+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Slow down reflection cracks

To effectively slow down or minimize reflection cracks and prevent further damage or deterioration, follow these steps:

- Identify the Cause: Determine if the cracks are caused by underlying issues such as structural movements, thermal expansion, or material fatigue.

- Surface Preparation: Clean the surface thoroughly to remove debris, dust, and any loose materials. Ensure the surface is dry before applying any treatments.

- Crack Filling: Use appropriate crack fillers designed for the specific material (e.g., asphalt, concrete). Ensure the filler is flexible to accommodate any future movements.

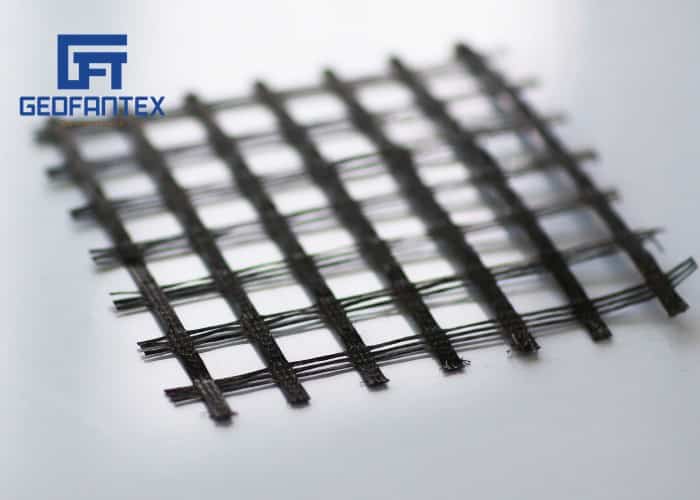

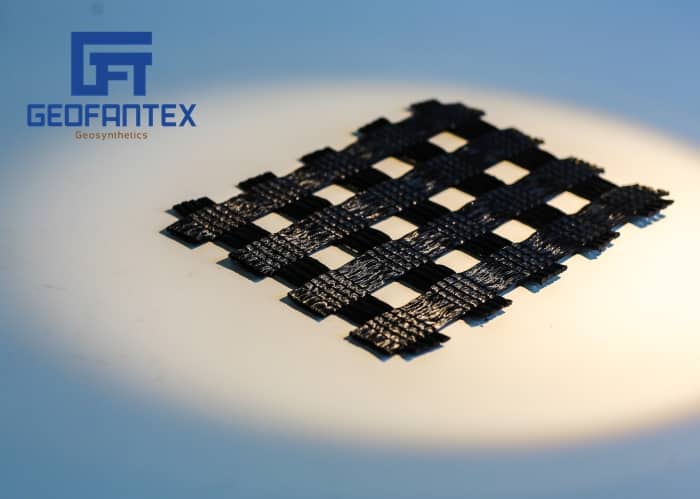

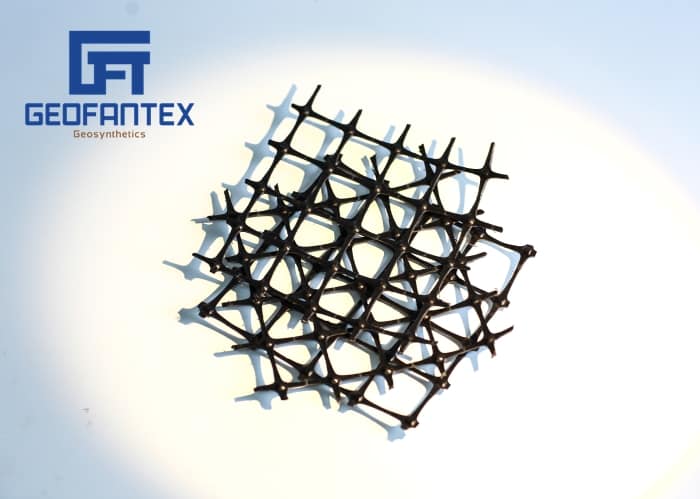

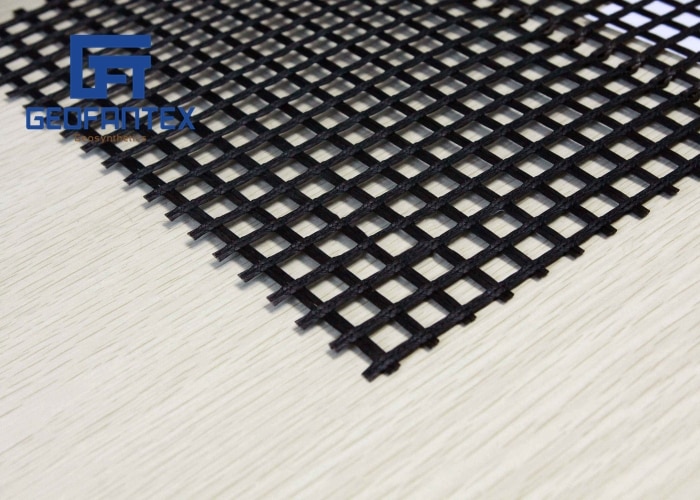

- Reinforcement: Apply a reinforcement layer such as geotextiles or fiberglass mats over the affected area to distribute stress and prevent further cracking. Secure the reinforcement properly to ensure it remains in place.

