+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geotextile type, performance, engineering choice

Geotextiles are permeable materials that are made from polymers using various processes such as non-woven, woven, weaving, and wet-laid processes. They are widely used in construction fields such as civil engineering, water conservancy, water transportation, airport, and environmental protection.

Geotextiles play an important role in projects by providing functions such as infiltration, drainage, protection, separation, and crack prevention. They are versatile and can be used in a variety of applications to help improve the stability and durability of structures. Overall, geotextiles are an essential component of many construction projects and offer a range of benefits that make them a popular choice in the industry.

Form and classification

Geotextiles are divided into woven geotextiles (woven), nonwoven geotextiles (nonwoven), composite geotextiles, and wet-laid geotextiles according to different manufacturing methods.

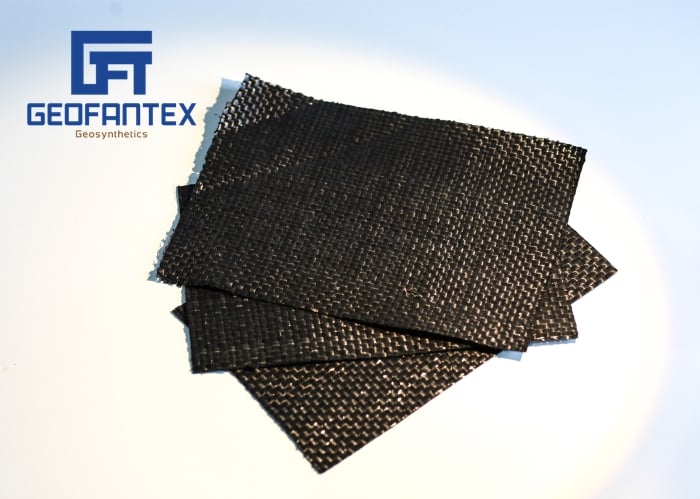

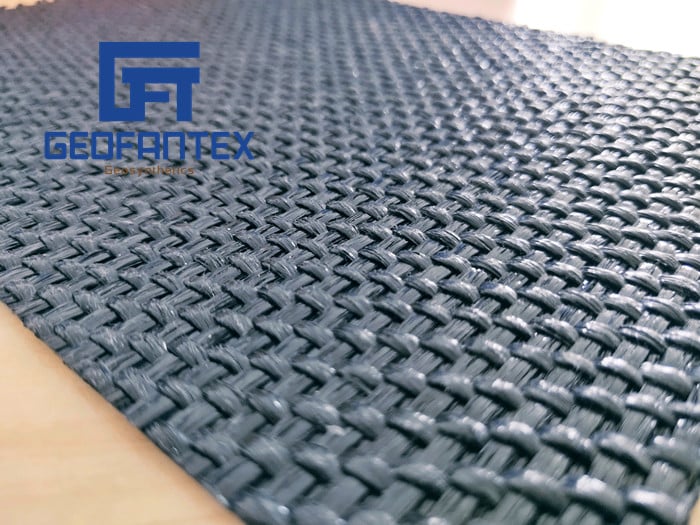

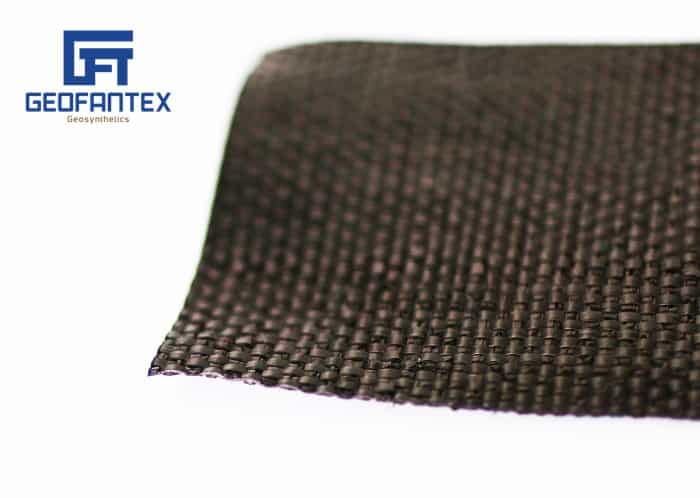

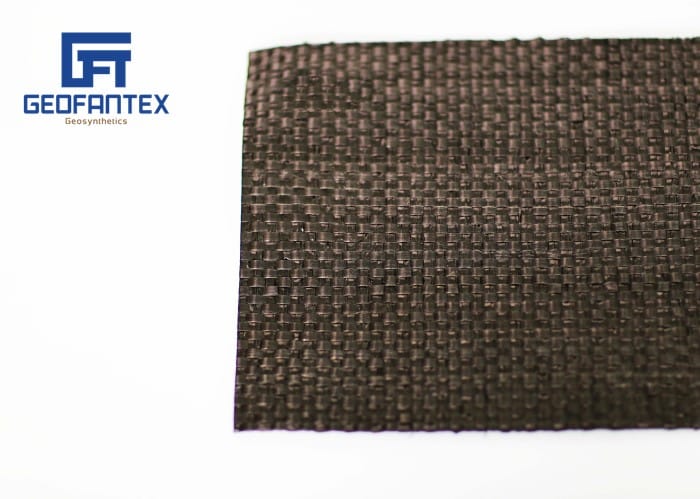

- The woven geotextile (woven) is composed of synthetic fiber filaments (polypropylene, polyester, nylon, vinylon, ethylene, etc.) or plastic flat yarn, plastic split film yarn arranged in a certain direction and woven geotextile;

