+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

LLDPE Geomembranes – GeoFanTex

- Brand GeoFanMeb® LLD

- Product origin China

- Delivery time 7-14 Days

- Supply capacity 40′ HQ/ 7 Days

Product Details

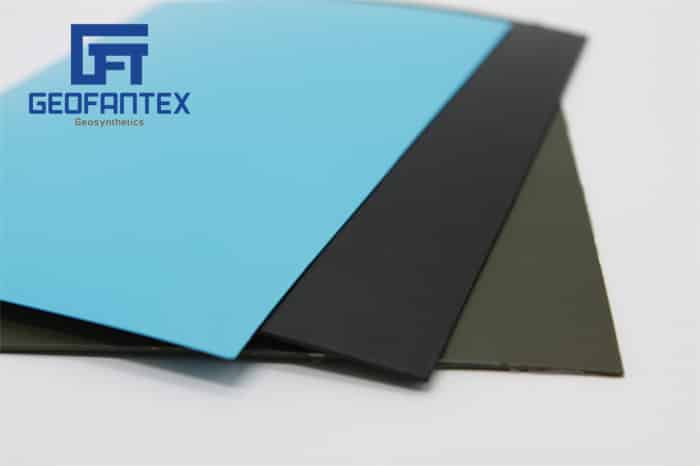

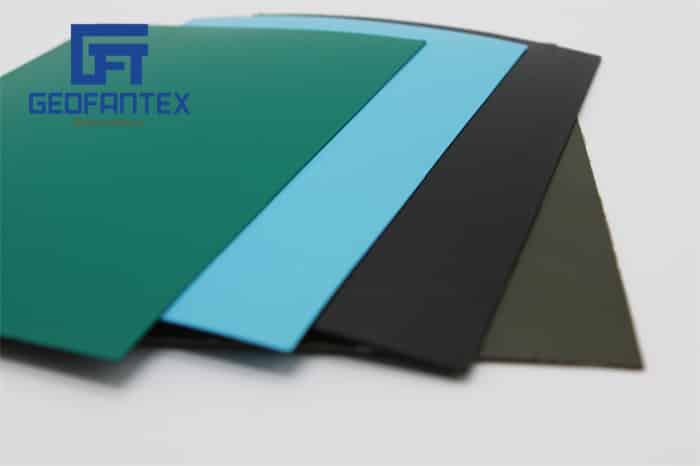

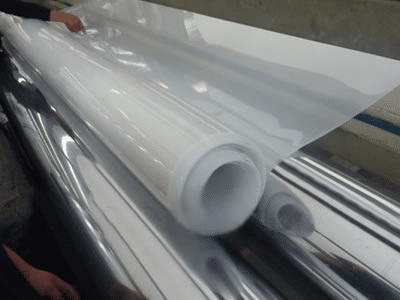

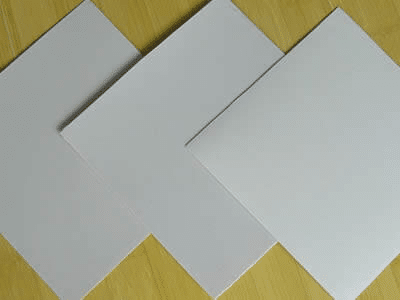

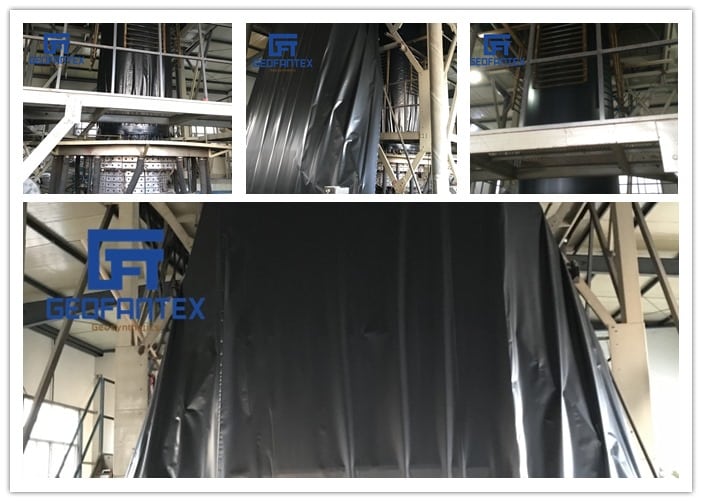

LLDPE Smooth Geomembrane is made from Linear low-density polyethylene film liner. Both sides of the Geomembrane are smooth. LLDPE Smooth Geomembrane is manufactured by the technology of coextrusion blown triple layer.

The functions of the LLDPE Smooth Geomembrane are excellent physical and mechanical properties, high tearing resistance, and waterproof performance.

LLDPE Geomembrane Manufacturer

(* Geofantex Geosynthetics can produce GeoFanMeb® LLD according to your requirement in constructions, MINIMUM ORDER QUANTITY: 20’ft Container)

| Properties | Unit | Standard | LLD 050 | LLD 075 | LLD 100 | LLD 150 | LLD 200 | LLD 250 |

| Thickness | mm | ASTM D 5199 | 0.50 | 0.75 | 1.00 | 1.50 | 2.00 | 2.50 |

| Density | g/cc | ASTM D 1505 | 0.939 | 0.939 | 0.939 | 0.939 | 0.939 | 0.939 |

| Tensile Properties | ASTM D 6693,TypeIV | |||||||

| Strength at Break | N/mm | Dumbell, 2ipm | 13 | 20 | 27 | 40 | 53 | 66 |

| Elongation at Break | G.L. 2.0 in (51mm) | 800 | 800 | 800 | 800 | 800 | 800 | |

| 2% Modulus (max) | N/mm | ASTM D 5323 | 210 | 370 | 420 | 630 | 840 | 1050 |

