+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

High-strength geotextile fabrics are essential components in civil engineering and construction projects, offering robust reinforcement and durability in a variety of applications. These fabrics are designed to stabilize soil, prevent erosion, and enhance the lifespan of infrastructure. In this article, we’ll explore what makes geotextiles strong, the different types available, their tensile strength, and their longevity in the field.

What is the strength rating of geotextile?

Types of Geotextiles

- Woven Geotextiles: Made by weaving synthetic or natural fibers, they are known for high tensile strength and durability.

- Non-Woven Geotextiles: Manufactured using needle punching or heat bonding, they are more flexible and better suited for filtration and drainage.

- Knitted Geotextiles: Produced by interloping yarns, these are less common but offer specialized properties.

Testing Methods for Strength Ratings

- Tensile Strength Testing: Measures the maximum load a geotextile can bear before failure.

- Puncture Resistance Testing: Assesses the material’s resistance to perforation or puncture.

- CBR Push-Through Strength: Simulates stresses from sharp objects like rocks.

- Tear Resistance Testing: Determines resistance to tearing when cut.

Typical Strength Ratings

- Woven Geotextiles: Tensile strength ranges from 100 to 400 kN/m, depending on material and application.

- Non-Woven Geotextiles: Tensile strength typically ranges between 5 and 150 kN/m, optimized for filtration and separation.

- High-Performance Geotextiles: Can exceed 600 kN/m for heavy-duty applications like embankment stabilization.

Applications and Recommendations

- Road Construction: Use high-strength woven geotextiles to reinforce and separate soil layers.

- Erosion Control: Employ non-woven geotextiles for filtration and drainage.

- Waste Containment: Opt for geotextiles with high puncture resistance to protect geomembranes.

What are the three types of geotextile fabric?

Woven Geotextile Fabrics

- Description: Made by weaving fibers into a high-strength fabric, woven geotextiles are typically strong and durable. They have a grid-like appearance and are less porous compared to other types.

- Applications: Ideal for road construction and erosion control. Used in projects requiring high tensile strength, such as retaining walls and embankments.

- Advantages: High load-bearing capacity. Excellent for soil stabilization.

- Disadvantages: Limited permeability, making them less suitable for drainage.

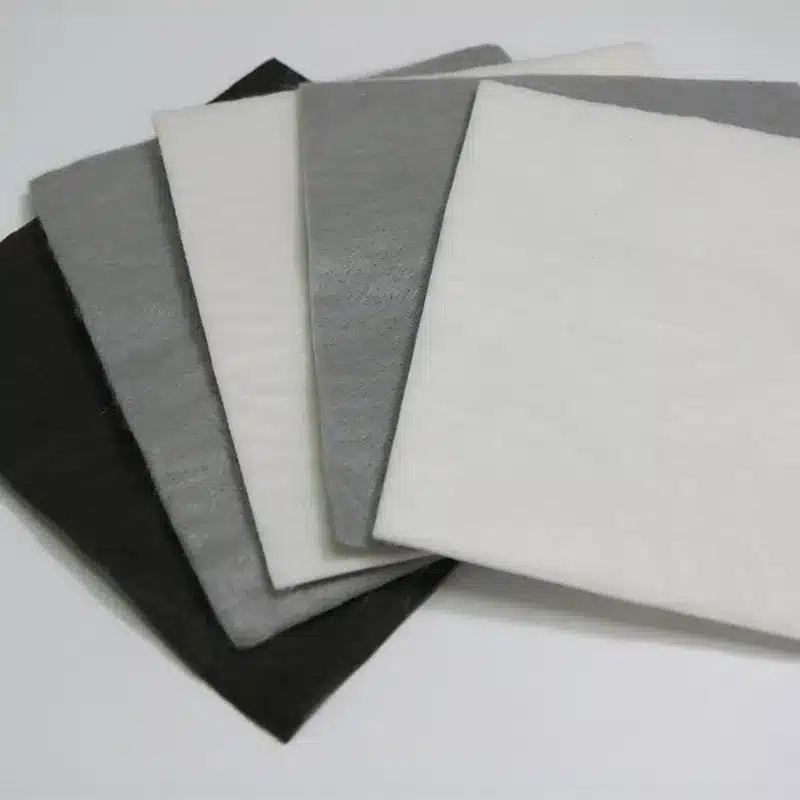

Non-Woven Geotextile Fabrics

- Description: Made by bonding fibers together through heat, needle punching, or chemical bonding, non-woven geotextiles resemble felt. They are highly porous and are excellent for filtration.

- Applications: Commonly used for drainage, filtration, and separation. Effective in subsurface drainage systems and landfill liners.

- Advantages: Excellent water flow and filtration properties. Flexible and easy to install.

- Disadvantages: Lower tensile strength compared to woven fabrics. Susceptible to damage under heavy loads.

Knitted Geotextile Fabrics

- Description: Created by interlooping yarns, knitted geotextiles are a blend of woven and non-woven characteristics. They are less common but are used for specific applications requiring unique flexibility and strength combinations.

- Applications: Used in specific environmental engineering tasks, such as slope reinforcement and specialized filtration.

- Advantages: Combines flexibility with moderate strength. Adaptable to complex geometries.

- Disadvantages: Limited availability and higher cost. Not as durable as woven fabrics for heavy loads.

What is the tensile strength of geotextiles?

The tensile strength of geotextiles refers to the maximum amount of stress the fabric can withstand before it breaks. High strength geotextiles can have tensile strengths ranging from 200 to over 800 pounds per square inch (psi), with some specific applications requiring strengths as precise as 160 pounds per inch. The specific tensile strength needed depends on the application; for instance, road construction projects may require higher tensile strength to support heavy loads and prevent soil displacement.

Does geotextile fabric break down?

The tensile strength of geotextiles refers to the maximum amount of stress the fabric can withstand before it breaks. High strength geotextiles can have tensile strengths ranging from 200 to over 800 pounds per square inch (psi), with some specific applications requiring strengths as precise as 160 pounds per inch. The specific tensile strength needed depends on the application; for instance, road construction projects may require higher tensile strength to support heavy loads and prevent soil displacement. The non-woven geotextile usually breaks down quicker than woven geotextiles, which is an important consideration when choosing the right material for long-term applications.

High strength geotextiles are critical for ensuring the stability and longevity of various construction and civil engineering projects. With tensile strengths that can exceed 800 psi, these fabrics are built to withstand significant stress while maintaining their structural integrity. Understanding the different types of geotextile fabrics and their specific applications allows engineers to select the right material for each project. While geotextile fabric is durable, its longevity can be influenced by environmental factors, so proper installation and protection are key to maximizing its effectiveness over time.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)