+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geocell – GeoFanTex

- Brand GeoFanCell® Geocell

- Product origin China

- Delivery time 7-14 days

- Supply capacity 40′ HQ/ 7 Days

Product Details

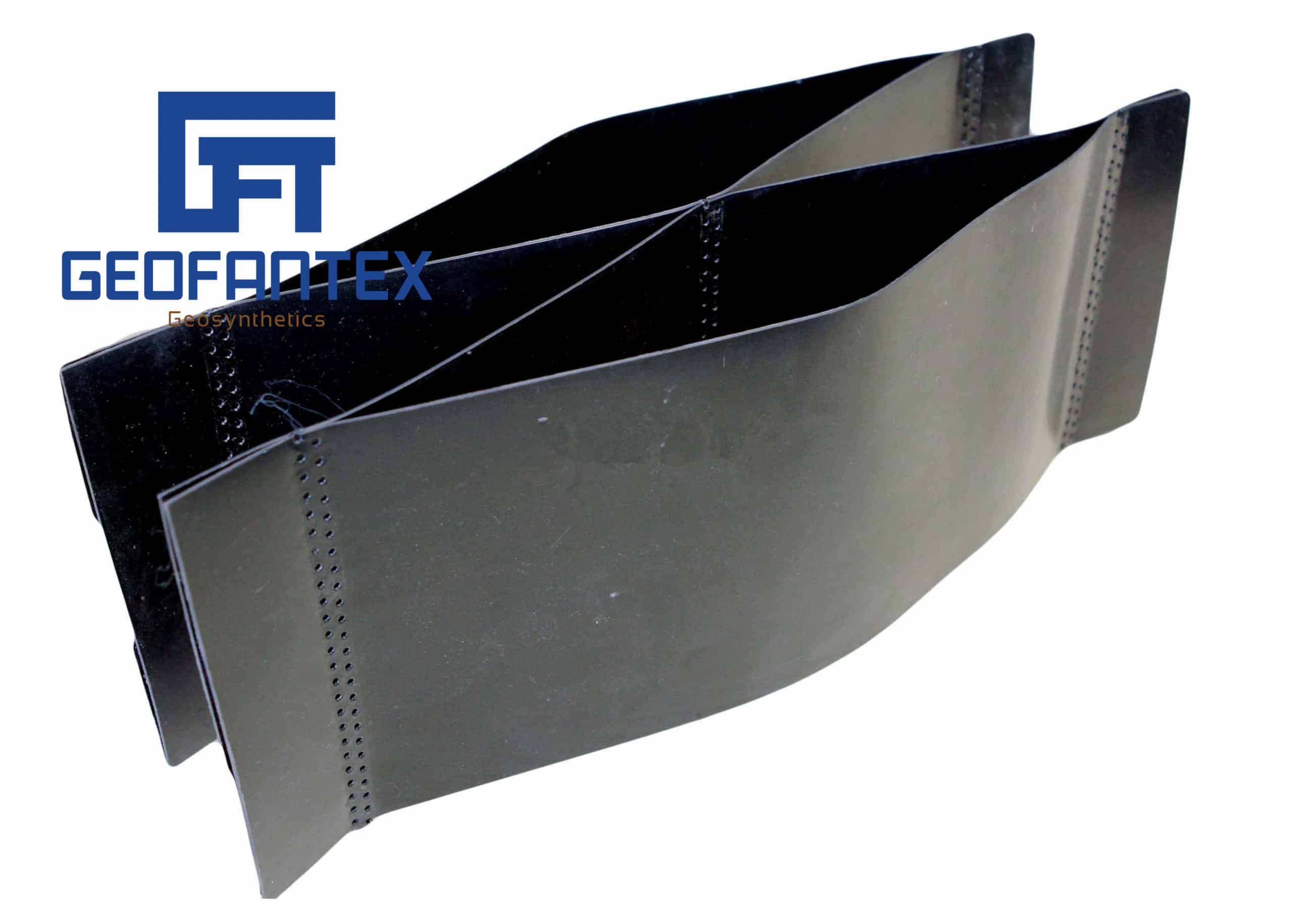

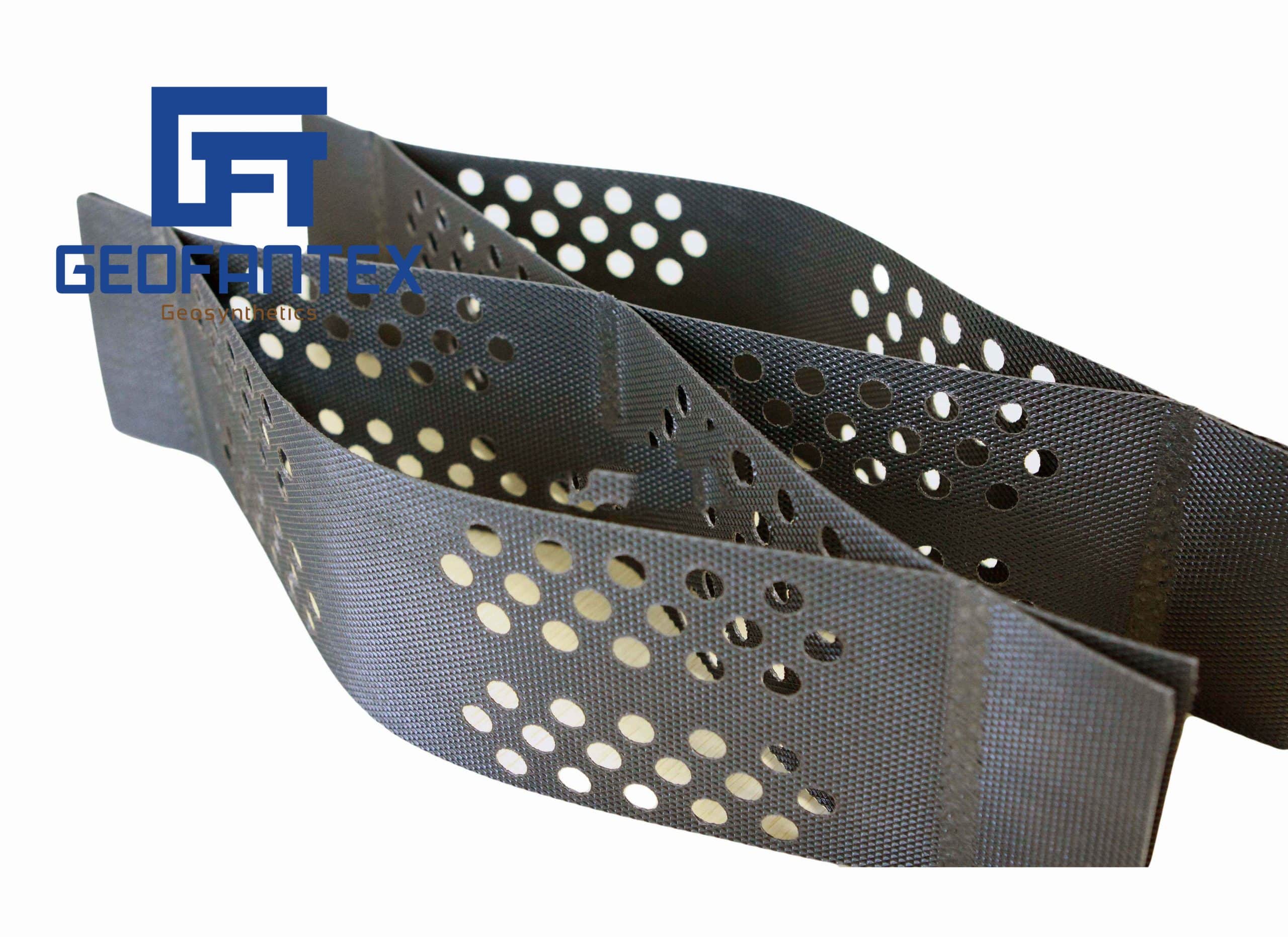

Geocell

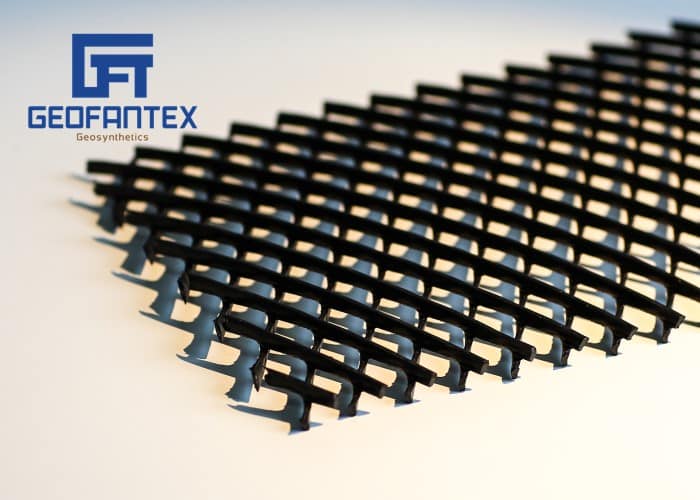

GeoFanCell® Geocell is a three-dimensional mesh cell structure formed by reinforced HDPE sheet material through high-strength welding. It is generally formed by ultrasonic needle welding. Due to engineering needs, some holes are punched in the diaphragm.

Could be manufactured according to your inquiry, MINIMUM ORDER QUANTITY: 20’ft Container

| Properties | Standard | Unit | Specification |

| Cell Depth | mm | 50 / 75 / 100 / 150 / 200 | |

| Weld Spacing | mm | 330 / 356 / 400 / 450 / 460 / 500 / 550 / 600 / 660 / 710 / 800 | |

| Unexpanded Panel Size | m | 3.19 × 0.120 × Panel Depth | |