| Tear Resistance | N | ASTM D 1004 | 50 | 70 | 100 | 150 | 200 | 250 |

| Puncture Resistance | N | ASTM D 4833 | 120 | 190 | 250 | 370 | 500 | 620 |

| Axi-Symmetric Break Resistance Strain | % | ASTM D 5617 | 30 | 30 | 30 | 30 | 30 | 30 |

| Carbon Black Content | % | ASTM D 1603*/4218 | 2 | 2 | 2 | 2 | 2 | 2 |

| Carbon Black Dispersion | ASTM D 5596 | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | |

| Oxidative Induction Time | min | ASTM D 3895, 200℃, 1 atm | 100 | 100 | 100 | 100 | 100 | 100 |

| Oven Aging at 85℃ | ASTM D 5721 | |||||||

| Standard OIT, Retained after 90 Days | % | ASTM D 3895 | 35 | 35 | 35 | 35 | 35 | 35 |

| UV Resistance (at 1600 hours) | % | ASTM D 5885 | 35 | 35 | 35 | 35 | 35 | 35 |

LLDPE geomembrane Features

- High anti-seepage coefficient: LLDPE geomembrane has an anti-seepage effect that ordinary waterproof materials can’t match. LLDPE geomembrane has high tensile mechanical resistance, and its excellent elasticity and deformability make it very suitable for expansion or contraction of the base surface, which can be effective To overcome the uneven settlement of the base surface, the water vapor permeability coefficient K<=1.0*/c cm2.

- Chemical stability: Geomembrane has excellent chemical stability and is widely used in sewage treatment, chemical reaction tanks, and landfills. High and low-temperature resistance, asphalt, oil and tar resistance, acid, alkali, salt, and more than 80 kinds of strong acid and alkali chemical media corrosion.

