+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

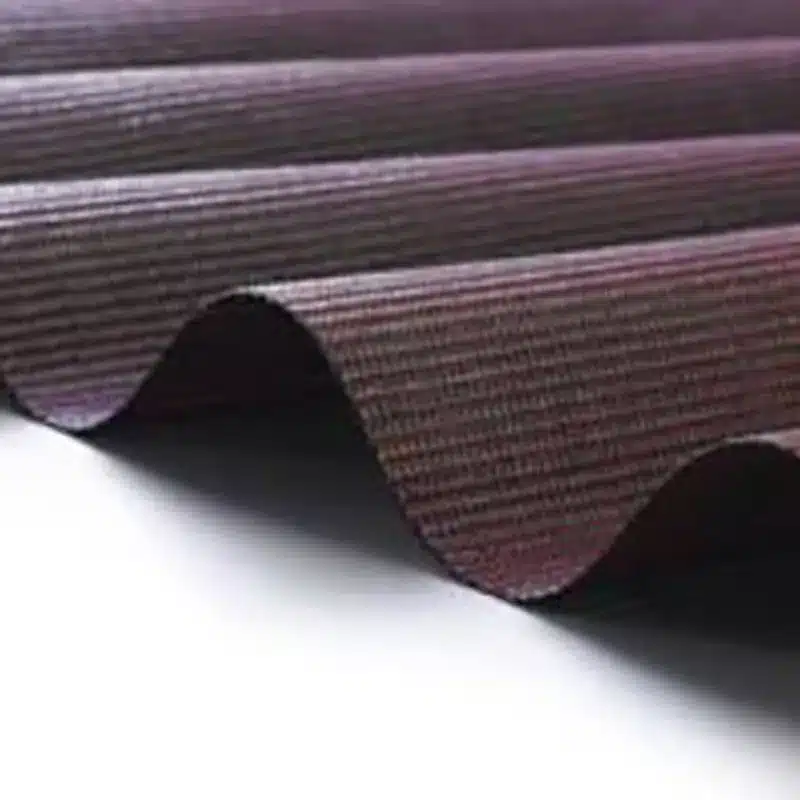

Woven geotextile fabric continues to gain momentum across global infrastructure and civil engineering markets as governments and private developers accelerate investment in resilient, cost-efficient construction solutions supported by advanced geosynthetics solutions.

Market Momentum and Industry Trends

Recent industry activity highlights a clear shift toward high-performance geosynthetics in road construction, port expansion, mining access routes, and large-scale earthworks. Rising traffic loads, compressed project schedules, and stricter sustainability targets are encouraging engineers to adopt materials that deliver consistent strength, durability, and long-term value.

In this evolving landscape, woven geotextiles are increasingly specified for separation, stabilization, and reinforcement in demanding road construction applications. Their engineered tensile properties improve load distribution, limit subgrade deformation, and extend pavement service life—critical advantages for infrastructure owners managing long-term maintenance costs.

Why Engineers Are Specifying This Solution

From both technical and commercial perspectives, decision-makers are prioritizing materials that balance performance reliability with budget efficiency. The growing preference for woven geotextile fabric is driven by its ability to enhance overall soil stabilization systems while simplifying construction workflows.

Key advantages include:

- High tensile strength to stabilize weak or variable subgrades

- Controlled elongation for predictable structural behavior

- Efficient load transfer that reduces rutting and settlement

- Lower lifecycle costs compared with traditional soil replacement

These benefits help contractors shorten construction timelines, reduce aggregate consumption, and improve bid competitiveness.

Sustainability and Compliance Considerations

Sustainability requirements are reshaping material selection across the infrastructure sector. By strengthening soils in place, woven geotextiles reduce the need for excessive excavation and aggregate hauling, contributing to lower carbon emissions and improved environmental outcomes.

At the same time, many public and private projects require strict compliance with international testing standards. Products supplied by an experienced geotextile manufacturer and supported by consistent quality control provide engineers and consultants with confidence during design approval and site inspection stages.

Commercial Value for Contractors and Distributors

Beyond technical performance, reliable supply and professional support play a decisive role in project success. Contractors and distributors benefit from working with suppliers who offer stable production capacity, clear documentation, and application-specific guidance.

When paired with responsive technical service, woven geotextile fabric solutions help reduce construction risk, prevent delays, and strengthen long-term client relationships—making them not only an engineering asset but also a strategic sales advantage.

Why Engineers and Contractors Choose GeoFanTex®

GeoFanTex® supplies engineered drainage composites tested for compressive strength, flow capacity, and durability. Our solutions integrate seamlessly with other geosynthetic products to deliver reliable performance under real-world construction conditions. By choosing GeoFanTex®, project teams reduce risk, simplify installation, and achieve predictable long-term results.

For project stakeholders seeking dependable, specification-ready solutions that improve structural integrity while controlling costs, woven geotextile fabric remains a practical and commercially sound choice for modern infrastructure development.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)