| Expanded Panel Size | m | 2.44 × 6.1 | |

| Sheet Thickness | ASTM D 5199 | mm | 1.0 (+/-0.1) |

| Color | Black / Green | ||

| Polymer | Polyethylene | ||

| Density | ASTM D 1505 | g/cm3 | 0.939 – 0.960 |

| Carbon Black Content | % | Min 2% | |

| Seam Strength AS 3706.6(modified) | N/10cm | ≥1,000 |

Applications of Geocell

- Used for stabilizing subgrades of highways and railways.

- Used for load-bearing dikes and shallow rivers.

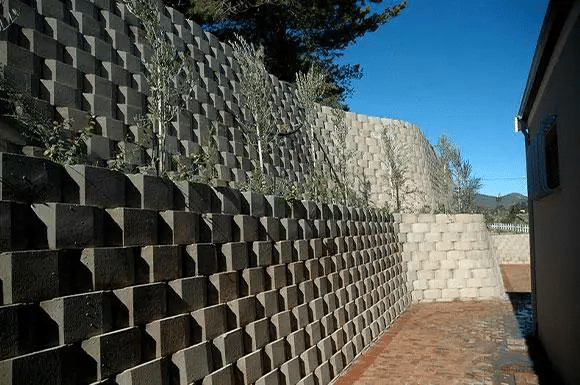

- Combined retaining wall used to prevent landslides and gravity load.

- When soft foundations are encountered, the use of geocells can greatly reduce the labor intensity of construction, reduce the thickness of the roadway, the construction speed is fast, the performance is good, and the project cost is greatly reduced.

- Deal with half-filled and half-cut subgrade: When building an embankment on a slope where the natural slope of the ground is steeper than 1:5, the embankment base should be dug steps, and the width of the steps should not be less than 1M. When the road is built or rebuilt in phases and the road is widened, the junction of the new and old subgrade fill slopes should be opened. For digging steps, the width of the high-grade highway steps is generally 2M, and the geocell is laid on the horizontal surface of each step, and the geocell’s own elevation confinement reinforcement effect is used to better solve the problem of uneven settlement.

- Roadbed in sandy areas: Low embankments should be the main roadbed in sandy areas, and the filling height is generally not less than 0.3M. Due to the professional requirements for low roadbeds and heavy loads in sandy areas, the use of geocells can limit loose fillers. The limited height ensures that the roadbed has high rigidity and strength to withstand the load stress of large vehicles.