- Anti-aging performance: LLDPE geomembrane has excellent anti-aging, anti-ultraviolet, and anti-decomposition capabilities, and can be used in the open. The service life of the material is 50-70 years, which provides a good material guarantee for environmental seepage prevention.

- Resistance to plant roots: LLDPE geomembrane has excellent puncture resistance and can resist most plant roots

- High mechanical strength-geomembrane has good mechanical strength, tensile strength at break 28MP, elongation at break 700%

- Low-cost and high efficiency: LLDPE geomembrane adopts new technology to improve the anti-seepage effect, but the production process is more scientific and fast, so the production cost is lower than traditional waterproof materials. According to actual calculations, general engineering using LLDPE geomembrane should be saved Costs around 50%

- Fast construction speed: geomembrane has high flexibility and has a variety of specifications and multiple laying forms to meet the anti-seepage requirements of different projects. It adopts hot-melt welding, high weld strength, convenient construction, fast and healthy.

- Environmental protection and non-toxic: The materials used in the geomembrane are all non-toxic and environmentally friendly materials. The anti-seepage principle is ordinary physical changes and does not produce any harmful substances. It is the best choice for environmental protection, aquaculture, and drinking water ponds.

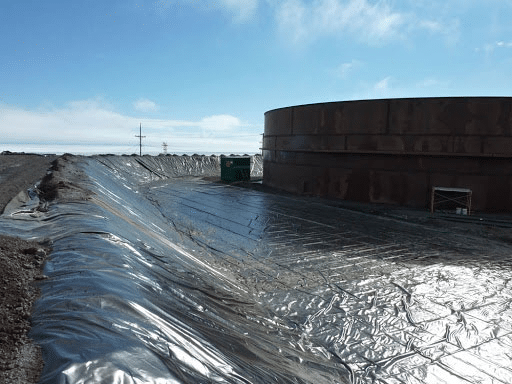

Applications of LLDPE Geomembrane

- Environmental protection, environmental sanitation (such as domestic waste landfills, sewage treatment plants, power plant regulating tanks, underground foundation waterproof and anti-seepage, factory roof moisture-proof industries, hospital solid waste, etc.)

- Water conservancy (such as seepage prevention, plugging, reinforcement of rivers, lakes, reservoirs and dams, seepage prevention of canals, vertical core walls, slope protection, etc.)

- Municipal engineering (highway, subway, underground engineering of buildings, planting roofs, anti-seepage of roof gardens, lining of sewage pipes, etc.)

- Gardens (roof gardens, artificial lakes, river courses, reservoirs, golf course pond bottom lining, slope protection, green lawns, waterproof and moisture-proof, etc.)

- Petrochemical (chemical plant, oil refinery, gas station’s oil storage tank anti-seepage, chemical reaction tank, lining of sedimentation tank, secondary lining, etc.)

- Mining industry (washing tank, heap leaching tank, ash dump, dissolution tank, sedimentation tank, storage yard, anti-seepage of the bottom lining of tailing, etc.)

- Traffic facilities (reinforcement of highway foundation, anti-seepage of culvert)

- Agriculture (reservoir, drinking water pond, impoundment pond, irrigation system anti-seepage, agricultural breeding such as pig farm septic tank)

- Aquaculture industry (aquaculture ponds, intensive, industrialized aquaculture ponds, fishponds, lining of shrimp ponds, sea cucumber ring slope protection, etc.)

- Salt industry (salt field crystallization pond, brine pond thatch cover, salt film, salt pond plastic thatch film)

Geofantex Geosynthetics have to make a series of guarantee for our products both plant processing and selling out to our customers. Selling to you is the first step, the service, and guarantee is our task. Geofantex Geosynthetics have an ISO Certificate to guarantee the raw material, the product processing, and the end product. From receiving your order to replacement and installation of the products, we have solved the problems in time if you need, whatever the quality and technics guideline or suggestions. Our company has been committed to supplying high-quality products with reasonable price and delivery in time.

