+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In the world of civil engineering and construction, HDPE geocells have become a staple for ground stabilization, erosion control, and soil reinforcement. Selecting a reliable HDPE geocell manufacturer like Geofantex is crucial for ensuring the quality and longevity of any project. This article provides an in-depth look into the requirements you should consider when choosing a manufacturer like Geofantex and answers the most common questions about HDPE geocells.

What are HDPE Geocells, and why are they important in construction?

What are HDPE Geocells?

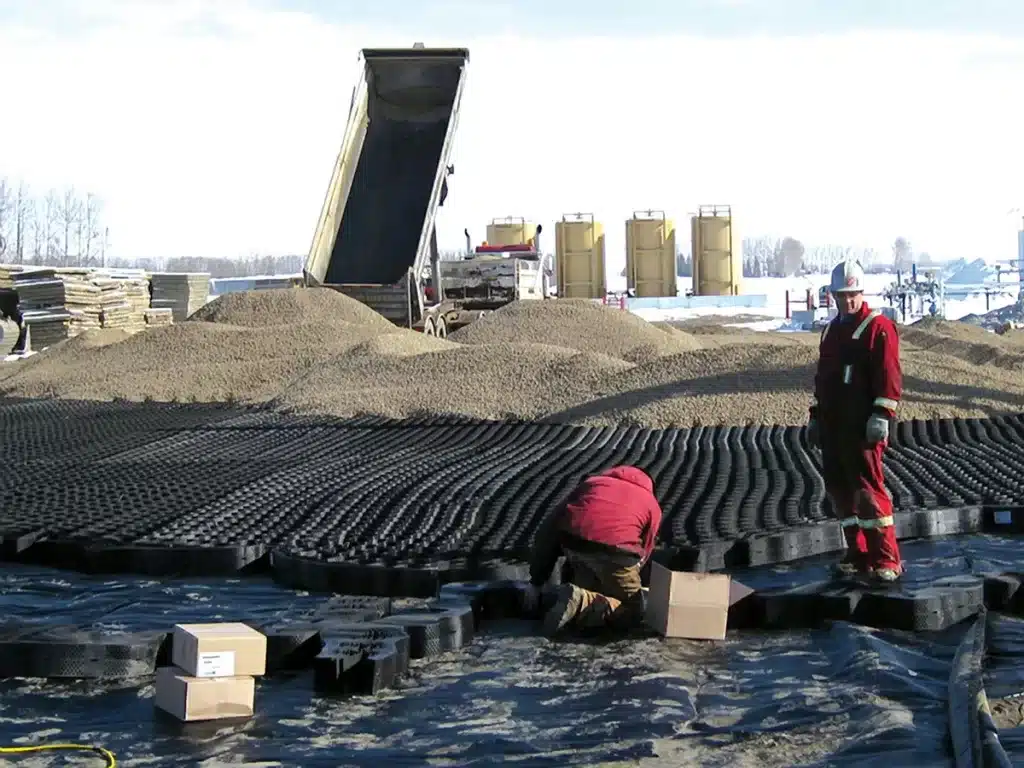

HDPE (High-Density Polyethylene) Geocells are three-dimensional, honeycomb-like structures made from strips of high-density polyethylene. These cells are expanded at the construction site to form a robust matrix that is filled with various materials such as soil, sand, or gravel. The interconnected cells function as a confinement system, stabilizing the infill material and distributing loads over a wider area.

Why are HDPE Geocells Important in Construction?

| Soil Stabilization and Erosion Control | HDPE Geocells are widely used for soil stabilization, particularly on slopes and embankments. The cellular structure confines the soil or aggregate, preventing lateral movement and reducing erosion. This is crucial in maintaining the structural integrity of slopes, preventing landslides, and ensuring long-term stability. |

| Load Distribution | When used in road construction, HDPE Geocells distribute heavy loads more evenly across the subgrade. This reduces the risk of rutting and increases the lifespan of roads, particularly in areas with weak or compressible soils. The geocells also enhance the load-bearing capacity of the foundation, making them ideal for use in construction projects requiring high load-bearing efficiency. |

| Cost-Effectiveness | By improving soil stabilization and load distribution, HDPE Geocells reduce the need for extensive earthworks and expensive foundation materials. This can result in significant cost savings, especially in large-scale projects such as highways, railways, and airport runways. |

| Environmental Benefits | HDPE Geocells contribute to environmental protection by minimizing soil erosion and reducing the need for traditional construction materials. Additionally, they can be used with locally available fill materials, further reducing the environmental impact of transportation and material extraction. |

| Versatility | HDPE Geocells are highly versatile and can be used in a wide range of construction applications, including retaining walls, channel protection, slope stabilization, and load support. Their flexibility and adaptability make them an essential tool in modern construction, capable of addressing various geotechnical challenges. |

HDPE Geocells are crucial in construction for their ability to stabilize soils, control erosion, distribute loads, and reduce costs. Their environmental benefits and versatility make them indispensable in many infrastructure projects, ensuring the longevity and sustainability of the structures they support.