- Filling and reinforcement of the subgrade behind abutment: The use of geocells can better achieve the purpose of reinforcement of the abutment back. Sufficient friction can be generated between the geocell and the filler, which can effectively reduce the uneven settlement between the subgrade and the structure, and finally can effectively alleviate the “abutment jump”. Early impact damage to the bridge deck caused by the “car” disease.

- Roadbed in permafrost regions: The minimum fill height should be reached in the construction of filled roadbeds in permafrost regions to prevent the occurrence of tumbling or the lowering of the upper limit of the frozen layer, resulting in excessive settlement of the embankment. The unique vertical reinforcement effect of the geocell and the effective implementation of the overall confinement can ensure the minimum fill height in some special sections to the greatest extent, and make the fill have high-quality strength and rigidity.

- Treatment of collapsible loess roadbed: When expressways and first-class highways pass through collapsible loess and loess sections with good compressibility, or when the allowable bearing capacity of the foundation of a high embankment is lower than the pressure of the combined load of vehicles and the self-weight of the embankment, the subgrade should also be adjusted according to the bearing capacity requirements. After processing, the superiority of the geocell is undoubtedly evident.

- Saline soil and expansive soil: Reinforcement measures are adopted for highways, first-class highways, shoulders and slopes built with saline soil and expansive soil. The facade reinforcement effect of the cell is the most excellent one of all reinforcement materials, and it has excellent corrosion resistance. It can fully meet the requirements of constructing highways in saline soil and expansive soil.

Geofantex Geosynthetics have to make a series of guarantee for our products both plant processing and selling out to our customers. The selling to you is the first step, the service and guarantee is our task. Geofantex Geosynthetics have an ISO Certificate to guarantee the raw material, the product processing, and the end product. From receiving your order to replacement and installation of the products, we have solved the problems in time if you need, whatever the quality and technics guideline or suggestions. Our company has been committed to supplying high-quality products with reasonable price and delivery in time.

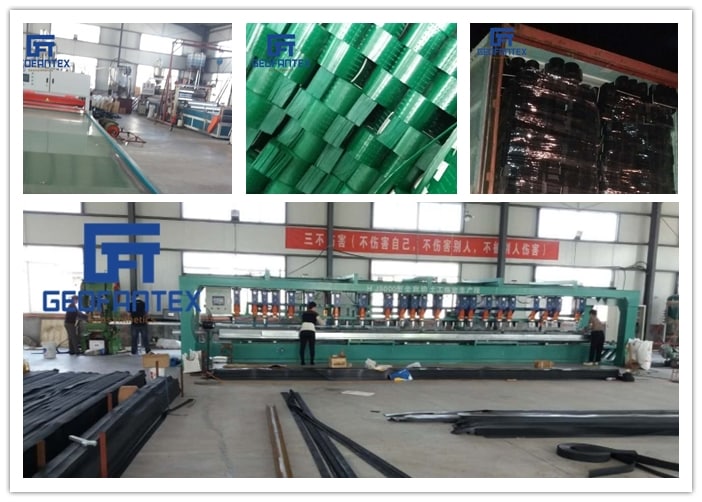

GEOFANTEX has an on-site Manufacturing Quality Assurance Laboratory at the factory. GEOFANTEX maintains a high level of quality and up-to-the-minute results on finished products through a fully equipped, well-staffed, dedicated laboratory existing in each of the manufacturing facilities. Each facility follows the same guidelines for evaluating the quality of GEOFANTEX products and is capable of adapting to market-driven requirements.

A. Objective

The objective of the GEOFANTEX Quality Assurance program is to define the implementation of basic manufacturing quality assurance (MQA) procedures necessary to ensure the consistent production of quality products supplied to the geosynthetic market. Note that at this time, these procedures are limited to Geocell.

B. Scope

In order to achieve GEOFANTEX’s stated purpose, a rigorous set of minimum standards and an effective test program to assure compliance have been established. These procedures and requirements are frequently reviewed and adjusted to assure compliance with current market demands and/or predetermined project specifications. These procedures assure that raw materials and process parameters are controlled to provide products complying with GEOFANTEX’s pre-defined minimum characteristics.

