+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

When it comes to building a stable gravel surface, choosing the best geogrid for gravel driveway can make the difference between a driveway that lasts decades and one that requires constant maintenance. Geogrids are one of the most widely used geosynthetics because they improve soil-aggregate interaction, extend service life, and reduce material costs.

Industry data highlights:

- Using geogrid can reduce aggregate thickness by up to 50%, according to geotechnical performance studies.

- Field trials show rutting reductions of 30–50% when geogrids are applied in unpaved road and driveway projects.

- Cost savings of 15–25% are achievable due to reduced stone usage and extended maintenance intervals.

What type of geogrid is the best for gravel driveways?

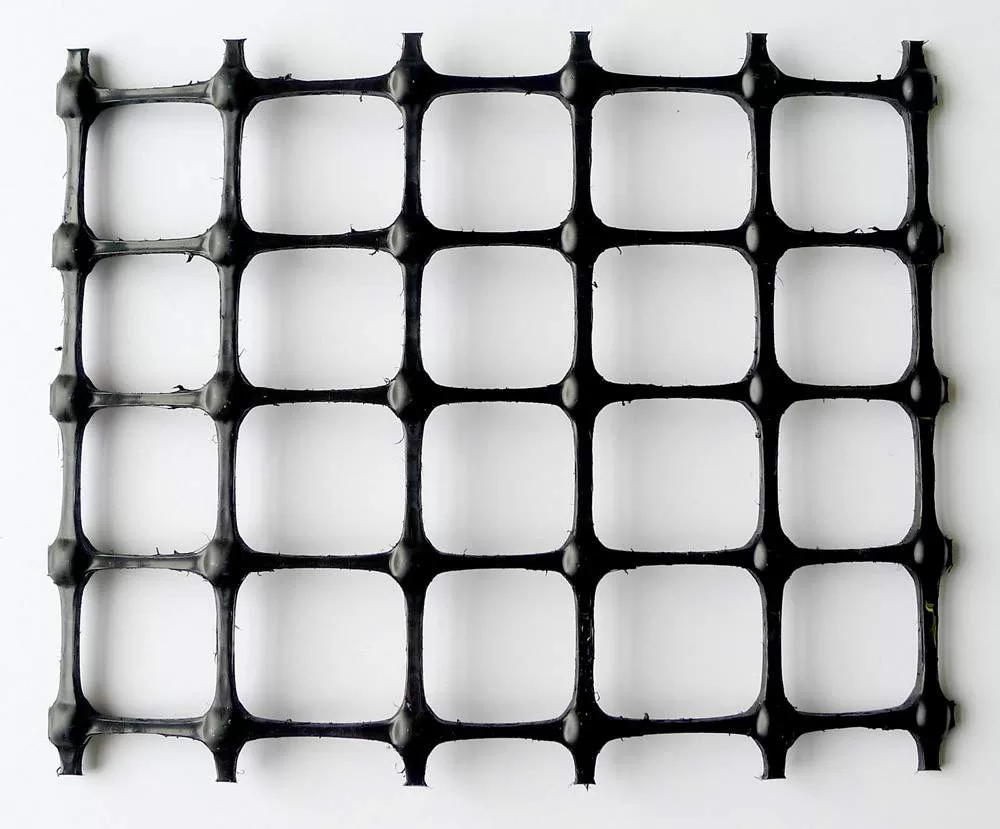

For most residential and light commercial gravel driveways, biaxial geogrid is considered the most practical choice. It provides tensile strength in two directions, which helps lock gravel into place and distribute loads evenly. For heavier traffic or weaker soils, triaxial geogrid may be more effective because it delivers load distribution in multiple directions, offering greater stability.

👉 Learn more about biaxial and triaxial geogrids and their applications in driveway and road construction.

How does geogrid improve gravel driveway performance?

Geogrids interlock with the gravel aggregate, creating a reinforced layer that resists rutting, washouts, and pothole formation. By spreading wheel loads over a wider area, they protect the subgrade from excessive stress. This means less gravel migration, fewer maintenance cycles, and longer service life. In fact, many tests confirm that geogrids can increase bearing capacity by up to 200% compared to unreinforced gravel sections.

What installation practices ensure maximum efficiency?

Proper installation is critical to realizing the benefits of the best geogrid for gravel driveway:

- Subgrade preparation: Remove vegetation, level the surface, and compact weak soils.

- Geogrid placement: Roll the geogrid directly on the compacted subgrade with overlaps of 30–45 cm.

- Aggregate filling: Place gravel in layers, ensuring that the geogrid apertures are filled and compacted. Avoid driving directly on exposed geogrid.

For detailed installation guidance, visit Geogrid Installation Solutions.

How cost-effective is geogrid for gravel driveways?

Although geogrids add an upfront material cost, the long-term savings outweigh the expense. By reducing gravel consumption and extending the life of the driveway, they lower the total lifecycle cost. Contractors often report that for every dollar spent on geogrid, two to three dollars are saved in reduced aggregate and maintenance. This makes geogrid not only an engineering solution but also an economical one.

The best geogrid for gravel driveway depends on site conditions and expected traffic. Biaxial geogrid suits most residential uses, while triaxial is ideal for heavier loads or soft soils. With proven data on cost savings, performance, and sustainability, geogrids are now a best practice for modern driveway construction.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)