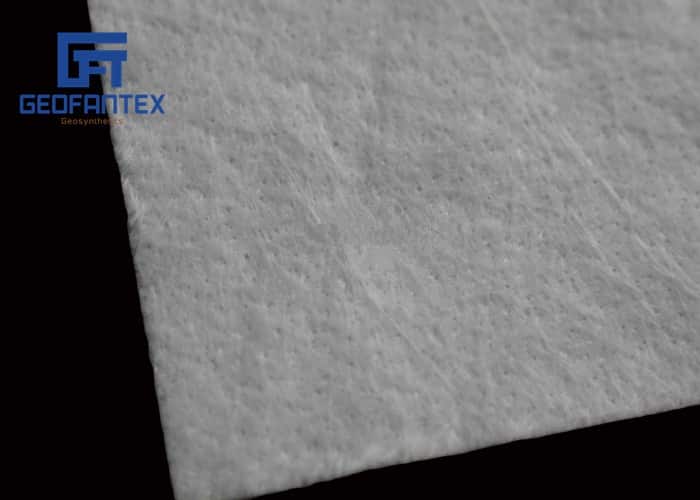

Nonwoven Geotextiles

Terram T1000 Non Woven Geotextile Membrane – Custom Size

- Brand GeoFanTex® GFE

- Product origin China

- Delivery time 7-14 days

- Supply capacity 40′ HQ/ 7 Days

Product Details

Polyester Nonwoven Geotextiles GeofanTex® GFE has main functional mechanical properties, permeable or impermeable properties, and soil-tightness. The datasheet as the blow is part of mechanical properties, not full of it. The permeable properties, loading quantities, or other details will be mailed to you if needed. As bellows.

(* Geofantex Geosynthetics can produce GeofanTex® GFE according to your requirement in constructions, MINIMUM ORDER QUANTITY: 20’ft Container)

Nonwoven Geotextile Fabric Specifications

| Properties (Standard) | Unit | GFE 100 | GFE 150 | GFE 200 | GFE 250 | GFE 300 | GFE 350 | GFE 400 | GFE 450 | GFE 500 | GFE 550 | GFE 600 | GFE 800 | |

| Tensile Strength [ASTM D 4595] | T M | KN/m | 7.7 6.0 | 11.6 9.1 | 14.6 11.4 | 18 14.3 | 21 15.6 | 24 21 | 28 23 | 30 24 | 35 30 | 38 30 | 42 32 | 56 46 |

| Tensile Elongation [ASTM D 4595] | T M | % | 80 50 | 70 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 |

| Grab Strength [ASTM D 4632] | T M | N | 420 330 | 630 420 | 810 570 | 1070 760 | 1310 1060 | 1520 1120 | 1740 1260 | 1990 1600 | 2500 1910 | 2750 2070 | 3130 2310 | 3490 2530 |

| Grab Elongation [ASTM D 4632] | T M | % | 80 50 | 70 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 | 60 50 |

Non Woven Geotextile Fabric Advantages

Geofantex® GFE is 100% Polyester Continuous Filament Needle Punched non-woven Geotextile. Typically, this form of manufacturing offers superior hydraulic performance and high resistance to site installation stresses due to the nature of the continuous filament structure.

1. Nonwoven Geotextile Fabric For Separation

Use Polyester Continuous Filament Needle Punched non-woven Geotextile to separate building materials (such as soil and sand, soil and concrete) with different physical properties (particle size, distribution, consistency and density, etc.). Two or more materials are not lost or mixed, the overall structure and function of the materials are maintained, and the load-bearing capacity of the structure is strengthened.

2. Nonwoven Geotextile Fabric For Filtration

When water flows from the fine material soil layer into the coarse material soil layer, the good air permeability and water permeability of the Polyester Continuous Filament Needle Punched non-woven Geotextile are used to allow the water to pass through, and effectively carry the soil particles, fine sand, small stones, etc. Maintain the stability of water and soil engineering.

3. Nonwoven Geotextile Fabric For Drainage

Polyester Continuous Filament Needle Punched non-woven Geotextile has good water conductivity. It can form a drainage channel inside the soil and drain the excess liquid and gas from the soil structure.

4. Nonwoven Geotextile Fabric For Reinforcement

Use acupuncture geotextiles to enhance the tensile strength and deformation resistance of the soil, increase the stability of the building structure, and improve the soil quality.

5. Nonwoven Geotextile Fabric For Protection

When the water flow scours the soil, it effectively spreads, transmits or decomposes the concentrated stress, prevents the soil from being damaged by external forces, and protects the soil.

6. Nonwoven Geotextile Fabric Composite

Combined with the geomembrane, it becomes a composite waterproof and impermeable material, which plays a role of preventing puncture. High tensile strength, good permeability, air permeability, high-temperature resistance, freezing resistance, aging resistance, corrosion resistance, and no insects.