Geocell PRODUCT IDENTIFICATION AND DOCUMENTATION

A. Roll Numbering

Each roll of Geocell (GeoFanTex® Geocell) is assigned a unique roll number. The Quality Assurance Laboratory maintains records documenting the raw materials and resulting product quality information.

B. Approval Procedure

Results for each tested roll of the product are checked against both GEOFANTEX China standard and customer specifications for compliance. The Quality Assurance Laboratory approves those materials that meet these requirements for shipment.

C. Non-Conformance

Material that does not meet GEOFANTEX minimum standards is given a roll number but is rejected and not placed into inventory. The material is identified as scrap and will not be utilized. Material that meets GEOFANTEX minimum standards but does not meet a stricter customer specification is not allocated to that customer but is placed into inventory as GEOFANTEX standard material.

D. Documentation

Individual Quality Assurance Certificates are generated and supplied for each roll of Geocell product to include all relevant quality assurance information about the material(s).

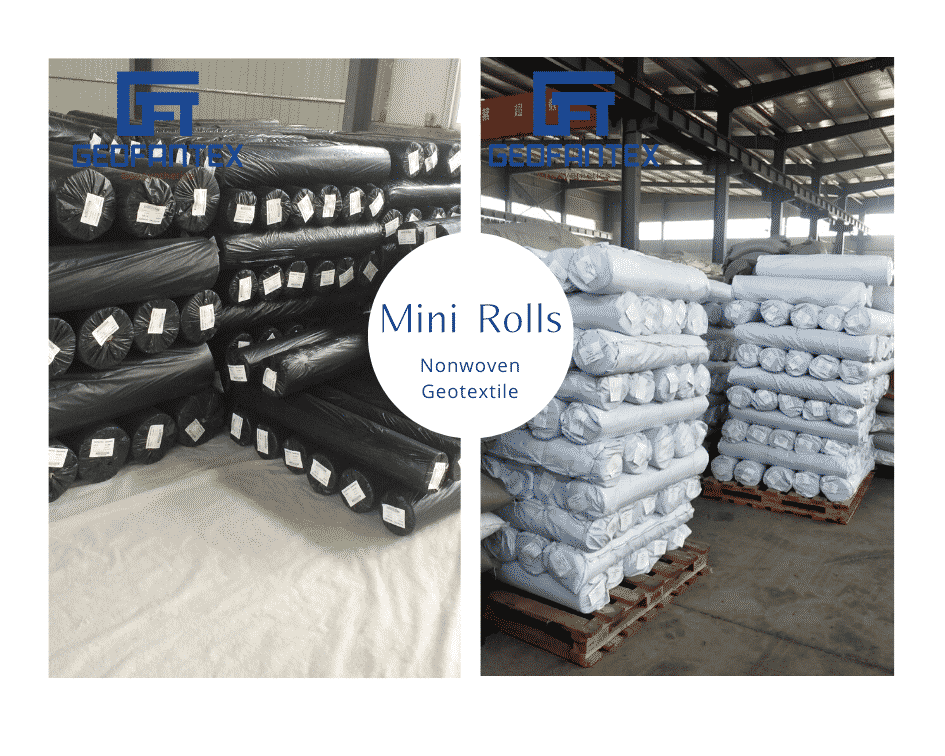

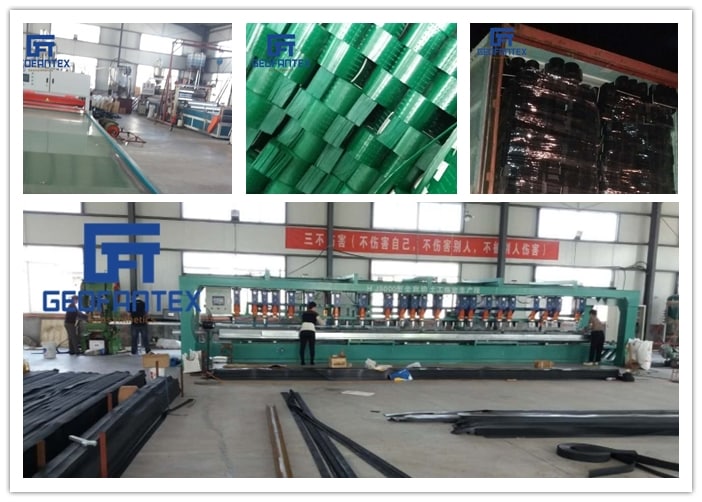

Geofantex Geosynthetics have a series of package and delivery service working procedures. Geofantex Geosynthetics have supplied thousands of containers to Latin America, North America, Southeast Asia, developed countries, and Africa within the past ten years. We provide the package of products with the rolls, pots, bags, sheets, or your requirement in orders. Our company has