+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

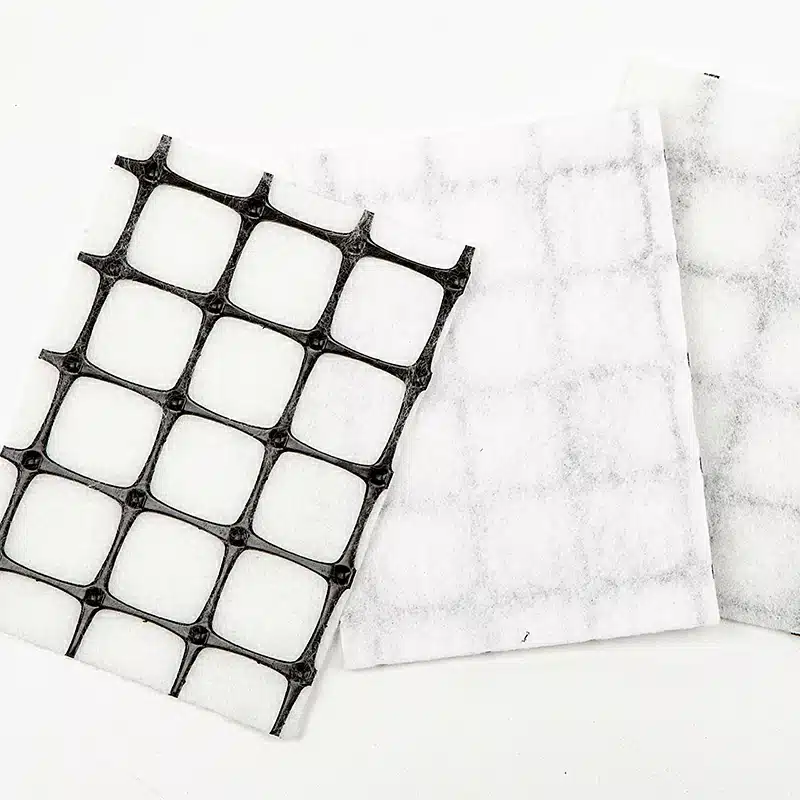

The first sentence must contain the keyword, so here it is: In modern civil and environmental engineering, the geocomposito has become a critical geosynthetic solution for improving drainage, separation, and reinforcement performance. Engineers often compare it with other materials such as nonwoven geotextiles to determine the most suitable system for long-term performance.

Railway Engineering Application

In railway infrastructure, the advantages of the geocomposito are especially clear. During the Torino–Milano High-Speed Rail expansion in Italy, engineers faced excessive moisture retention in a clay-based subgrade that weakened ballast stability. To solve this, they installed a geonet–geotextile composite layer similar to the drainage geocomposites used in railway foundations, which efficiently redirected lateral water flow. After one rainy season, pore-water pressure dropped significantly, track stiffness improved, and maintenance intervals were extended. The system also prevented fine particles from contaminating the ballast layer, and the case has since been referenced in multiple European rail engineering discussions.

Environmental Engineering Application

In environmental containment systems, the geocomposito is widely adopted for managing leachate. At a major municipal landfill in São Paulo, Brazil, high rainfall and organic waste produced large volumes of leachate that strained the existing drainage system. Engineers replaced the traditional gravel drainage layer with a drainage geocomposite installed directly above the geomembrane, similar to products used in landfill lining systems. After implementation, the lateral flow rate improved, the overall liner thickness was reduced, and operational costs decreased due to fewer material transport requirements. This application became a benchmark in sustainable landfill design in the region.

Road and Embankment Engineering Application

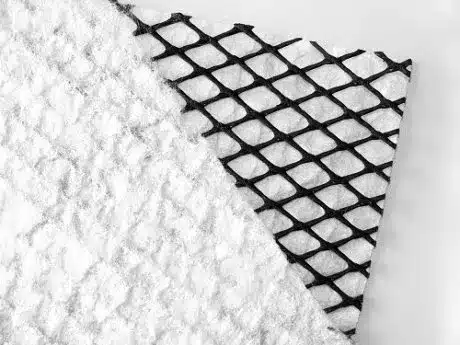

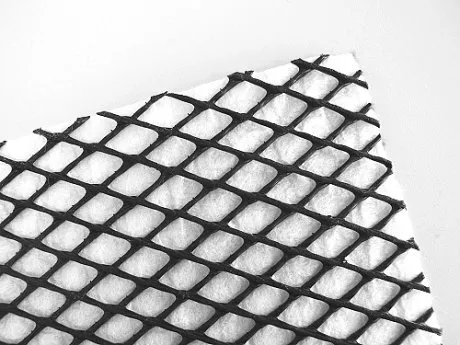

In road and embankment reinforcement works, composite reinforcement materials provide a reliable solution for soft-soil deformation. During a coastal expressway rehabilitation project in Japan, the combination of marine clay foundations and typhoon-related water loads created risks of uneven settlement and slope instability. The project team applied a high-strength geogrid bonded with nonwoven geotextile similar to the reinforcement geogrids used in soft soil treatment, which offered enhanced tensile restraint and separation capability. Monitoring showed a significant reduction in differential settlement and improved construction efficiency, and the project has been widely cited in Japanese geotechnical engineering circles.

In conclusion, the geocomposito consistently delivers structural, hydraulic, and economic benefits across a range of engineering scenarios. As more field-proven cases continue to validate its performance, this composite material is becoming an essential component in modern infrastructure design and development. For additional technical references, engineers often review related geosynthetic solutions to optimize system selection during design.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)