+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

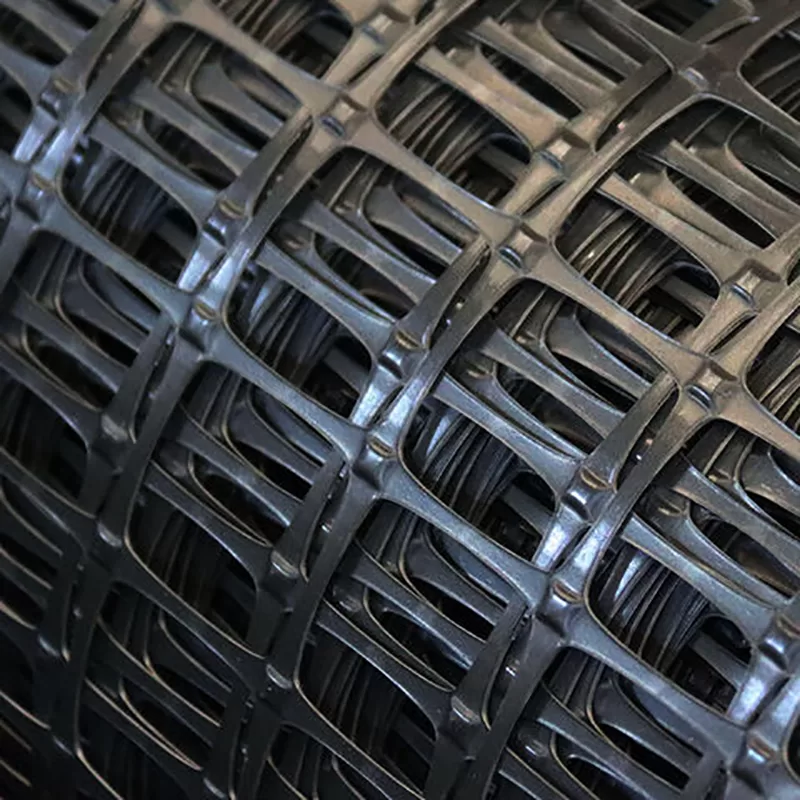

Geogrids serve as the backbone of modern construction and civil engineering projects, offering an array of types tailored to specific needs. Understanding the nuances and applications of various geogrid types is pivotal in optimizing infrastructure durability and stability. From biaxial to uniaxial, woven to geocomposite grids, each variant possesses unique strengths ideal for diverse soil reinforcement and ground stabilization tasks. Delve into this comprehensive guide to unearth the distinctive characteristics, advantages, and best use cases for each type of geogrid, empowering your projects with informed decision-making and enhanced structural efficiency.

What are the types of geogrid?

- Uniaxial Geogrids: geosynthetic materials made from polymers, typically high-density polyethylene (HDPE) or polypropylene (PP). Uniaxial geogrids have a primary load-bearing direction and are designed to provide strength and reinforcement in one direction. They are commonly used in applications such as road and railway construction, embankment stabilization, and reinforced soil walls.

- Biaxial Geogrids: like uniaxial geogrids, are made from polymers such as HDPE or PP. However, unlike uniaxial geogrids, they provide strength and reinforcement in two perpendicular directions. Commonly used in road construction, parking lots, soil stabilization, pavement construction, and other civil engineering projects.

- Triaxial Geogrids: are an advanced type of geosynthetic material that provides strength and reinforcement in three principal directions. Triaxial geogrids are commonly used in applications such as road and railway construction, mechanically stabilized earth (MSE) walls, and reinforced foundations.

- Multiaxial Geogrids: are geosynthetic materials that provide strength and reinforcement in multiple directions, typically more than three. Multiaxial geogrids find applications in various fields, including road and railway construction, embankment stabilization, retaining walls, underground structures, railway tracks, and landfill slopes.

- Composite Geogrids: Composite geogrids are a combination of geogrids and other geosynthetic materials, such as non-woven geotextiles or geomembranes. These geogrids offer additional functionalities, such as soil filtration, separation, or erosion control, in addition to their primary reinforcement function.

What are the types of geogrids by material?

Geogrids can be classified based on the material they are made from. The commonly used materials for geogrids include:

- Polypropylene (PP) Geogrids: Polypropylene geogrids are one of the most widely used types. They are lightweight, durable, and have excellent resistance to chemicals, UV degradation, and biological degradation. PP geogrids are suitable for a wide range of applications, including soil reinforcement, retaining walls, and pavement stabilization.

- Polyester (PET) Geogrids: Polyester geogrids are known for their high tensile strength and stiffness. They offer excellent resistance to creep and are often used in applications that require long-term reinforcement, such as embankments, slopes, and mechanically stabilized earth (MSE) walls.

- High-Density Polyethylene (HDPE) Geogrids: HDPE geogrids are characterized by their high tensile strength, resistance to chemical and biological degradation, and ability to withstand harsh environmental conditions. They are commonly used in applications such as retaining walls, soil stabilization, and reinforcement of soft soils.

- Fiberglass Geogrids: Fiberglass geogrids are made from woven or non-woven fiberglass strands and offer high tensile strength and resistance to creep. They are used in applications that require high-strength reinforcement, such as road construction, pavement overlays, and soil stabilization in soft ground conditions.

- Steel Geogrids: Steel geogrids are made from high-tensile steel wires or welded steel grids. They provide exceptional strength and stiffness and are used in applications that require heavy-duty reinforcement, such as bridge abutments, railway tracks, and soil stabilization in areas with high loads.

- Composite Geogrids: Composite geogrids are geogrids that are reinforced or combined with other materials, such as geotextiles or geomembranes. These combinations enhance the geogrid’s functionality and allow for multiple engineering requirements, such as filtration, separation, and reinforcement.

What is the most common material used for geogrid?

The most common material used for geogrids is high-density polyethylene (HDPE) or polypropylene (PP). These polymers are preferred because they offer excellent tensile strength, resistance to environmental degradation, and chemical stability. HDPE and PP are particularly suitable for geogrid construction due to the following characteristics:

- High Tensile Strength: They provide strong reinforcement, enhancing soil stability and improving the load-bearing capacity of roadways, retaining walls, and other geotechnical structures.

- Durability: These polymers are resistant to soil chemicals, biological degradation, and ultraviolet radiation, which increases the geogrid’s lifespan, even under harsh environmental conditions.

- Flexibility: Their flexibility allows geogrids to conform to varying soil surfaces, making them versatile for different geotechnical applications.

- Lightweight and Easy to Install: They are lightweight yet sturdy, making them efficient and cost-effective to transport and install.

What is the lifespan of Geogrid?

The typical lifespan of a Geogrid, a geosynthetic material used for soil reinforcement, can vary significantly. Its longevity depends on several factors:

- Material Type: Geogrids made from high-quality polymers like polypropylene or polyester generally have longer lifespans, often exceeding 50 years.

- Exposure Conditions: Environmental exposure like UV radiation, chemicals, or extreme temperatures can degrade the material over time, reducing lifespan.

- Load and Stress: The amount and frequency of load the Geogrid bears affect its durability.

- Installation Quality: Proper installation ensures the Geogrid performs optimally, reducing the likelihood of premature failure.

- Maintenance: Regular inspections can identify issues like overloading or damage, allowing for timely repairs.

By considering these factors, the lifespan of Geogrids can be managed effectively, ensuring long-term stability in construction and infrastructure projects.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)