+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geotextiles are synthetic fabrics used in civil engineering and construction to improve soil stability, drainage, and erosion control. They play a critical role in highways, embankments, retaining walls, and other infrastructure projects. Understanding the different types of geotextiles helps engineers and contractors choose the right material for each application.

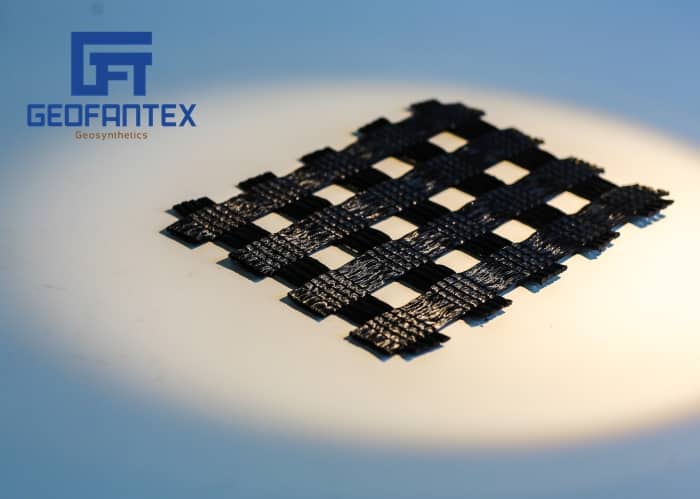

Woven Geotextiles

Woven geotextiles are made by interlacing synthetic fibers such as polyester or polypropylene in a weaving process. This construction gives them high tensile strength, making them ideal for soil reinforcement and load-bearing applications.

Applications of woven geotextiles include:

- Reinforcing roads, highways, and airport runways

- Stabilizing embankments and retaining walls

- Separating different soil layers to prevent contamination

- Erosion control in slopes and riverbanks

The high strength and durability of woven geotextiles make them perfect for projects that require long-term structural support.

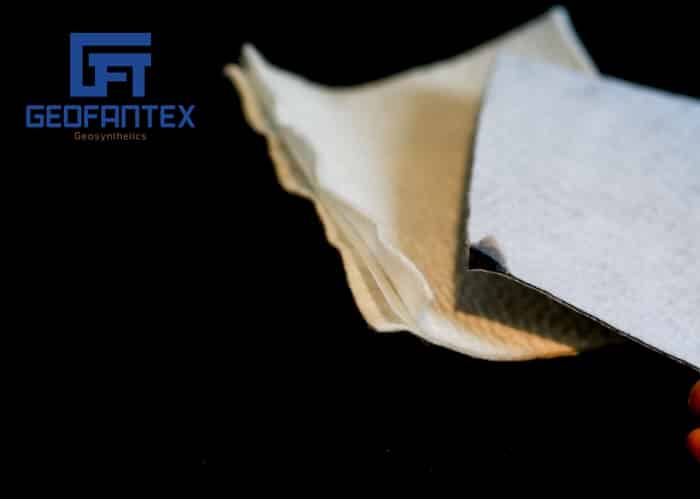

Non-Woven Geotextiles

Non-woven geotextiles are manufactured by bonding fibers together using heat, chemical, or mechanical processes rather than weaving. They are mainly used for filtration, drainage, and protection applications.

Common uses:

- Subsurface drainage systems

- Soil filtration layers

- Protecting geomembranes in landfill liners

Knitted and Other Specialty Geotextiles

Knitted geotextiles and other specialty fabrics are designed for specific applications, including erosion control mats and geogrids. They often combine properties of woven and non-woven fabrics to meet unique engineering requirements.

Choosing the right type of geotextile is crucial for the success of any civil engineering project. Among all types, woven geotextiles stand out for their exceptional tensile strength, making them a preferred choice for reinforcement and heavy-duty applications.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)