Applications of Non Woven Geotextile

Roads

Nearly every road built today uses a nonwoven geotextile such as bidim, to provide separation and filtration under the road formation. The ingress of water into road pavements poses the most significant damage potential to any road; therefore rapid removal of this water is of the utmost importance. bidim is the only bidimensional geotextile on the market today – meaning it has the same strength properties in both directions.

Standard road construction practice requires the inclusion of road edge drainage systems which incorporate geotextiles; in order to optimise performance of these drains a geotextile with high flow rates is desirable. The three dimensional structure of the nonwoven geotextile provides numerous flow paths, with the result that bidim geotextiles allow water to flow at rates which exceed most natural materials it is placed in contact with.

Rail Formation

bidim geotextiles are commonly used in the rail sector to separate the capping layer form the ballast layer, providing separation and filtration. The rail industry typically demands bespoke bidim grades due to the nature of their aggregates and applied loads.

Embankments

High quality fill material can become contaminated when it is placed directly in contact with a soft or poor quality ground; the result being a loss of performance of the fill material. In order to limit the contamination and subsequent strength loss, geotextiles are used to separate the two distinct materials. Construction in this environment can place the geotextile separator under high stress with forces from rock placement and equipment loads needing to be transferred into the poor quality material. bidim geotextiles are ideal for this application as it combines high elongation with high strength to provide unsurpassed toughness and survivability characteristics.

Liner Protection

Heavy duty geotextiles are used to prevent damage to impermeable liners designed to contain harmful liquors in landfill and mining applications; the design of the liner system needs to limit the chance of punctures during installation and reduce the risk of long term stress cracking of the geomembrane. Research has shown that bidim geotextiles can significantly reduce forces placed on the impermeable liners, protecting them in both the short and long term. Needle free bidim is commonly specified in liner protection applications to help prevent damage to the liner.

Residential, Plumbing & Landscaping

For small residential, plumbing and landscaping drainage and filtration applications we recommend the use of our Filterwrap (link is external) product.

Filterwrap is supplied in small easy to handle roll sizes and is designed to replace natural filters in many applications particularly revetments and subsoil drainage. The extremely high porosity of nonwoven geotextiles allows water flow while preventing fines migration. These properties allow Filterwrap to be used where drainage or control of groundwater is a concern such as behind retaining walls, working over soft ground in driveway construction and gravel paths or in landscaping applications to provide separation between soil and drainage aggregates in planter boxes and roof gardens.

Geofantex Geosynthetics have to make a series of guarantee for our products both plant processing and selling out to our customers. The selling to you is the first step, the service, and guarantee is our task. Geofantex Geosynthetics have an ISO Certificate to guarantee the raw material, the product processing, and the end product. From receiving your order to replacement and installation of the products, we have solved the problems in time if you need, whatever the quality and technics guideline or suggestions. Our company has been committed to supplying high-quality products with reasonable price and delivery in time.

MANUFACTURING QUALITY ASSURANCE

GEOFANTEX has an on-site Manufacturing Quality Assurance Laboratory at factory. GEOFANTEX maintain a high level of quality and up-to-the-minute results on finished products through a fully equipped, well staffed, dedicated laboratory existing in each of the manufacturing facilities. Each facility follows the same guidelines for evaluating the quality of GEOFANTEX products and is capable of adapting to market-driven requirements.

A. Objective

The objective of the GEOFANTEX Quality Assurance program is to define implementation of basic manufacturing quality assurance (MQA) procedures necessary to ensure consistent production of quality products supplied to the geosynthetic market. Note that at this time, these procedures are limited to Polyester (PET) Continuous Filament Nonwoven Geotextile

B. Scope

In order to achieve GEOFANTEX’s stated purpose, a rigorous set of minimum standards and an effective test program to assure compliance has been established. These procedures and requirements are frequently reviewed and adjusted to assure compliance with current market demands and/or predetermined project specifications. These procedures assure that raw materials and process parameters are controlled to provide products complying with GEOFANTEX’s pre-defined minimum characteristics.

PRODUCT IDENTIFICATION AND DOCUMENTATION

A. Roll Numbering

Each roll of geotextile is assigned a unique roll number. The Quality Assurance Laboratory maintains records documenting the raw materials and resulting product quality information.

B. Approval Procedure

Results for each tested roll of product are checked against both GEOFANTEX China standard and customer specifications for compliance. The Quality Assurance Laboratory approves those materials that meet these requirements for shipment.

C. Non-Conformance

Material that does not meet GEOFANTEX minimum standards is given a roll number, but is rejected and not placed into inventory. The material is identified as scrap and will not be utilized. Material that meets GEOFANTEX minimum standards but does not meet a stricter customer specification is not allocated to that customer, but is placed into inventory as GEOFANTEX standard material.