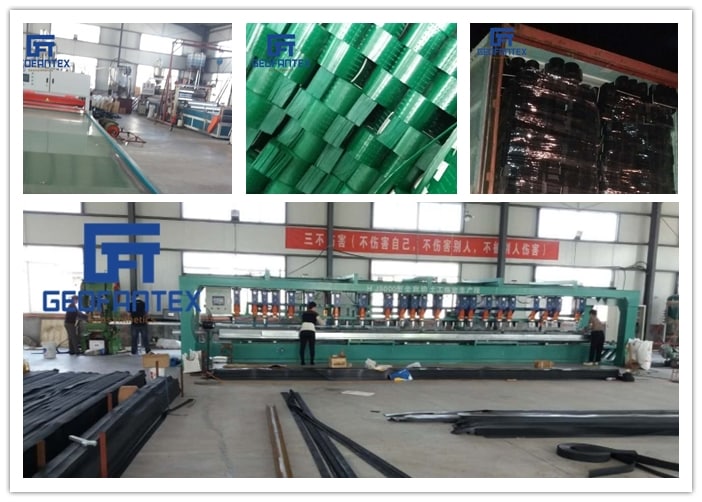

MANUFACTURING QUALITY ASSURANCE

GEOFANTEX has an on-site Manufacturing Quality Assurance Laboratory at the factory. GEOFANTEX maintains a high level of quality and up-to-the-minute results on finished products through a fully equipped, well-staffed, dedicated laboratory existing in each of the manufacturing facilities. Each facility follows the same guidelines for evaluating the quality of GEOFANTEX products and is capable of adapting to market-driven requirements.

A. Objective

The objective of the GEOFANTEX Quality Assurance program is to define the implementation of basic manufacturing quality assurance (MQA) procedures necessary to ensure the consistent production of quality products supplied to the geosynthetic market. Note that at this time, these procedures are limited to polyethylene geomembrane.

B. Scope

In order to achieve GEOFANTEX’s stated purpose, a rigorous set of minimum standards and an effective test program to assure compliance have been established. These procedures and requirements are frequently reviewed and adjusted to assure compliance with current market demands and/or predetermined project specifications. These procedures assure that raw materials and process parameters are controlled to provide products complying with GEOFANTEX’s pre-defined minimum characteristics.

PRODUCT IDENTIFICATION AND DOCUMENTATION

A. Roll Numbering

Each roll of geomembrane is assigned a unique roll number. The Quality Assurance Laboratory maintains records documenting the raw materials and resulting product quality information.

B. Approval Procedure

Results for each tested roll of the product are checked against both GEOFANTEX China standard and customer specifications for compliance. The Quality Assurance Laboratory approves those materials that meet these requirements for shipment.

C. Non-Conformance

Material that does not meet GEOFANTEX minimum standards is given a roll number but is rejected and not placed into inventory. The material is identified as scrap and will not be utilized. Material that meets GEOFANTEX minimum standards but does not meet a stricter customer specification is not allocated to that customer but is placed into inventory as GEOFANTEX standard material.

D. Documentation

Individual Quality Assurance Certificates are generated and supplied for each roll of geomembrane product to include all relevant quality assurance information about the material(s).

Geofantex Geosynthetics have a series of package and delivery service working procedures. Geofantex Geosynthetics have supplied thousands of containers to Latin America, North America, Southeast Asia, developed countries, and Africa within the past ten years. We provide the package of products with the rolls, pots, bags, sheets, or your requirement in orders. Our company has been committed to supplying high-quality products with reasonable price and delivery in time. Delivery one 40’HQ within 7 – 10 days. And we have an obligation in increasing loading quantity and make you save the freight costs maximally. We supply the products by plane, by sea and land carriage to any regions or any countries of the worldwide, even the door-to-door service.

