+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Retaining walls play a crucial role in managing soil and preventing erosion in various landscaping and construction projects. One essential material that enhances the effectiveness and durability of retaining walls is geotextile fabric. This specially designed fabric offers superior drainage, filtration, and reinforcement, making it an integral part of modern retaining wall systems. In this article, we’ll explore how geotextile fabric benefits retaining walls and address common questions related to its usage.

Why should geotextile fabric be used in retaining walls, and how does it enhance soil stability, drainage, and wall durability?

Geotextile fabric is essential in retaining wall construction because it improves soil stability, manages water flow, and extends the lifespan of the wall. It acts as a permeable barrier between backfill soil and drainage layers, preventing soil particles from clogging the drainage system and reducing hydrostatic pressure behind the wall. Key benefits include:

- Improved Drainage: Allows water to pass while filtering fine soil particles, preventing water buildup.

- Reduced Hydrostatic Pressure: Minimizes water pressure that can compromise structural integrity.

- Soil Layer Separation: Maintains consistent load-bearing capacity by keeping different soil types separate.

- Enhanced Wall Stability: When combined with geogrids, it provides additional reinforcement.

- Erosion Prevention: Protects slopes and backfill from soil displacement, maintaining landscape and structural integrity.

Using geotextile fabric ensures that retaining walls remain stable, functional, and durable over time, making it a standard practice in both residential and commercial projects.

What type of landscape fabric is best for retaining walls?

| Type | Material | Durability | Permeability | Best Use | Pros | Cons |

|---|---|---|---|---|---|---|

| Woven Landscape Fabric | Polypropylene/Polyester | High | Moderate | Heavy-duty retaining walls | Very durable, UV resistant | Less flexible, expensive |

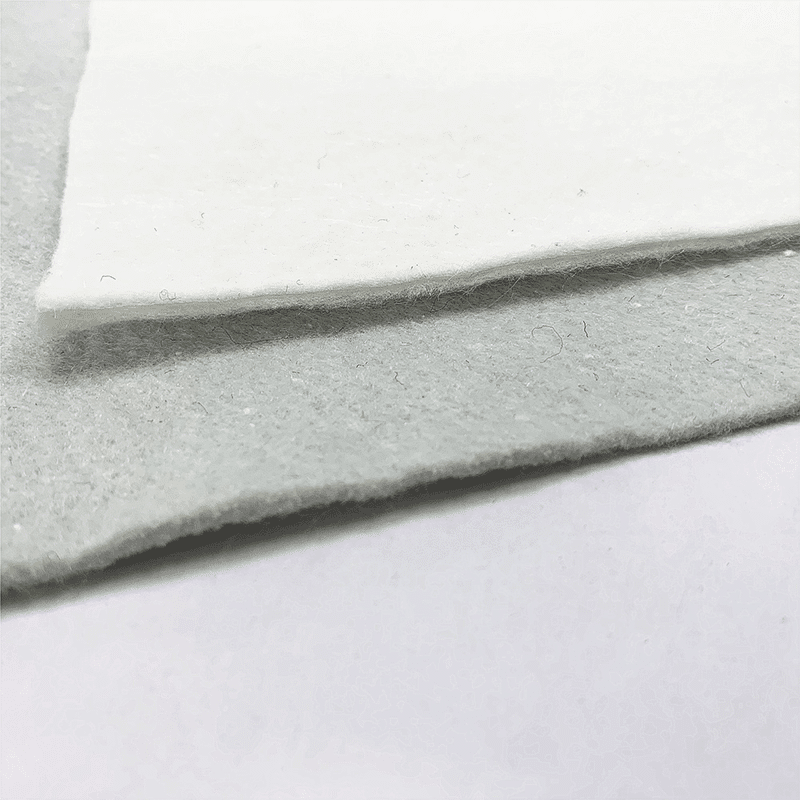

| Non-Woven Geotextile | Bonded synthetic fibers | Moderate | High | Soil separation, drainage | Affordable, excellent drainage | Less durable, tears easily |

| Perforated Landscape Fabric | Plastic-based | Moderate | High | Light to moderate loads | Easy installation, cost-effective | Not for heavy loads |

| Spun-Bonded Landscape Fabric | Bonded synthetic fibers | Moderate | Moderate | Low-load retaining walls | Good durability | Faster degradation possible |

¿Cuáles son los pasos clave para instalar correctamente geotextil en muros de contención?

Para asegurar que el geotextil cumpla su función de drenaje, separación y refuerzo en muros de contención, sigue estos pasos esenciales:

- Preparar el terreno: Limpia y nivela la zona detrás del muro, eliminando piedras u objetos punzantes que puedan dañar el geotextil.

- Instalar la capa de drenaje: Coloca grava o piedra triturada compactada como base para facilitar la evacuación del agua.

- Colocar el geotextil: Extiende la tela sobre la capa de drenaje, asegurándote de que quede plana y con solapes de al menos 30 cm entre secciones.

- Fijación del material: Usa grapas, estacas o anclajes para mantener el geotextil en su lugar durante el relleno.

- Relleno por capas: Añade el material de relleno (grava o tierra) en capas, compactando suavemente para no dañar la tela.

- Integración de drenaje adicional: Si es necesario, instala tuberías perforadas detrás del muro para mejorar el flujo de agua y reducir presión hidrostática.

- Finalización: Completa el relleno y aplica protección superficial, como vegetación o coberturas de erosión, para mantener la estabilidad.

Siguiendo estos pasos, el geotextil garantiza mayor durabilidad, estabilidad y control de erosión, optimizando el desempeño del muro de contención a largo plazo.

When to use geotextile fabric?

Geotextile fabric should be used whenever soil stability, erosion control, or proper drainage is essential to the success and longevity of a project. In retaining wall construction, it is especially valuable in situations where water management and soil separation are critical to preventing structural damage.

- For Retaining Walls: Install geotextile fabric when the wall will be exposed to significant water flow or heavy rainfall. This helps prevent soil from washing into drainage systems and reduces hydrostatic pressure.

- For Erosion-Prone Areas: Use geotextiles on slopes, embankments, or riverbanks to keep soil in place while allowing water to pass through, minimizing washouts.

- For Soil Stabilization: When working on driveways, roads, or paths, geotextiles act as a stable base layer, preventing rutting and mixing of soil layers under repeated loads.

- For Drainage Projects: In French drains, behind retaining walls, or in agricultural applications, non-woven geotextiles improve water flow while preventing clogging by soil particles.

Best Practice Tip: Always match the fabric type to the application—woven geotextiles for high strength and load-bearing uses, and non-woven geotextiles for superior filtration and drainage. Choosing the right fabric and installing it correctly ensures maximum performance, whether the goal is to strengthen soil, manage water, or protect against erosion.

Geotextile fabric is a key material for ensuring the stability and longevity of retaining walls. Its ability to filter water while reinforcing soil makes it an essential component in preventing erosion and water-related issues. Whether you’re building a small garden retaining wall or a larger structure, using the right type of geotextile fabric and applying it correctly can make a significant difference in the wall’s performance.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)