been committed to supplying high-quality products with reasonable price and delivery in time. Delivery one 40’HQ within 7 – 10 days. And we have an obligation in increasing loading quantity and make you save the freight costs maximumly. We supply the products by plane, by sea and land carriage to any regions or any countries of the worldwide, even the door-to-door service.

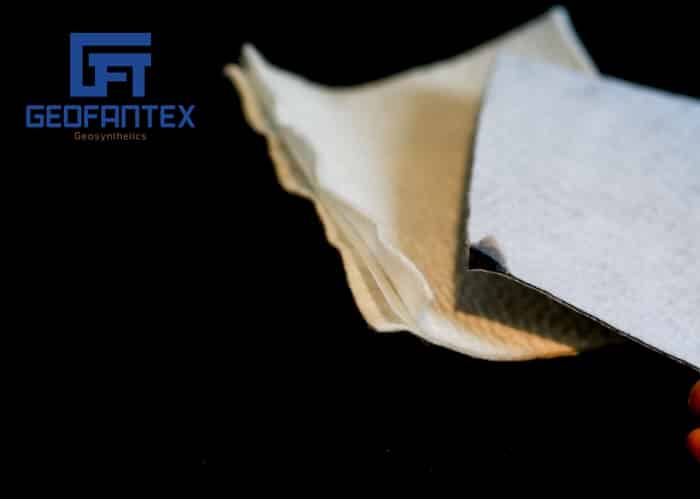

| SEPARATION | REINFORCEMENT | FILTRATION | DRAINAGE | WATERPROOF | PREVENTION | POLLUTION PREVENTION | PROTECTION | CONSOLIDATE | |

| GEOTEXTILE | √ | √ | √ | √ | √ | √ | |||

| GEOMEMBRANE | √ | √ | √ | ||||||

| GEOGRID | √ | √ | |||||||

| GEONET | √ | ||||||||

| GEOTUBE | √ | ||||||||

| GEOCELL | √ | √ | |||||||

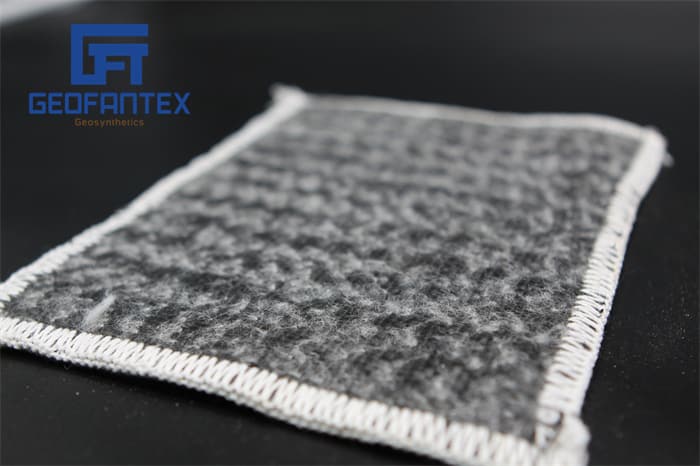

| GCL | √ | √ | |||||||

| GEOCOMPOSITE | √ | √ | √ | √ | √ | √ | √ | ||

| GEOCONCRETE BLANKET | √ | √ | √ | ||||||

| Drainage Board B | √ | √ | √ | √ | |||||

| Storage and Drainage Board | √ | √ | √ | √ | |||||

| Grass Paver | √ | √ | √ | √ | √ | √ | √ | ||

| Macmat | √ | √ | √ | √ | √ | √ | √ | ||

| GeoFanTex®GD 2L | √ | √ | √ | √ | √ | √ | |||

| GeoFanPipe® FP | √ | ||||||||

| GeoFanDrain® BC | √ | √ | √ | ||||||

| GeoFanPipe® DCP | √ | √ | |||||||

| GeoFanTRM® Geomantles | √ | √ | √ | √ | √ |

General Installation Guidelines

GeoFanTex geocells are honeycomb structures made of HDPE strips, primarily used for foundation reinforcement, slope protection, and soil erosion control. The installation process involves multiple steps, each closely linked and significantly impacting project quality.

