+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

What is Geosynthetics?

What is Geosynthetics

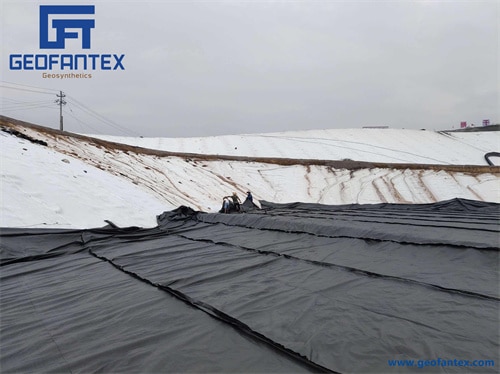

Geosynthetics are a wide range of products used to contain fluids and prevent contamination in a variety of applications. These materials include geotextile fabric and non-woven geotextiles. These fabrics are often used for pipeline linings, water reservoir covers, and other solid or liquid-storage facilities.

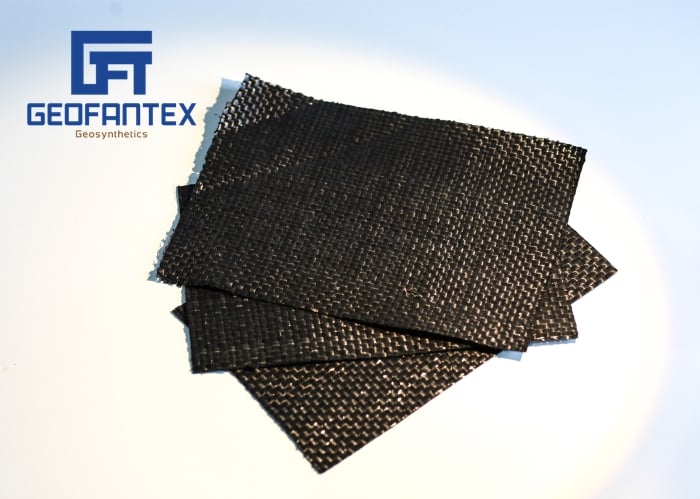

Geotextile Material

Geosynthetics are a diverse class of materials used in geotechnical engineering. They are flexible, planar materials that work with rock, soil, and other geotechnical materials. These materials can be used as the sole component of a structure or man-made project, or as part of a complex system.

Geotextiles are made of fibers, yarns, or planar textile structures. These yarns may be continuous filaments or stapled or fibrillated. The type of yarn used will determine the geotextile’s properties. Fibers may be woven or knitted in flat or textured patterns. They can also be extruded as a tubular sheet and then cut to size in a machine direction. Added textured layers are sometimes added to increase strength and thickness.

Geotextile material is made from synthetic fibers, and the vast majority is woven. Geotextiles are made by interweaving threads, and they are typically 50 to 150 meters long. The fibers are bonded by heat, resin, or needle punching. Geotextiles are primarily used for soil reinforcement and separation, but can also help with filtration and drainage.

Geosynthetics

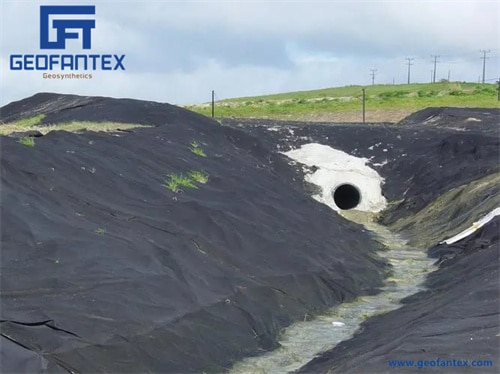

Geosynthetics are materials that are designed to provide a particular function. These materials are usually flexible, and their primary functions include separation, reinforcement, and control of deformation. In geotechnical engineering, they are commonly used in the construction of railroad bases and unpaved roads. Some groups suggest that geosynthetics can have additional functions.

Geosynthetics are typically manufactured in controlled environments. Many factories are ISO 9000 certified and run in-house quality programs. Geosynthetics must be designed to meet specific performance standards, and the appropriate additives should be added to ensure long-term performance. These guidelines should be followed carefully to prevent contamination and degradation of the geosynthetics.

Most geosynthetics are designed to interact with the soil particles to provide adequate strength and resilience. They also prevent the soil from shifting, which is important for foundation support. Geogrids are an excellent option for slope stabilization and erosion control because they cost less per square foot than other solutions and work well in a variety of settings.

Geotextile Fabric

A geosynthetic material is a polymeric material used in the construction of civil engineering structures. Its main functions include filtration, drainage, reinforcement, protection, and waterproofing. Geotextiles are often used for pavements. The use of geotextiles is increasing as people become more aware of their benefits and use them in construction projects.

There are several types of geosynthetics, including geotextile fabrics and geofoam. Both types can be used for different applications. For example, geofoam and geocells are used in the construction of roads. They can also be used for filtration in the soil.

Geotextile fabric is the most widely used geosynthetic material and is used to construct road and railway infrastructures. However, it is important to understand its different functions before applying it. There are three main categories: passive, active, and smart. The passive type plays a passive role and provides the desired effect, whereas the active type creates change in its environment.

Non-woven Geotextile Fabric

A non-woven geotextile is a flexible fabric that performs separation, filtration, and drainage functions. These materials are lightweight, pliable, and resistant to tearing, making them an ideal choice for various applications. These materials are often used as covers or as cushioning for geomembranes.

Non-woven geotextiles are usually made of polymers. These materials can be produced using two different types of processes. The first technique, known as melt extrusion, involves drawing polymers through spinnerets. Afterward, the molten polymer is extruded along a filament axis. This method improves molecular orientation. The second method, known as multifilament spinning, involves drawing short filaments (two to ten centimeters) together to form a yarn.

Nonwoven geotextile fabrics are useful for a variety of geotextile applications, including road construction. They also help to prevent leaching and can prevent fine soil particles from draining. They can also serve as a barrier between adjacent layers of soil, preventing soil contaminants from mixing.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)