D. Documentation

Individual Quality Assurance Certificates are generated and supplied for each roll of needle punched nonwoven geotextile product to include all relevant quality assurance information about the material(s).

Geofantex Geosynthetics have a series of package and delivery service working procedures. Geofantex Geosynthetics have supply thousands of containers to Latin America, North America, Southeast Asia and developed countries and Africa within the past ten years. We provide the package of products with the rolls, pots, bags, sheets, or your requirement in orders. Our company has been committed to supplying high-quality products with reasonable price and delivery in time. Delivery one 40’HQ within 7 – 10 days. And we have an obligation in increasing loading quantity and make you save the freight costs maximally. We supply the products by plane, by sea and land carriage to any regions or any countries of the worldwide, even the door-to-door service.

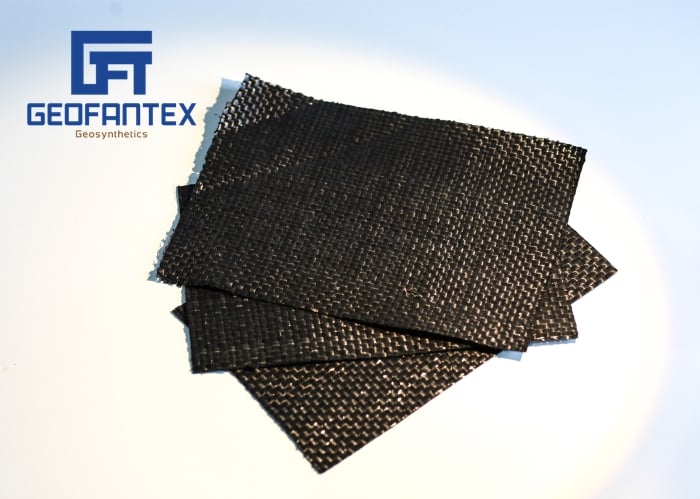

| SEPARATION | REINFORCEMENT | FILTRATION | DRAINAGE | WATERPROOF | PREVENTION | POLLUTION PREVENTION | PROTECTION | CONSOLIDATE | |

| GEOTEXTILE | √ | √ | √ | √ | √ | √ | |||

| GEOMEMBRANE | √ | √ | √ | ||||||

| GEOGRID | √ | √ | |||||||

| GEONET | √ | ||||||||

| GEOTUBE | √ | ||||||||

| GEOCELL | √ | √ | |||||||

| GCL | √ | √ | |||||||

| GEOCOMPOSITE | √ | √ | √ | √ | √ | √ | √ | ||

| GEOCONCRETE BLANKET | √ | √ | √ | ||||||

| Drainage Board B | √ | √ | √ | √ | |||||

| Storage and Drainage Board | √ | √ | √ | √ | |||||

| Grass Paver | √ | √ | √ | √ | √ | √ | √ | ||

| Macmat | √ | √ | √ | √ | √ | √ | √ | ||

| GeoFanTex®GD 2L | √ | √ | √ | √ | √ | √ | |||

| GeoFanPipe® FP | √ | ||||||||

| GeoFanDrain® BC | √ | √ | √ | ||||||

| GeoFanPipe® DCP | √ | √ | |||||||

| GeoFanTRM® Geomantles | √ | √ | √ | √ | √ |

What is Polyester (PET) Continuous Filament Nonwoven Geotextile (GeofanTex® GFE)

Polyester (PET) Continuous Filament geotextile is polyester filament needle-punched non-woven geotextile fabric. It does not contain chemical additives and does not undergo heat treatment. It is an environmentally friendly building material. Furthermore, it can replace traditional engineering materials and construction methods, making construction safer, and has contributed to environmental protection, it can solve the basic problems in project construction more economically, effectively and lastingly.

PET (Polyester) Long Fiber Nonwoven Geotextile (GeoFanTex ® GFE) is 100% Polyester Continuous Filament Needle Punched non-woven Geotextile, with maximum 6m-width. These synthetic fibers are made into flexible, porous fabrics by standard weaving machinery or are knitted in a random nonwoven manner. The major point is that PET(Polyester) Long Fiber Nonwoven geotextiles are porous to liquid flow across their manufactured plane and also within their thickness, but to a widely varying degree. PET Long Fiber Nonwoven Geotextile (GeoFanTex ® GFE) have a very high melting point and UV resistance and have many applications in filtration and separation, protection and drainage.

Polyester long fiber non-woven geotextile has an excellent heat resistance and light resistance. Even if it is exposed to a short-term environment of nearly 20 ℃, its performance has almost not change. After a large number of tests and practices, the polyester long fiber non-woven geotextile has long-term corrosion resistance to various natural soils, moisture, and microorganisms.

