+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Product Details

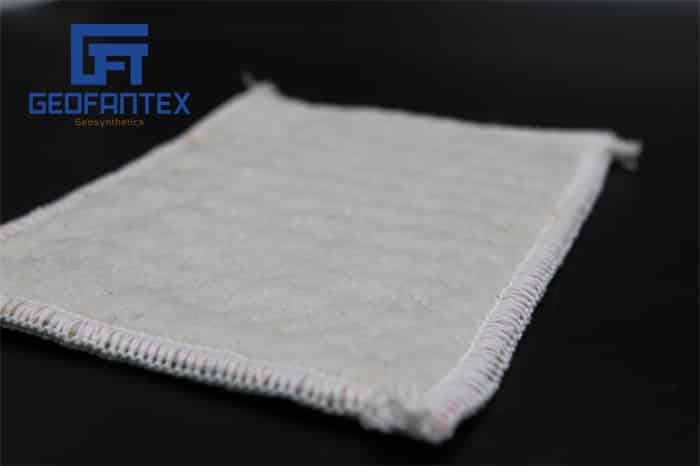

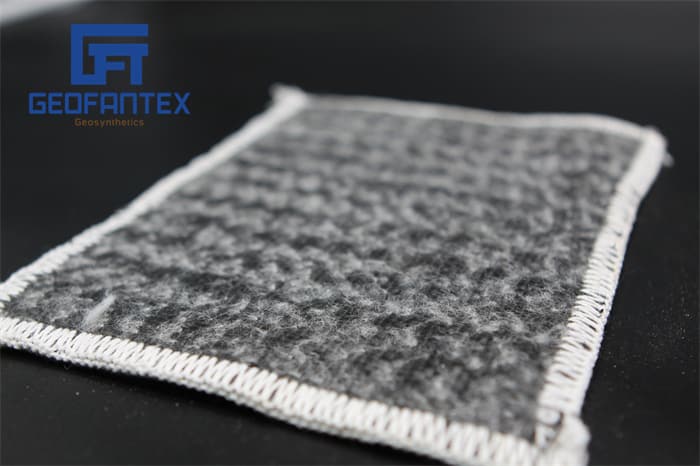

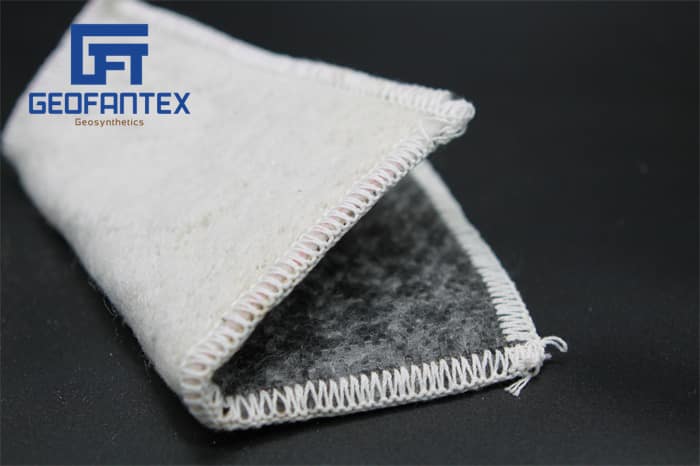

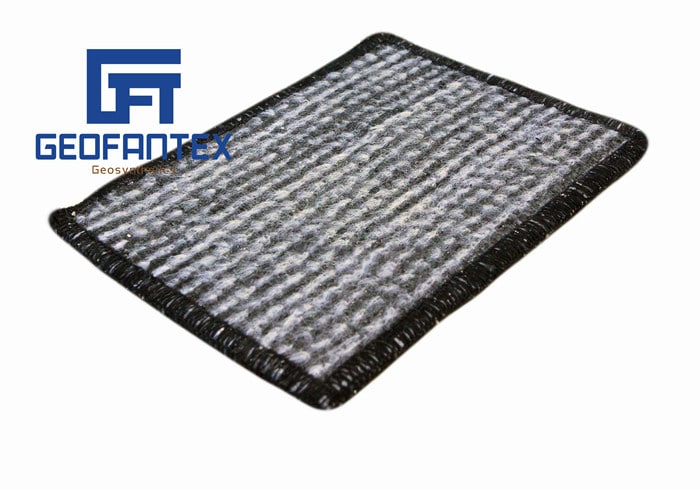

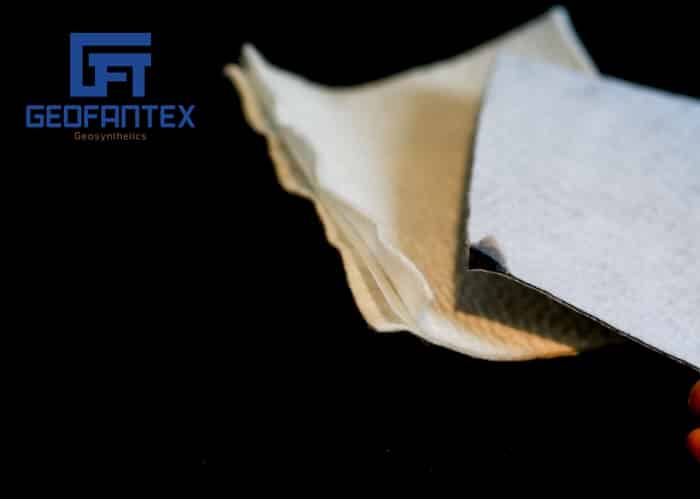

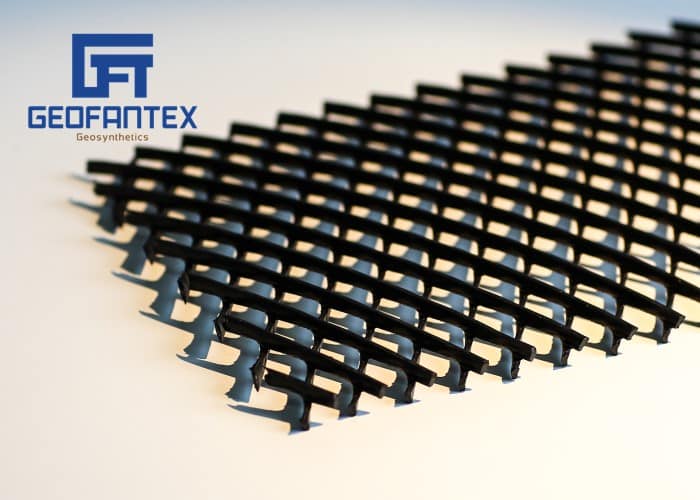

Geosynthetics Clay Liner (GCL)

Geosynthetics Clay Liner is a kind of geosynthetic material specially used for preventing seepage of artificial lakes, waterscapes, landfills, underground garages, roof gardens, swimming pools, oil depots and chemical storage yards. It is made of highly expansive sodium-based bentonite which is filled between special composite woven geotextile and non-woven geotextile. Bentonite impermeable pad made by needle-punching can form many small fiber gaps. Bentonite particles cannot flow in one direction and stay in the pad when they meet water. A uniform and high-density colloidal impermeable layer is formed to effectively prevent water leakage.

Could be manufactured according to your inquiry, MINIMUM ORDER QUANTITY: 20ft container

