+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Understanding the Differences Between Woven and Nonwoven Geotextile Fabric

Geotextiles are an essential component of modern construction and engineering projects. They are used to separate, reinforce, and stabilize the soil in a variety of applications, such as roadways, railways, airports, parking lots, retaining walls, and landscaping. Geotextiles are available in two main categories: woven and nonwoven. Each type of geotextile has unique properties and characteristics that make them suitable for specific applications.

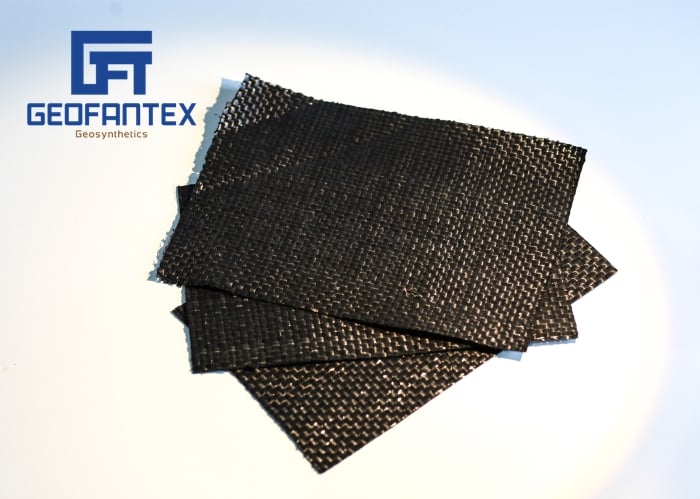

Woven Geotextile Fabric: Strength and Durability for Driveways and Roads

Woven geotextile fabrics are manufactured by weaving narrow strips of polypropylene or polyester threads into a uniform pattern. The weaving process creates a strong, durable, and stable fabric that can withstand high stress and strains. Woven geotextiles have high tensile strength, puncture resistance, and dimensional stability. They are often used in applications where the soil is stable, and there is a high risk of mechanical damage, such as driveways, parking lots, and retaining walls.

Nonwoven Geotextile Fabric: Filament Technology for Drainage and Filtration

Nonwoven geotextile fabrics, on the other hand, are made by bonding or needle-punching synthetic fibers together. The fibers are randomly oriented, which creates a highly porous fabric with high permeability and filtration properties. Nonwoven geotextiles have low tensile strength and puncture resistance but high tear resistance and elongation. They are often used in applications where drainage, filtration, and separation are critical, such as roadways, railroads, and landscaping.

Comparing Woven and Nonwoven Geotextile: Permeability and Cost Considerations

When it comes to driveways, choosing the right geotextile fabric is crucial to ensure long-term durability and stability. Both woven and nonwoven geotextiles can be used in driveways, but their selection depends on several factors, such as soil type, traffic volume, and drainage conditions.

Choosing the Right Geotextile Fabric for Your Project: Factors to Consider

For example, if the soil is stable and well-drained, a woven geotextile may be suitable to reinforce and stabilize the base course. A woven geotextile will prevent soil erosion, reduce rutting and potholes, and increase the load-bearing capacity of the driveway. However, if the soil is unstable or poorly drained, a nonwoven geotextile may be necessary to provide additional separation, filtration, and drainage functions.

Conclusion: Making an Informed Decision for Your Geotextile Fabric Needs

Another important factor to consider is the cost of the geotextile fabric. Woven geotextiles are generally more expensive than nonwoven geotextiles due to their manufacturing process and material composition. However, woven geotextiles can provide long-term cost savings by reducing maintenance and repair costs over time.

In conclusion, both woven and nonwoven geotextiles have their advantages and disadvantages when it comes to driveways and other construction applications. The selection of the right geotextile fabric depends on several factors, such as soil type, traffic volume, drainage conditions, and cost. By understanding the differences between woven and nonwoven geotextiles and their properties, engineers and contractors can make informed decisions to ensure the long-term durability and stability of their projects.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)