+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

BX1200 geogrid is a biaxial polypropylene geogrid commonly used for road construction, gravel driveways, and subgrade stabilization. This article answers four key questions about bx1200 geogrid, its performance, applications, and market context.

What is BX1200 Geogrid and how does it work?

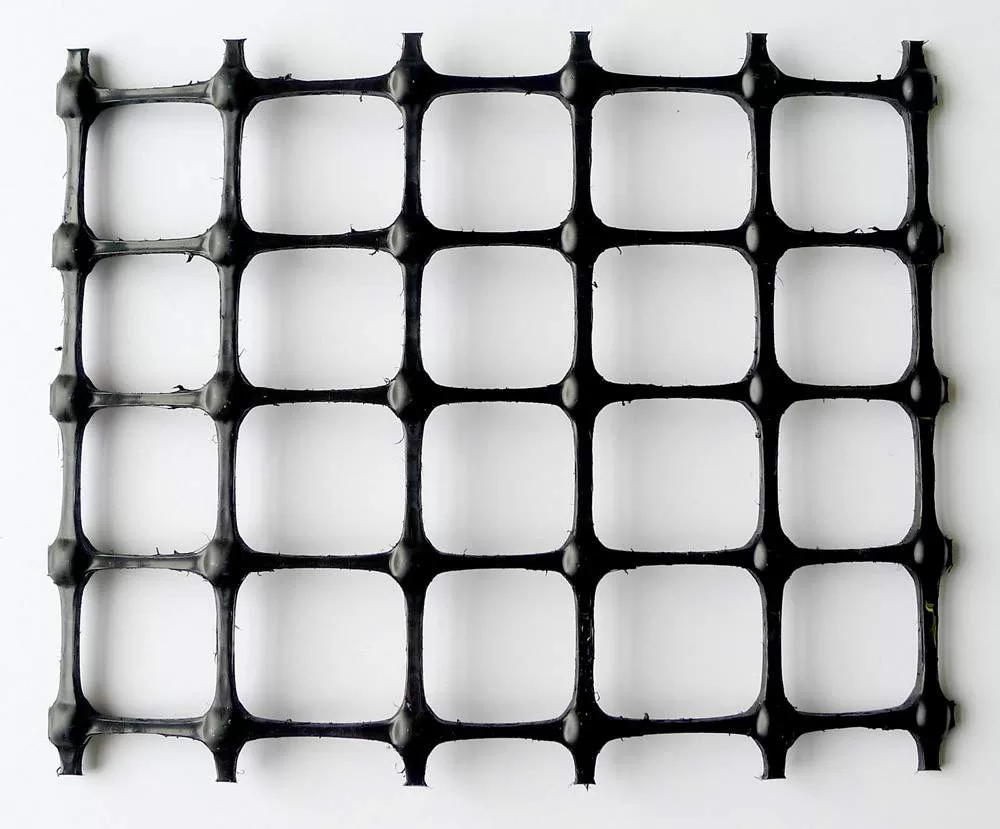

- Product Definition: BX1200 is a biaxial polypropylene (PP) geogrid manufactured by punching and stretching polypropylene sheets in two perpendicular directions to form a rigid grid with uniform apertures.

- Working Mechanism: The grid structure allows aggregate particles to lock into the apertures, creating mechanical interlock. This interlock provides lateral restraint, improved load distribution, and reduces rutting and settlement under traffic loads.

- Performance: According to ASTM D6637 standards, BX1200 has a tensile strength of approximately 12 kN/m in both machine and cross-machine directions. High junction efficiency ensures stability under repeated loading and demanding conditions.

- Engineering Benefits: BX1200 enhances subgrade stabilization, reduces aggregate layer thickness, and extends the service life of roads, driveways, and construction platforms.

Where is BX1200 Geogrid most effectively used?

Common applications include:

- Gravel driveways and residential access roads.

- Temporary construction roads and work platforms.

- Base reinforcement under flexible pavements.

- Parking areas and storage yards on weak soils.

By reinforcing the base, BX1200 can reduce aggregate thickness by 20–40%, cutting material costs and lowering hauling requirements. This not only saves money but also reduces the project’s carbon footprint by minimizing aggregate transport.

What specifications and installation details should be considered?

- Strength values: Designers should use Minimum Average Roll Values (MARV) rather than nominal values for safety. For BX1200, MARV tensile strength is about 12 kN/m.

- Installation: The geogrid must be placed directly on the prepared subgrade, free of wrinkles, with recommended overlaps of 0.3–0.6 m depending on soil conditions.

- Durability: Polypropylene geogrids like BX1200 provide chemical resistance and long-term durability. They should be covered with aggregate soon after installation to protect against UV exposure. Check installation best practices for more guidance.

Why is the demand for BX1200 and geogrids increasing?

The growth is driven by infrastructure investment and the push for sustainable construction. Geogrids reduce aggregate consumption, improve road performance, and extend pavement life. Industry studies show that the global geogrid market exceeded USD 1.2 billion in 2023, with a projected annual growth of over 5% in the next decade. At the same time, the broader geosynthetics market surpassed USD 16 billion in 2024, reflecting widespread adoption across civil engineering. Learn more about geosynthetics solutions.

BX1200 geogrid is a proven solution for stabilizing weak soils, reducing aggregate costs, and improving the performance of driveways and road projects. Its balance of strength, durability, and cost efficiency makes it one of the most widely used biaxial geogrids in the industry.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)