Mechanical Propertie

| Properties | Standard | Unit | GCL – NP |

| Top/Cap Nonwoven Geotextile | ASTM D 5261 | g/m2 | 200 |

| Woven Geotextile | ASTM D 5261 | g/m2 | 100 |

Bentonite Properties

| Properties | Standard | Unit | GCL – NP |

| Weight | ASTM D 5993 | g/m2 | 4,500 |

| Swell Index | ASTM D 5890 | ml/2g (≥) | 24 |

| Moisture Content | ASTM D 4643 | % | 12 |

| Fluid Loss | ASTM D 5891 | ml | 18 |

Finished GCL Properties

| Properties | Standard | Unit | GCL – NP |

| Mass Per Unit | g/m2 (≥) | 4800 | |

| Blue Absorption Capacity | g/100g (≥) | 30 | |

| Tensile Strength | ASTM D 4632 | N/100mm (≥) | 600 |

| Elongation at Break | %(≥) | 10 | |

| Peel Strength | ASTM D 6496 | N/100mm (≥) | 40 |

| CBR Puncture Resistance | ASTM D 6241 | KN(≥) | 2 |

| Permeability | ASTM D 5887 | m/s(≤) | 5.0×10-11 |

| Hydrostatic Pressure-Resistant | 0.4MPa,lh No infiltration | ||

| Index Flux | (m3 /m2 )/s (≤) | 1 x 10-8 | |

| Bentonite Wear | ml/2g | ≥24 | |

| Soaked Pressure- Resistance | ASTM D 5321 | ≥24KPa Typical |

Applications of Geosynthetic Clay Liner (GCL)

- It is used for stabilizing subgrades of roads and railways.

- Waterproofing of municipal engineering, underground engineering of subways, buildings and roof tanks.

- Environmental protection and sanitation, domestic waste landfill, sewage treatment plant, industrial waste.

- Water conservation, leakage prevention, plugging and reinforcement of rivers, lakes, reservoirs and dams.

- Waterproofing of ponds in gardens, artificial lakes, golf courses, etc.

- Waterproof, anti-corrosion, anti-leakage, reinforcement, etc. in petrochemical, mining, agricultural and other fields.

Geofantex Geosynthetics have to make a series of guarantee for our products both plant processing and selling out to our customers. Selling to you is the first step, the service, and guarantee are our tasks. Geofantex Geosynthetics have an ISO Certificate to guarantee the raw material, the product processing, and the end product. From receiving your order to replacement and installation of the products, we have solved the problems in time if you need, whatever the quality and technics guidelines or suggestions. Our company has been committed to supplying high-quality products with reasonable prices and delivery on time.

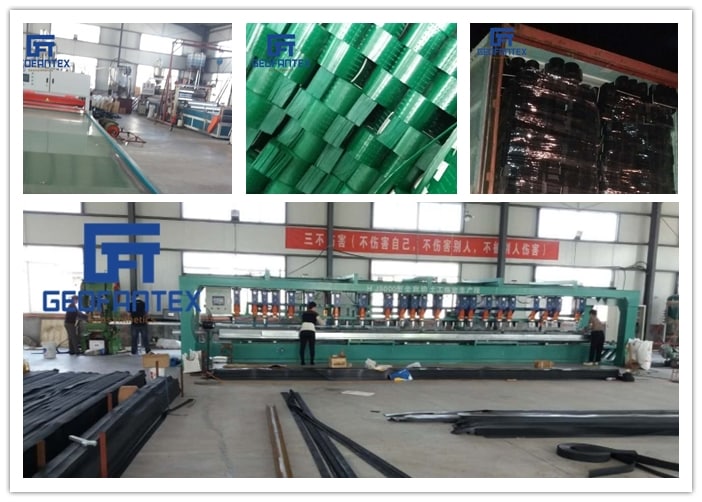

MANUFACTURING QUALITY ASSURANCE

GEOFANTEX has an on-site Manufacturing Quality Assurance Laboratory at the factory. GEOFANTEX maintains a high level of quality and up-to-the-minute results on finished products through a fully equipped, well-staffed, dedicated laboratory existing in each of the manufacturing facilities. Each facility follows the same guidelines for evaluating the quality of GEOFANTEX products and is capable of adapting to market-driven requirements.

A. Objective

The objective of the GEOFANTEX Quality Assurance program is to define the implementation of basic manufacturing quality assurance (MQA) procedures necessary to ensure the consistent production of quality products supplied to the geosynthetic market. Note that at this time, these procedures are limited to Geosynthetics Clay Liner (GCL).

B. Scope

In order to achieve GEOFANTEX’s stated purpose, a rigorous set of minimum standards and an effective test program to assure compliance have been established. These procedures and requirements are frequently reviewed and adjusted to assure compliance with current market demands and/or predetermined project specifications. These procedures assure that raw materials and process parameters are controlled to provide products complying with GEOFANTEX’s pre-defined minimum characteristics.

