+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

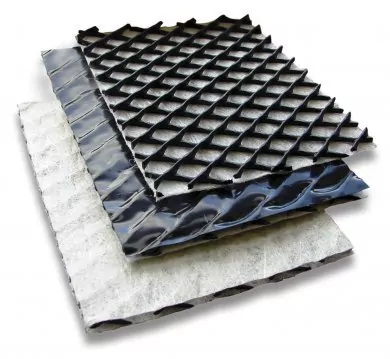

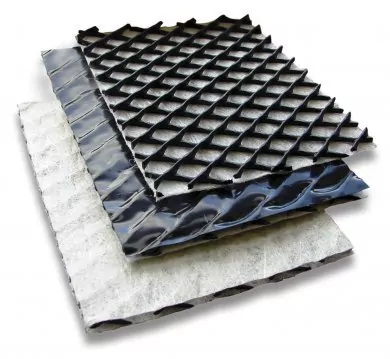

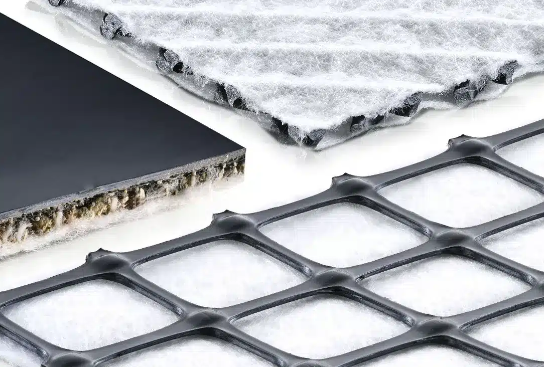

The use of geocomposite drain systems has revolutionized water management in civil engineering and geotechnical applications. These geosynthetic solutions integrate drainage cores with geotextile filters to offer superior performance in collecting and transporting water, making them indispensable in modern infrastructure projects worldwide.

Hong Kong-Zhuhai-Macau Bridge

One notable example is the construction of the Hong Kong-Zhuhai-Macau Bridge, where geocomposite drain systems were employed to address complex subgrade drainage challenges. With high water pressure present beneath the artificial island foundations, traditional drainage methods were insufficient. Engineers opted for geocomposite drains for their flexibility and efficiency, enabling rapid drainage while maintaining structural stability.

Los Angeles Metro Expansion

In another case, the Los Angeles Metro expansion project utilized geocomposite drainage layers behind tunnel linings. These systems were critical in preventing water ingress, reducing hydrostatic pressure, and extending the life of the waterproofing membrane. Their thin profile and ease of installation made them ideal for urban tunneling projects where space and time constraints were major considerations.

Canadian Oil Sands Tailings Dams

A third significant application was seen in the Canadian oil sands industry. Tailings dams in Alberta posed high-risk seepage problems, and the deployment of geocomposite drain layers provided an efficient, lightweight alternative to gravel drainage. These solutions improved drainage performance while reducing the environmental footprint and transport costs associated with traditional materials.

These cases highlight the growing demand for geosynthetic solutions that balance performance, cost-efficiency, and environmental sustainability. As geotechnical challenges evolve, geocomposite drain products continue to prove their value across diverse, high-stakes applications.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)