| SEPARATION | REINFORCEMENT | FILTRATION | DRAINAGE | WATERPROOF | PREVENTION | POLLUTION PREVENTION | PROTECTION | CONSOLIDATE | |

| GEOTEXTILE | √ | √ | √ | √ | √ | √ | |||

| GEOMEMBRANE | √ | √ | √ | ||||||

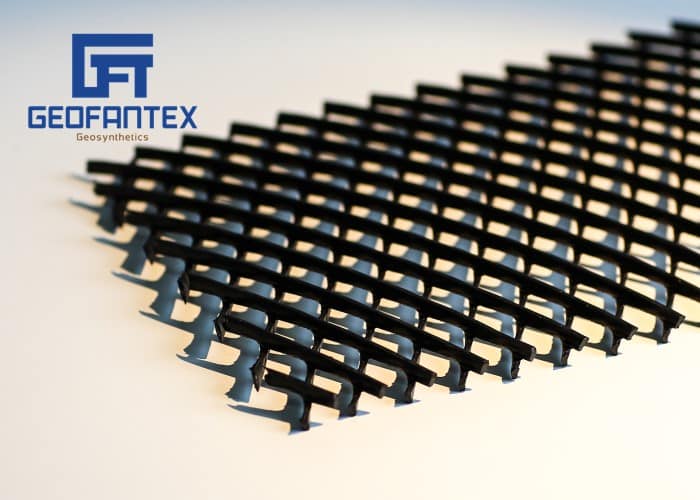

| GEOGRID | √ | √ | |||||||

| GEONET | √ | ||||||||

| GEOTUBE | √ | ||||||||

| GEOCELL | √ | √ | |||||||

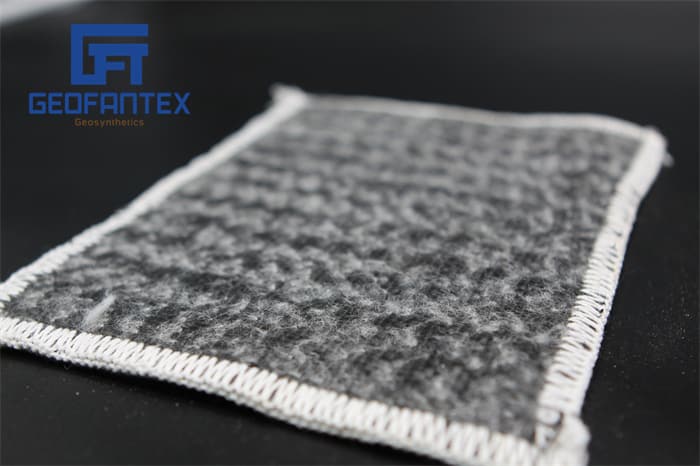

| GCL | √ | √ | |||||||

| GEOCOMPOSITE | √ | √ | √ | √ | √ | √ | √ | ||

| GEOCONCRETE BLANKET | √ | √ | √ | ||||||

| Drainage Board B | √ | √ | √ | √ | |||||

| Storage and Drainage Board | √ | √ | √ | √ | |||||

| Grass Paver | √ | √ | √ | √ | √ | √ | √ | ||

| Macmat | √ | √ | √ | √ | √ | √ | √ | ||

| GeoFanTex®GD 2L | √ | √ | √ | √ | √ | √ | |||

| GeoFanPipe® FP | √ | ||||||||

| GeoFanDrain® BC | √ | √ | √ | ||||||

| GeoFanPipe® DCP | √ | √ | |||||||

| GeoFanTRM® Geomantles | √ | √ | √ | √ | √ |

General Installation Guidelines

When working with a geomembrane liner, it’s crucial to comprehend the product’s strengths and the proper installation steps. This article outlines Geofantex’s installation guidelines, which draw from ASTM and the Geosynthetic Research Institute.

Step 1: Product selection and quality control

Always verify geomembrane liner quality with certifications, test results, and visual inspection. It must be new, defect-free, and in continuous sheets. Once approved, site preparation can begin.

