+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geotextiles and geomembranes play a critical role in modern geosynthetics, supporting infrastructure development, environmental protection, and sustainable engineering worldwide. As construction standards and environmental regulations continue to evolve, these materials have become essential components in civil and environmental engineering projects.

What are geotextiles and geomembranes?

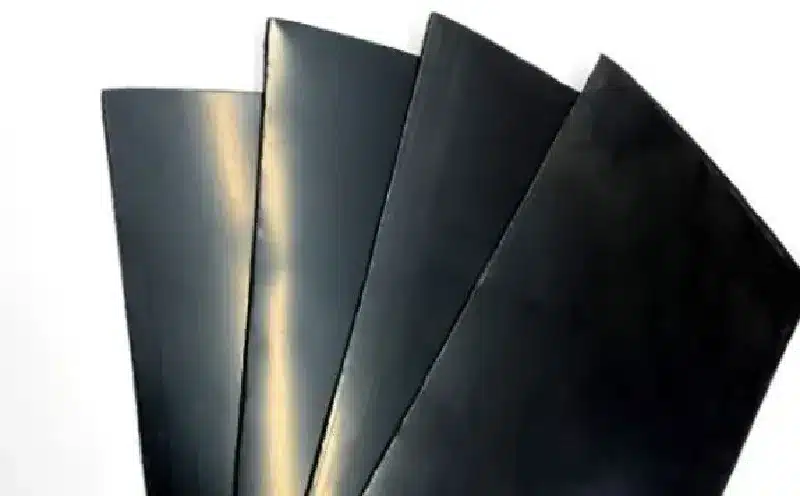

Geotextiles are permeable synthetic fabrics manufactured from polymers such as polypropylene or polyester and are widely used for separation, filtration, drainage, reinforcement, and erosion control. In practical engineering applications, materials such as high-performance geotextile fabric help improve soil stability and extend the service life of roads, embankments, and foundations. Geomembranes, by contrast, are impermeable polymer liners—commonly HDPE or PVC—designed to prevent the migration of liquids and gases. Products like HDPE geomembrane liners are widely applied in landfills, reservoirs, and mining projects to ensure reliable containment and environmental safety. In many projects, geotextiles and geomembranes are combined into integrated systems that enhance both structural performance and containment reliability.

How large is the global market for these materials?

The global geosynthetics market, which includes geotextiles and geomembranes, has experienced steady growth driven by infrastructure expansion and environmental protection projects. According to industry research, the global geosynthetics market reached approximately USD 17.6 billion in 2025 and is forecast to grow at a compound annual growth rate of about 9.5% through 2033 (Source: Grand View Research). Within this market, products supplied by professional geosynthetics manufacturers are increasingly specified for transportation infrastructure, hydraulic engineering, and environmental containment systems due to their proven performance and cost efficiency.

What industry trends are driving demand?

Large-scale investments in roads, railways, water conservancy, and urban development continue to drive demand for geosynthetics worldwide. At the same time, stricter environmental regulations are accelerating the use of geomembranes in waste management, mining, and water treatment projects. Industry analysis shows that over 60% of new landfill and mining containment projects globally now specify synthetic liner systems as standard practice (Source: Future Market Insights). As a result, engineered solutions such as composite landfill liner systems that integrate geotextiles with geomembranes are becoming the preferred choice for long-term environmental protection.

What are the practical benefits in engineering applications?

From a practical perspective, geosynthetics reduce construction costs by minimizing the need for natural aggregates and extensive earthworks. Their resistance to chemicals, UV exposure, and mechanical stress ensures long-term performance even under harsh environmental conditions. Engineering studies indicate that the use of geosynthetic reinforcement and liner systems can reduce long-term maintenance costs of roads and embankments by more than 30% (Source: U.S. Federal Highway Administration, FHWA). Infrastructure projects reinforced with solutions such as road stabilization geotextiles demonstrate improved durability, safety, and lifecycle efficiency, making them a preferred option for modern construction.

With expanding infrastructure needs and rising environmental standards, geosynthetics have become indispensable in civil and environmental engineering. By combining performance, durability, and sustainability, geotextiles and geomembranes will continue to play a central role in shaping future construction and containment systems. If needed, this article can be further optimized for website SEO with meta tags, internal linking, and image recommendations.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)