Geosynthetics Clay Liner (GCL) IDENTIFICATION AND DOCUMENTATION

A. Roll Numbering

Each roll of Geosynthetics Clay Liner (GCL) is assigned a unique roll number. The Quality Assurance Laboratory maintains records documenting the raw materials and resulting product quality information.

B. Approval Procedure

Results for each tested roll of the product are checked against both GEOFANTEX China standards and customer specifications for compliance. The Quality Assurance Laboratory approves those materials that meet these requirements for shipment.

C. Non-Conformance

Material that does not meet GEOFANTEX minimum standards is given a roll number but is rejected and not placed into inventory. The material is identified as scrap and will not be utilized. Material that meets GEOFANTEX minimum standards but does not meet a stricter customer specification is not allocated to that customer but is placed into inventory as GEOFANTEX standard material.

D. Documentation

Individual Quality Assurance Certificates are generated and supplied for each roll of Geosynthetics Clay Liner (GCL) product to include all relevant quality assurance information about the material(s).

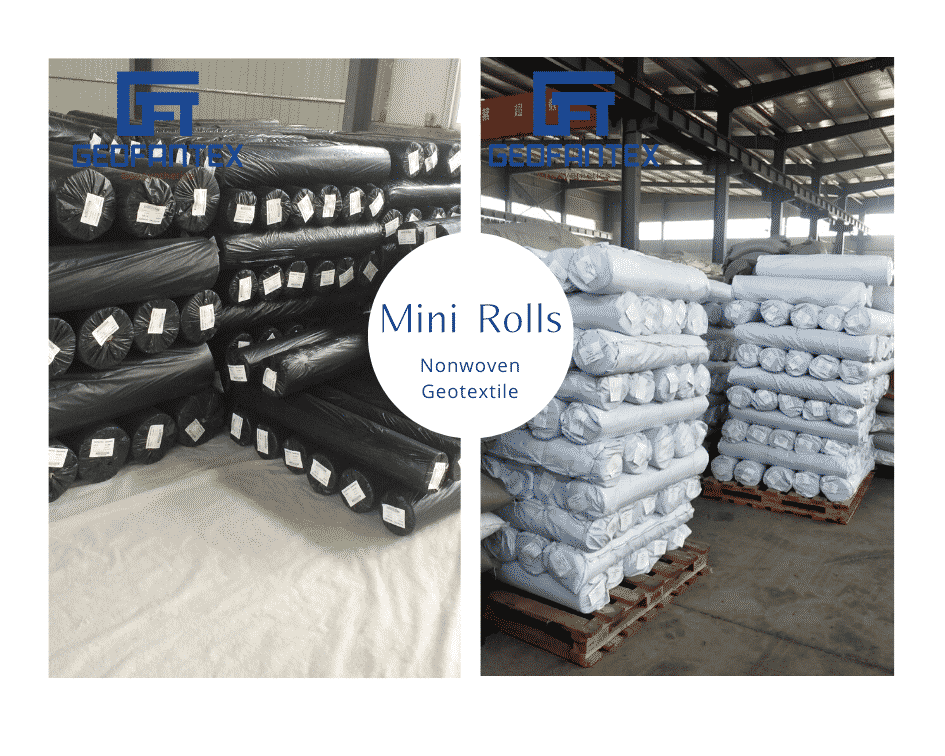

Geofantex Geosynthetics have a series of package and delivery service working procedures. Geofantex Geosynthetics have supplied thousands of containers to Latin America, North America, Southeast Asia, developed countries, and Africa within the past ten years. We provide the package of products with the rolls, pots, bags, sheets, or your requirement in orders. Our company has been committed to supplying high-quality products with reasonable prices and delivery on time. Delivery one 40’HQ within 7 – 10 days. And we have an obligation in increasing loading quantity and make you save the freight costs maximumly. We supply the products by plane, by sea, and by land carriage to any region or any countries of the worldwide, even the door-to-door service.