Step 2: Subgrade Preparation in Construction

The base should be flat and compacted, with a compaction coefficient ≥ 0.95, local height difference ≤ 50mm, and no sharp objects.

Step 3: Geomembrane laying sequence

Extending from the bottom to the higher level, the slope is laid “from top to bottom”.

Step 4: Geomembrane Installation Quality Control Procedures

Because conditions affect weld quality, technicians should make a test weld before each session per ASTM D6392, then cut and check it to meet minimum strength requirements.

Step 5: Geomembrane Welding

Due to the significant impact of environmental conditions on weld quality, it’s advisable for welding technicians to conduct a test weld before each welding session. This test weld should adhere to ASTM D 6392 guidelines, using the same conditions, equipment, and materials as those employed during production. Subsequently, sections of the test weld should be cut and assessed against the minimum acceptable weld strength values.

Step 6: Testing Production Welds for Quality

Production welds should be tested upon completion using nondestructive methods before the geomembrane is covered. Any areas that fail these tests should be identified, repaired, and retested. Nondestructive testing methods can involve a vacuum box, air pressure, or spark testing equipment.

For additional assurance, it is recommended to perform destructive weld testing at intervals of 500 feet or as otherwise specified in GRI GM 14. If an independent weld test is necessary, it should adhere to ASTM 5820 or ASTM D6392 standards.

Geomembrane Installation Guide

If you would like further information about the installation guide, please

Certificate

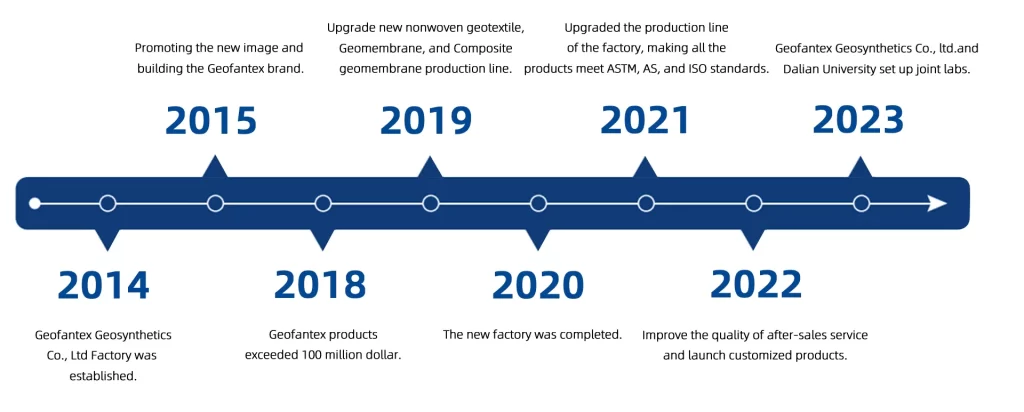

Development history of the company

Company Profile

Geofantex Geosynthetics Co., Ltd. is based in Dalian, a beautiful coastal city known for its excellent location and good transportation. Founded in 2014 with a registered capital of 5 million yuan, the company operates from an industrial park in Jinan, Shandong, covering over 50 acres. It features a modern office, advanced production equipment, and a skilled team in technical and management roles.

Geofantex has achieved ISO9001 and ISO14001 certifications and adheres to national standards to ensure product quality. Since its inception, the company has adopted advanced technologies and equipment, exporting products to regions like Australia, Canada, and Southeast Asia. Its export sales have reached significant figures, and customer feedback highlights our products’ stability, reliability, and cost-effectiveness.

The company leverages its innovative capabilities and market advantages, aiming to become a leading enterprise supported by national policies. Committed to “quality first” and “reputation first,” it emphasizes a people-oriented approach and values integrity, unity, and hard work. Geofantex seeks to collaborate with various engineering units to contribute to infrastructure development.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)