The package of nonwoven geotextile is PE, the color of the package is black, the MOQ (minimum order quantity)of white of is 20’GP, the one of grey is 40’HQ, the PET(Polyester) Long Fiber Nonwoven Geotextile (GeoFanTex ® GFE) could be made into a bag, pot, roll or according to customers’ requirements.

Development history of the Geofantex

2014 — Geofantex Geosynthetics Co., Ltd. Factory was established

2015 — promoting the new image and building GeoFanTex brand

2018 –Geofantex products exceeded 100 million dollar

2019 — Upgrade new nonwoven geotextile, Geomembrane, and Composite geomembrane production line.

2020 — The new factory was completed.

2021 — Upgraded production line of the factory, making all the products could meet ASTM, AS, and ISO standards.

2022— Improve the quality of after-sales service and launch customized products.

Company Profile

Geofantex Geosynthetics Co., Ltd. is located in the beautiful coastal city of Dalian, with superior geographical location, convenient transportation, and developed communications. The company was founded in 2014 with a registered capital of 5,000,000 yuan. It has an industrial park covering an area of more than 50 acres in Jinan, Shandong. It has a modern office environment, advanced production equipment, and a group of high-quality and professional technical and management personnel.

The company gives full play to its own innovation advantages, platform advantages, and market advantages, and with the support of national policies, builds a national first-class enterprise, always follows the principle of “quality first, reputation first”, adhering to the principle of “people-oriented, quality for survival, integrity, unity and hard work”, Integrated enterprise spirit, sincere cooperation with various engineering units and colleagues from all walks of life, harmonious development, and work together to make greater contributions to infrastructure.

Frequently Asked Questions

Get Free Sample

We’ll respond as soon as possible(within 12 hours)

Rail

Roads

Sports & Recreation

Civic & Landscaping

Waste & Containment

Mining & Resources

Ports & Aviation

Building

Underground Mining

Sector Suitability

- Rail

- Roads

- Sports & Recreation

- Civic & Landscaping

- Slopes & Walls

- Waste

- Mining

- Coastal

- Ports & Aviation

- Primary Industries

- Water

- Building

- Erosion & Sediment Control

bidim geotextile is the most well known nonwoven geotextile product on the market today. It leads the way in terms of technical performance and versatility and has applications in virtually every civil engineering construction project.

bidim nonwoven geotextiles provide an effective, economical solution to a range of engineering problems including weak soil, rutted and cracked roads and liquid and gas leaks from landfill sites. All bidim nonwoven geotextiles are manufactured in Australia to ISO 9001 standards and are supported by a rigorous MQA process as well as being designed to meet the requirements of Australian and New Zealand road authorities.

Function

bidim nonwoven geotextiles provide excellent filtration and features a strong three-dimensional structure with high elongation. bidim nonwoven geotextiles also have a high melting point and high UV resistance.

Drainage

bidim nonwoven geotextiles have a three-dimensional structure designed to improve drainage performance. Ideal for use in subsoil drainage systems, bidim will assist in the removal of water from road and railway works, sports fields and behind retaining walls.

Separation

bidim nonwoven geotextiles are used in the construction of roads, railways and embankments where the ground is soft and unstable. Using a layer of geotextile to separate the soft ground from the fill material will reduce the amount of fill required, increase the life span of the road or rail structure and cut long-term maintenance costs.

Filtration

bidim nonwoven geotextiles are highly porous, allowing water to pass through while preventing soil migration. When used in revetment and subsoil drainage projects, bidim geotextiles are more cost effective than natural filters.

Protection

Using heavyweight bidim nonwoven geotextiles in landfills extends the life of the lining system by protecting it from punctures and excessive deformation. The geotextile acts as a cushioning and stress relieving layer, minimising the chances of leakage in the long term. Needle free bidim geotextiles are commonly specified in landfill and containment applications to prevent damage to the underlying liner.

Advantages

- The incorporation of bidim geotextiles reduces the need for quarried fill materials and reduces construction times.

- Tightly rolled wide rolls can result in significant transportation cost savings.

- Local production of bidim allows full QA traceability of every roll, with many customers auditing our local production facilities.

- Needle free bidim geotextiles provide designers and installers in the waste and containment sectors with confidence that their liner will not be damaged.

- Local UV testing conducted over many years, which important as we have one of the most extreme UV environments in the world.

- Centre of Excellence research and testing into use of bidim as a cushion layer, yielding savings to contractors and asset owners.

- Local production of bidim allows for production of project specific grades or roll dimensions.

- Complies with all road, rail and landfill authority specifications.

- Local stock holdings ensure we have the right product in the right place at the right time.

Installation

bidim geotextiles are supplied fully wrapped in rolls up to 6m in width to minimise wastage and laps. bidim is also available in a range of grades including A14, A19, A29, A34, A39, A44, A49 and A64.

Installation can be assisted with the use of a Geofabrics supplied spreader bar. For more detailed installation instruction refer to our comprehensive Storage & Installation Guide.