- Seal Coating: Apply a high-quality seal coat to protect the surface from water infiltration, UV rays, and chemical damage. Ensure even application and adequate drying time.

- Regular Maintenance: Conduct regular inspections and maintenance to identify and address new cracks early. Reapply seal coats and fillers as needed to maintain the integrity of the surface.

Anti-fatigue cracking

| Repeated Stress | Anti-fatigue cracking occurs due to the repeated application of stress or loads on a material, typically metal, over an extended period. |

| Microstructural Defects | Existing microstructural defects, such as voids or inclusions, can initiate cracks when subjected to cyclic stress. |

| Material Properties | Materials with lower fatigue strength are more susceptible to anti-fatigue cracking. |

Effects

| Structural Integrity | Cracks can compromise the structural integrity of components, leading to potential failure. |

| Safety Hazards | Such cracks pose significant safety risks in critical applications like aviation or construction. |

| Economic Impact | Repairing or replacing components affected by fatigue cracking can incur substantial costs. |

Prevention Methods

| Material Selection | Using materials with high fatigue strength can reduce the risk of anti-fatigue cracking. |

| Design Optimization | Designing components to minimize stress concentrations, such as avoiding sharp corners, can help prevent crack initiation. |

| Surface Treatments | Processes like shot peening can improve surface properties, enhancing resistance to fatigue. |

Potential Solutions

| Regular Inspections | Implementing regular inspection schedules to detect early signs of fatigue cracking. |

| Stress Reduction Techniques | Employing techniques such as stress relieving heat treatments to reduce residual stresses. |

| Repair Methods | Using methods like welding or adhesive bonding to repair cracks and restore structural integrity. |

High-temperature resistant rutting

High-temperature rutting in asphalt pavements is a common and serious problem, particularly in regions with hot climates or areas subjected to heavy traffic loads. Rutting refers to the permanent deformation of the pavement surface, typically in the wheel paths, that leads to depressions or grooves. Here’s a detailed breakdown:

Introduction to High-Temperature Rutting

High-temperature rutting occurs when asphalt mixtures soften and deform under elevated temperatures. This leads to permanent changes in the shape of the pavement, which negatively impacts ride quality and safety. Rutting is exacerbated by the accumulation of traffic load and extended exposure to high temperatures, typically above 50°C (122°F).

Causes of High-Temperature Rutting

Rutting primarily results from the balance of two factors:

- Asphalt Binder Properties: The viscosity and stiffness of the binder play a crucial role in resisting deformation. At high temperatures, if the binder becomes too soft (low viscosity), it cannot maintain its structural integrity under heavy traffic.

- Aggregate Characteristics: The type and size of aggregates used in the mix can influence how the asphalt mixture handles high temperatures. If aggregates are weak or poorly graded, they may displace under load, contributing to rutting.

- Traffic Load: Continuous heavy traffic leads to compaction of the asphalt, which, combined with high temperatures, accelerates rutting.

- Climate: In hotter climates, the temperature rise can soften the binder, making it more prone to deformation.

Effects of Rutting on Pavement Performance

- Reduced Structural Integrity: Rutting can lead to the loss of the pavement’s strength and service life, requiring more frequent repairs and maintenance.

- Safety Hazards: Ruts can collect water, creating unsafe driving conditions, particularly in rainy weather, leading to hydroplaning or loss of traction.

- Increased Maintenance Costs: As rutting becomes more severe, it can lead to deeper structural issues and higher costs for resurfacing or reconstruction.

Solutions and Preventive Measures

- Use of Modified Asphalt Binders: Polymer-modified or SBS (styrene-butadiene-styrene) binders are often used to improve the high-temperature performance by increasing the viscosity and reducing the likelihood of rutting.

- Proper Mix Design: A well-designed asphalt mixture with an appropriate balance of binder, aggregate, and additives can enhance resistance to rutting. Techniques like using stiffer binders or optimizing aggregate gradation can help.

- High-Temperature Compaction: Ensuring that asphalt is compacted at the right temperature can also reduce the potential for rutting.

- Use of Warm-Mix Asphalt (WMA): WMA technologies reduce mixing and compaction temperatures, leading to less thermal deformation and better long-term performance.

Conclusion: High-temperature rutting remains a significant challenge in asphalt pavement design, but through the use of advanced materials, better mixture design, and appropriate construction practices, it is possible to minimize the problem. With continued innovation in binder technology and pavement management, the durability of pavements under high-temperature conditions can be significantly enhanced.