How do I ensure the HDPE geocell manufacturer is reliable?

To ensure an HDPE geocell manufacturer is reliable, consider the following steps:

- Reputation: Check customer reviews, testimonials, and case studies.

- Certifications: Verify that the manufacturer meets relevant industry standards.

- Manufacturing Process: Inquire about the materials and production process to ensure they meet specifications.

- Customer Service: Assess responsiveness and willingness to assist with inquiries.

- Experience: Look for a manufacturer with a proven track record in similar projects.

- References: Request references from previous clients for insights into reliability and product performance.

By focusing on these areas, you can confidently choose a reliable manufacturer for your geocell needs.

What should I consider when comparing different HDPE geocell manufacturers?

When comparing HDPE geocell manufacturers, consider the following categories:

Product Specifications

- Material Quality: Assess the HDPE quality and UV resistance, as it affects the geocell’s lifespan and performance under exposure.

- Size and Configuration Options: Different projects may require specific cell sizes, depths, or wall thicknesses. Check if the manufacturer offers a range of configurations.

- Strength and Load Capacity: Ensure the geocells meet your project’s load-bearing requirements, which may vary for applications like slope stabilization, erosion control, or road reinforcement.

Manufacturing Standards

- Certifications and Compliance: Look for manufacturers who adhere to industry standards, such as ISO certifications or ASTM compliance, ensuring consistent quality and performance.

- Production Technology: Advanced manufacturing techniques, like ultrasonic welding, can enhance geocell strength and longevity.

Durability and Environmental Impact

- Durability: Evaluate factors like UV stability, chemical resistance, and durability under different environmental conditions.

- Eco-Friendliness: Consider manufacturers who use recycled materials or eco-friendly processes, especially for projects with sustainability goals.

Reputation and Track Record

- Industry Experience: Manufacturers with years of experience may provide better insights and proven products.

- Client Feedback and Case Studies: Research reviews and case studies to see how the product performed in similar projects.

Financial Aspects

- Cost vs. Value: Balance pricing with quality, considering long-term costs due to potential replacements or maintenance.

- Warranty and Return Policy: A robust warranty can be a sign of confidence in product quality.

Customer Support and Technical Assistance

- Technical Support: Manufacturers offering technical assistance can help with installation and troubleshooting, crucial for complex projects.

- Response Times and Availability: Quick, reliable customer support is valuable, particularly if the product is crucial for ongoing construction.

These categories will guide a comprehensive and informed evaluation, helping you select the HDPE geocell manufacturer best suited to your project’s specific demands.

Can HDPE geocells be used for both temporary and permanent applications?

Temporary Applications

HDPE geocells can be effectively used in temporary applications, such as construction sites or event setups. They provide stabilization for soils, prevent erosion, and facilitate drainage. Their lightweight and portable nature makes them ideal for short-term use.

Permanent Applications

For permanent applications, HDPE geocells are suitable for projects like retaining walls, slope stabilization, and landscaping. They enhance soil strength, reduce erosion, and promote vegetation growth. Their durability and resistance to environmental stressors contribute to their long-term effectiveness.

Examples

- Temporary: Used in a construction site to support access roads and prevent soil erosion during heavy rainfall.

- Permanent: Employed in a landscaping project for a park to create stable walking paths and retain soil on slopes.

HDPE geocells offer versatility, making them valuable in both temporary and permanent scenarios.

In conclusion, selecting the right HDPE geocell manufacturer is pivotal for ensuring the success and durability of your construction projects. By considering the outlined requirements and armed with answers to these common questions, you’ll be well-equipped to make an informed decision. Remember, the quality of your geocell system directly impacts the overall stability and longevity of your construction endeavors, so choose wisely. With its commitment to quality, customization, and customer service, Geofantex stands out as a leading choice for your HDPE geocell needs.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)