+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

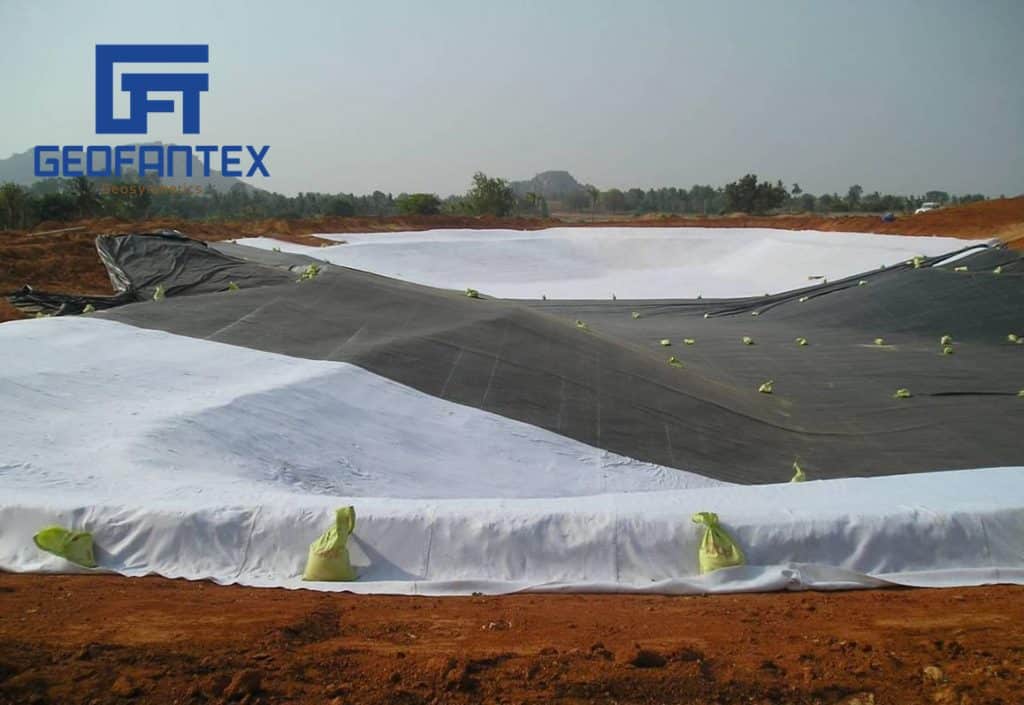

Geotextile installation ensures long-term soil reinforcement, drainage, filtration, and separation performance. Before purchase, verify material specifications, inspect the site, and plan proper handling, laying, and backfilling to guarantee durability and project effectiveness.

What Are the Key Steps for Proper Geotextile Installation?

Proper geotextile installation is essential to ensure long-term performance in soil stabilization, drainage, filtration, and reinforcement applications. A strict, step-by-step approach should be followed, including:

- Pre-installation preparation:Inspect subgrade conditions, remove sharp objects, level the surface, and verify material specifications before installation.

- Correct transportation and storage: Handle rolls carefully, avoid dragging or dropping, protect from UV exposure and moisture, and store on clean, raised surfaces.

- Careful geotextile laying: Lay the fabric flat without wrinkles, ensure correct alignment, maintain specified overlaps, and avoid tension or stretching.

- Controlled backfilling and covering: Place backfill materials gradually and evenly to prevent puncture or displacement, and cover the geotextile immediately to protect it from UV damage.

- Proper compaction practices: Compact backfill in layers according to project specifications, avoiding excessive direct pressure on the geotextile.

- Quality control and inspection: Check for tears, seam integrity, alignment, and conformance with design requirements before and after covering.

- Ongoing maintenance and monitoring: Conduct regular inspections to verify drainage performance, structural stability, and long-term material integrity.

Following these key installation steps minimizes failure risks and ensures that geotextiles perform as designed throughout their service life.

Backfilling and Covering: Protecting and Enhancing Geotextile Performance

After proper installation, the geotextile fabric must be carefully backfilled and covered with specified materials to ensure long-term protection and optimal performance. Key considerations include:

- Backfill Material Selection: Use approved materials such as gravel, crushed stone, sand, or soil that comply with project specifications. Material choice should match the geotextile’s intended function—drainage, separation, filtration, or reinforcement.

- Controlled Backfilling: Place backfill gradually and evenly over the geotextile. Spread materials in layers to reduce the risk of punctures, tearing, or fabric displacement during placement.

- Compaction Practices: When compaction is required, follow engineering standards and project guidelines. Avoid excessive or direct compaction loads on the geotextile to prevent deformation or rupture.

- UV Protection: Cover the geotextile immediately after placement. Prompt covering prevents UV exposure, which can degrade synthetic fibers if left uncovered for extended periods.

- Drainage Performance: Proper backfilling maintains effective water flow through and around the geotextile, supporting long-term drainage and filtration efficiency.

By applying strict backfilling and covering procedures, the geotextile’s integrity and service life are preserved, improving soil stability, erosion control, and structural reinforcement in the completed project.

Backfilling or Covering

- Covering Layer: After installation, the geotextile should be immediately covered with the intended backfill material, such as soil, aggregate, or gravel. This step is crucial for protecting the material from UV degradation and mechanical damage.

- Controlled Backfilling: Backfill material should be placed carefully over the geotextile to avoid damage during compaction. The compaction process should be done in layers, avoiding excessive compaction directly on the geotextile.

- Compaction: If required by the project, backfill should be compacted according to the project specifications. Excessive compaction should be avoided to minimize stress on the geotextile.

Quality Control and Inspection

- Post-Installation Inspection: Regularly inspect the geotextile for any tears, wrinkles, or improperly aligned sections. Ensure that all seams are intact and overlaps are correctly placed.

- Conformance with Design Specifications: Verify that the material and installation process meet the specifications outlined in the project design, including strength, permeability, and thickness.

- Testing: If required, perform tests on the geotextile to verify its properties, including tensile strength, elongation, and permeability.

Safety and Environmental Considerations

- Safety Measures: Ensure that all workers are aware of the handling, storage, and installation procedures to minimize risks. Use appropriate protective gear when handling geotextile rolls.

- Environmental Protection: Avoid exposing geotextile materials to harsh weather conditions, UV light, or excessive moisture. Install it promptly after unrolling to minimize exposure time.

Maintenance and Monitoring

To ensure geotextiles perform optimally throughout their service life, a systematic maintenance and monitoring program is essential:

- Regular inspection: Check the installed geotextile for tears, wrinkles, misalignment, or damaged seams and overlaps.

- Drainage and filtration verification: Ensure water flows correctly through and around the geotextile, maintaining its intended drainage and filtration functions.

- Structural evaluation: Confirm that the material continues to support loads and reinforce the soil according to project specifications.

- Ongoing environmental protection: Keep exposed areas covered and avoid prolonged UV, excessive moisture, or chemical exposure that could degrade the material.

- Documentation and tracking: Record all inspections and maintenance activities to ensure traceability and support informed decisions for any interventions.

Implementing these measures minimizes long-term failure risks, guarantees project stability, and maximizes the geotextile’s functional performance in reinforcement, separation, filtration, and drainage applications.

This method ensures the proper performance of geotextiles and guarantees their effectiveness in reinforcing, draining, or separating materials as per the design criteria. Each step is critical to prevent any long-term issues that may arise from improper installation.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)