Resistance to low-temperature shrinkage and cracking

Low-temperature shrinkage and cracking are common challenges for construction materials like concrete and asphalt, particularly in regions where the temperature frequently drops below freezing. These issues can compromise the durability and longevity of infrastructure, making it essential to understand the factors that influence these behaviors and the measures that can be taken to minimize them.

Chemical Composition

Concrete’s resistance to low-temperature shrinkage is primarily influenced by its water-to-cement ratio, type of cement, and aggregate characteristics. High water content can lead to more shrinkage as water evaporates during freezing and thawing cycles. The use of air-entrained concrete, which incorporates tiny bubbles into the mix, can help alleviate freeze-thaw damage by providing space for water to expand without causing cracks. In asphalt, the presence of bitumen with lower viscosity can affect its flexibility in cold temperatures. Asphalt can become brittle if the bitumen stiffens too much, leading to cracking.

Physical Properties

The strength and flexibility of both materials are key. Concrete’s compressive strength increases as it cures, but its susceptibility to cracking in freezing conditions depends on its tensile strength, which is relatively low. Asphalt’s flexibility depends on the type and amount of aggregate used, and its resistance to cracking is enhanced by the optimal mix of binder and aggregate, as well as proper compaction during placement.

Additives and Treatments

- Concrete: The use of non-chloride accelerators and waterproofing agents can reduce water migration and prevent frost damage. In addition, the incorporation of polypropylene fibers helps in improving the material’s overall toughness.

- Asphalt: Additives like warm mix asphalt (WMA) technologies can enhance the workability of asphalt at lower temperatures, reducing the chances of thermal cracking. Polymer-modified asphalts (PMA) also offer improved elasticity and resistance to low-temperature cracking.

Environmental Considerations

Environmental factors such as the rate of temperature change, humidity, and exposure to freeze-thaw cycles play a significant role in the development of shrinkage and cracking. Rapid temperature fluctuations can increase the internal stresses within the material, leading to cracking. Concrete and asphalt must be designed to withstand these stresses by using appropriate materials and mixes that are tailored to the local climate conditions. In regions with extreme winter conditions, additional protective measures may be needed during construction, such as the use of curing blankets or insulation during the initial curing period.

Recommendations for Practice

- Concrete: Ensure proper curing techniques to allow the concrete to achieve adequate strength before freezing conditions begin. Use air-entrained concrete in freeze-thaw zones to protect against moisture expansion.

- Asphalt: Use warm mix asphalt technologies to improve the workability and flexibility of the mix in cold temperatures. Ensure proper compaction during the laying of asphalt to avoid air pockets that can contribute to cracking under cold stress.

By addressing these factors in the design and application of concrete and asphalt, it is possible to significantly reduce the risk of low-temperature shrinkage and cracking, ensuring more durable infrastructure in cold-weather environments.

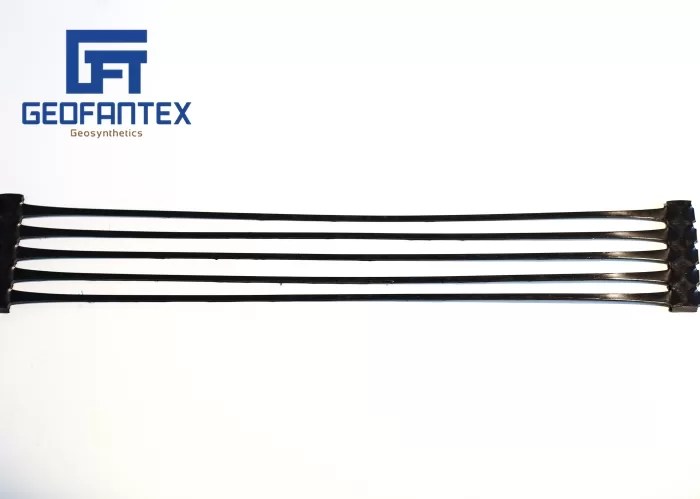

The application of fiberglass geogrid in the asphalt overlay greatly improves the tensile strength of asphalt concrete, which can resist large tensile stress without causing damage. In addition, even if cracks are generated in a local area, the stress at the place where the crack occurs is too concentrated, but it will gradually disappear through the transmission of the glass fiber geogrid, and the crack will no longer develop into a crack. When selecting the fiberglass geogrid, in addition to its performance indicators should meet the requirements in the above table, special attention should be paid to ensure that its width is not less than 1.5m so that it has a sufficient cross-sectional area when used as an interlayer to control reflection cracks. Fully dissipate the crack energy; at the same time, the mesh size should be 0.5 to 1.0 times the maximum particle size of the upper asphalt surface material, which helps to achieve the best shear adhesiveness and promote aggregate interlocking and restriction.

For more information please contact to Geofantex Geosynthetics Co., Ltd.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)