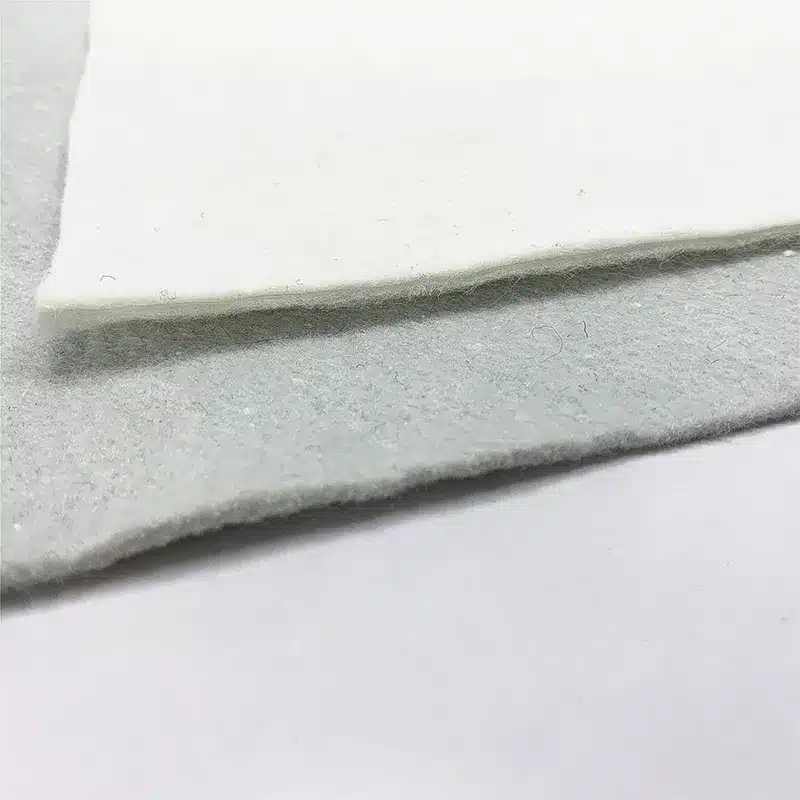

- Fabric type: Woven geotextiles are primarily selected for reinforcement due to their high tensile capacity and low elongation. Non-woven geotextiles perform best in filtration and drainage applications because of their superior permeability. Needle-punched geotextiles offer a balanced combination of strength, filtration, and drainage performance, making them suitable for multi-functional systems.

- Environmental exposure: Geotextile weight selection must consider soil gradation, groundwater flow rate, chemical exposure, UV radiation, and climatic conditions. Harsh or aggressive environments require higher-weight, more durable geotextiles to maintain performance over the design life.

What Is the Weight of Geotextile Fabric?

- Project Application Criterion: Select fabric weight based on the intended use. Lightweight geotextiles are ideal for drainage, landscaping, and separation where structural loads are low. Medium to heavyweight fabrics are necessary for road construction, erosion control, slope stabilization, and soil reinforcement, providing adequate strength and long-term stability.

- Load Condition Criterion: Consider traffic loads, construction equipment, embankments, and retaining structures. Heavier fabrics offer higher tensile strength, puncture resistance, and survivability, enabling the geotextile to withstand sustained mechanical stress.

- Fabric Type Criterion: Choose the geotextile type according to functional requirements. Woven geotextiles are preferred for reinforcement due to high tensile capacity and low elongation. Non-woven fabrics excel in filtration and drainage because of superior permeability. Needle-punched fabrics provide a balanced combination of strength, filtration, and drainage for multifunctional applications.

- Environmental Exposure Criterion: Account for soil gradation, groundwater flow, chemical exposure, UV radiation, and climatic conditions. Harsh or aggressive environments require higher-weight, more durable geotextiles to maintain performance throughout the design life.

Together, these criteria ensure the geotextile fabric weight is appropriately matched to project requirements, optimizing structural performance, stability, durability, and cost-effectiveness in civil engineering applications.

How to Choose the Right Geotextile Fabric Weight for Your Project

Selecting the appropriate geotextile fabric weight is critical to achieving optimal performance, durability, and cost efficiency. The choice should be based on a combination of structural demands, environmental conditions, and functional requirements.

- Project application: Lightweight geotextile fabrics are suitable for drainage, landscaping, and separation applications where structural loads are minimal. Medium to heavyweight geotextiles are required for road construction, erosion control, slope stabilization, and soil reinforcement, where higher tensile strength and long-term stability are essential.

- Load conditions: Projects exposed to high traffic loads, heavy construction equipment, embankments, or retaining structures demand heavier geotextiles. Increased fabric weight improves tensile strength, puncture resistance, and installation survivability, enabling the material to withstand sustained mechanical stress.

- Environmental exposure: Fabric weight selection must account for soil gradation, groundwater flow rates, chemical exposure, UV radiation, and climatic conditions. Harsh or aggressive environments require higher-weight, more durable geotextiles to maintain performance throughout the design life.

By evaluating these factors together, engineers and designers can accurately match geotextile fabric weight to project requirements, ensuring reliable structural performance, extended service life, and optimized construction costs.

Understanding geotextile fabric weight and density is essential for civil engineers and construction professionals aiming to optimize material selection and project design. Properly matching fabric weight to the intended application enhances performance, durability, and cost-effectiveness. Accurate weight calculations ensure efficient resource management and help build safer, longer-lasting infrastructure. Mastery of these concepts contributes significantly to sustainable and reliable engineering solutions worldwide.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)