Step 1: Subgrade Preparation

Remove weak/compressible native soil and replace with compacted fill; shape, proof-roll, and trim the subgrade to ensure flatness and density.

Step 2: Base Layer Placement

Lay the specified geotextile separation layer; place granular base material and compact to 95% Standard Proctor Dry Density; wrap free-draining base with non-woven geotextile.

Step 3: Footing Section Installation

Three options available: Insert stretcher bars for positioning and filling; fit over a stretcher frame (remove after filling); unroll and anchor with stakes.

Step 4: Drainage, Fill Placement & Compaction

Install drainage pipes (gradient ≥1%); overfill with 50mm granular material, compact to 95% density (avoid over-vibration to prevent panel lifting); remove excess material to expose cell walls after compaction.

Step 5: Wall Section Installation

Position unrolled geocell wall sections with stretcher tools/stakes; align and interleaf adjacent sections, connect with wall keys; overfill 50mm with specified material and level.

Step 6: Structural Layout & Reinforcement

Fill outer cells with topsoil (use temporary planks during general filling, remove later), compact with walk-behind equipment; maintain setback and vertical alignment for subsequent layers, adjust 15mm setback for curved walls if misaligned; install geosynthetic reinforcement as required.

Certificate

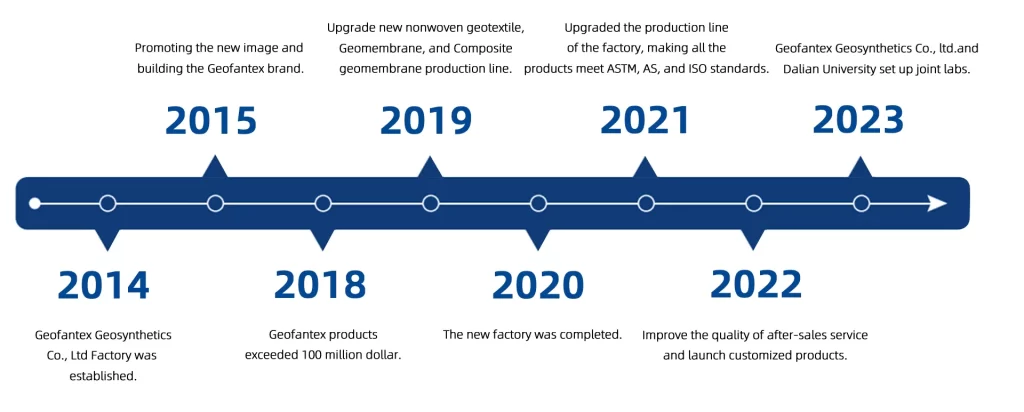

Development history of the company

Company Profile

Geofantex Geosynthetics Co., Ltd. is based in Dalian, a beautiful coastal city known for its excellent location and good transportation. Founded in 2014 with a registered capital of 5 million yuan, the company operates from an industrial park in Jinan, Shandong, covering over 50 acres. It features a modern office, advanced production equipment, and a skilled team in technical and management roles.

Geofantex has achieved ISO9001 and ISO14001 certifications and adheres to national standards to ensure product quality. Since its inception, the company has adopted advanced technologies and equipment, exporting products to regions like Australia, Canada, and Southeast Asia. Its export sales have reached significant figures, and customer feedback highlights our products’ stability, reliability, and cost-effectiveness.

The company leverages its innovative capabilities and market advantages, aiming to become a leading enterprise supported by national policies. Committed to “quality first” and “reputation first,” it emphasizes a people-oriented approach and values integrity, unity, and hard work. Geofantex seeks to collaborate with various engineering units to contribute to infrastructure development.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)