+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geotextiles, a vital component in construction and landscaping, are widely used for soil stabilization, drainage, and erosion control. Proper geotextile installation ensures these benefits are maximized, making structures more durable and environmentally friendly. This article covers essential questions and answers about geotextile installation, highlighting its benefits, processes, and considerations.

What is the purpose of installing geotextile fabric?

Geotextile fabric is installed to enhance soil stability, manage water flow, and protect against erosion. Its main purposes include:

- Soil stabilization: Strengthens weak or loose soils, providing a solid foundation for roads, patios, embankments, and landscaping projects.

- Erosion control: Prevents soil displacement caused by wind, rain, or water runoff, helping maintain slopes, embankments, and coastal areas.

- Drainage improvement: Acts as a filter layer that allows water to pass while keeping soil particles separate, ensuring efficient drainage and reducing waterlogging.

- Weed suppression: Blocks weed growth in landscaping applications, reducing maintenance needs.

- Structural longevity: Enhances the durability of construction projects by reducing soil movement, improving load distribution, and extending the lifespan of infrastructure.

By installing geotextile fabric, builders and landscapers create more durable, stable, and environmentally resilient projects.

What Are the Key Steps in Geotextile Installation?

- Site preparation: Clear the area of vegetation, debris, sharp objects, and soft spots that could damage the fabric. Level and compact the subgrade to create a stable, uniform surface.

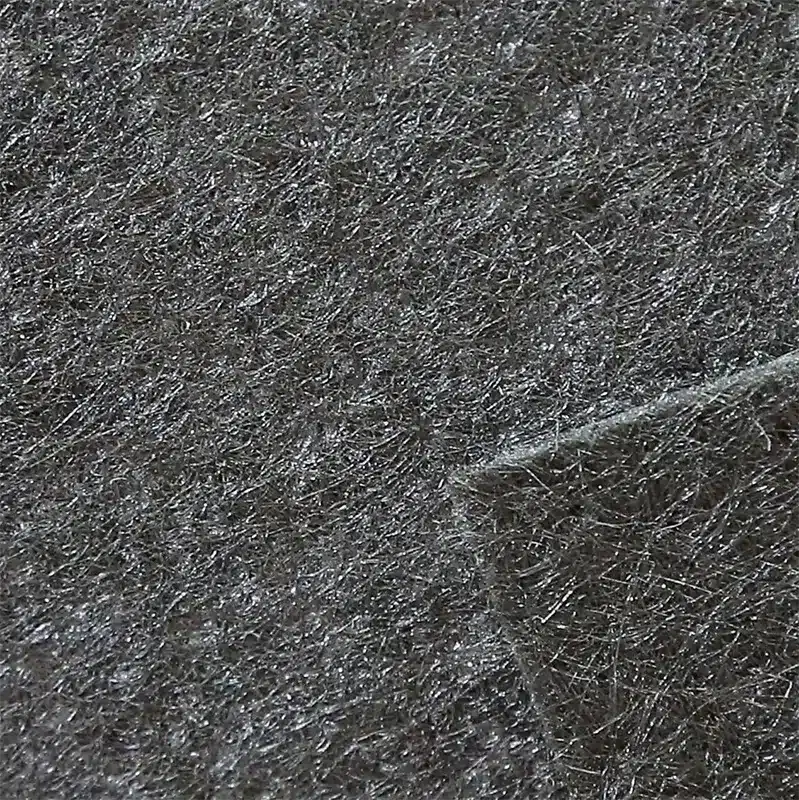

- Geotextile selection: Choose the appropriate woven or non-woven geotextile based on the required function—separation, filtration, drainage, reinforcement, or erosion control.

- Layout and alignment: Plan the layout direction according to load or water flow requirements. Unroll the geotextile smoothly over the prepared surface, keeping it flat and tensioned to avoid wrinkles or folds.

- Overlapping and seaming: Overlap adjacent sheets by 30–60 cm (12–24 inches) or as specified by design standards. Where higher strength is needed, use sewing, heat bonding, or mechanical fastening.

- Anchoring and securing: Secure the geotextile with pins, staples, sandbags, or anchor trenches to prevent movement during backfilling and construction activities.

- Cover placement: Place soil, gravel, or aggregate gently over the fabric to avoid tearing or displacement. Do not drive equipment directly on exposed geotextile unless specifically allowed.

- Inspection and repair: Inspect the installed fabric for damage, misalignment, or exposure. Repair any tears or gaps before proceeding with the next construction layer.

Following these steps ensures the geotextile performs effectively, providing long-term soil stability, drainage efficiency, and structural protection in construction and landscaping projects.

How Does Geotextile Fabric Improve Drainage Performance?

Geotextile fabric plays a critical role in drainage systems by functioning as a permeable separation and filtration layer. It allows water to pass freely while preventing soil particles from migrating into drainage media, thereby maintaining system efficiency over time. Key drainage-related benefits include:

- Efficient filtration: Geotextiles permit continuous water flow while retaining fine soil particles, preventing clogging of gravel layers, perforated pipes, and drainage channels.

- Erosion control: By regulating water movement and reducing soil displacement, geotextiles help preserve slopes, embankments, and landscaped areas, especially under heavy rainfall conditions.

- Reduced waterlogging: Properly installed geotextiles guide subsurface water away from foundations and load-bearing layers, lowering the risk of saturation-related damage.

- Extended drainage system lifespan: Limiting sediment intrusion reduces maintenance requirements and preserves the hydraulic capacity of systems such as French drains, retaining wall backdrains, and roadway subdrainage.

- Wide applicability: Geotextile drainage solutions are commonly used in highways, retaining walls, landfills, coastal protection works, and residential landscaping, where reliable water management is essential.

Overall, geotextile fabric provides a durable, low-maintenance approach to drainage control, ensuring long-term performance while protecting soil structure in both civil engineering and landscaping projects.

How can proper geotextile installation extend the lifespan of construction and landscaping projects?

- Soil reinforcement: Stabilizes weak soils and distributes loads evenly, reducing settlement and structural damage.

- Erosion control: Protects slopes, embankments, and landscaped areas from wind and water erosion, maintaining design integrity.

- Efficient drainage: Prevents waterlogging and sediment buildup in drainage layers, ensuring long-term hydraulic performance.

- Reduced maintenance: Minimizes soil movement and surface degradation, lowering repair frequency and costs.

- Sustainable construction: Supports environmentally resilient projects by preserving soil and managing water effectively.

Geotextile installation is a straightforward yet crucial step in many construction and landscaping projects. By properly selecting and installing geotextile fabric, you can enhance soil stability, improve drainage, and extend the lifespan of structures. Whether for heavy-load areas or residential landscaping, geotextiles offer a sustainable solution for ground reinforcement, making them invaluable in modern construction.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)