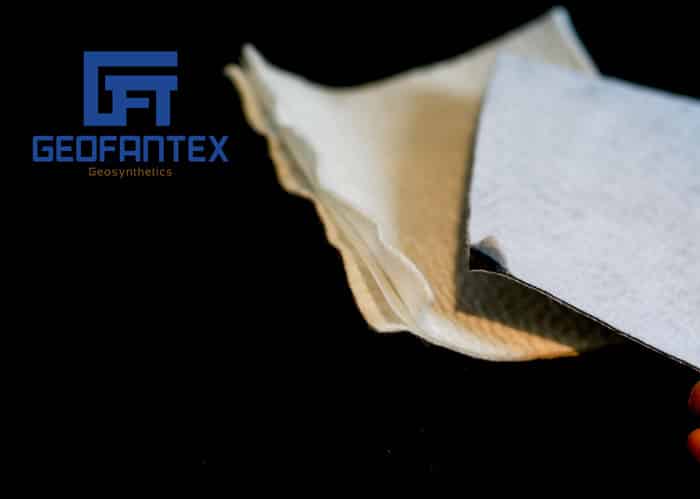

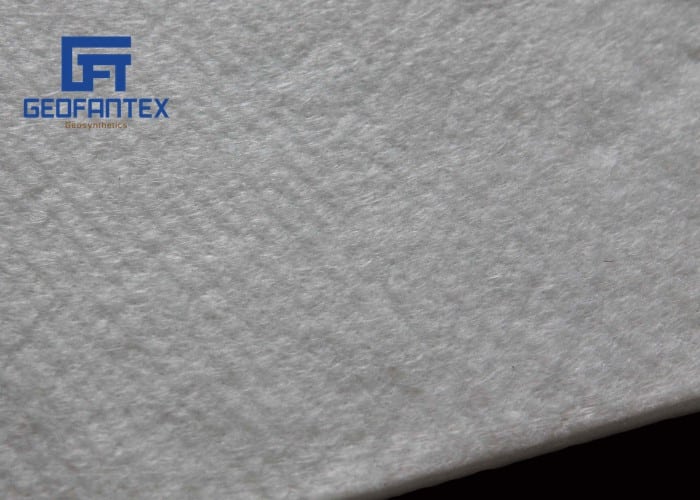

- Non-woven geotextile (non-woven) is a thin batt mat made of short fibers or filaments in random or directional arrangement, and is a fabric formed by mechanical bonding, thermal bonding or chemical bonding;

The wet-laid geotextile is made of chopped polyester fiber and glass fiber as raw materials, dispersed in water, and then manufactured through copying, dehydration, sizing, drying and other processes;

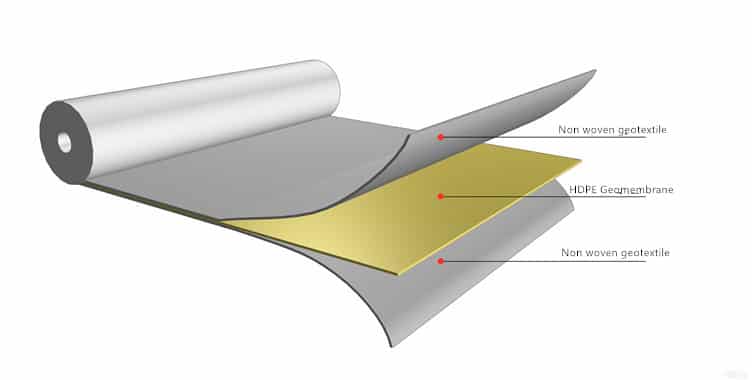

Composite geotextile: Filament woven geotextile or split film woven geotextile (woven geotextile) made of the polymer as raw material and staple fiber needle-punched nonwoven geotextile are composited by needle punching Geotextile. It has the functions of protection and reinforcement and is mainly used in engineering fields such as reinforcement of soft soil foundation and reinforcement of embankment base. According to the product structure, it is divided into two-layer composite and three-layer composite.

Geotextile is divided into

① polyester staple fiber needle punched nonwoven geotextile;

② polypropylene staple fiber needle punched nonwoven geotextile;

③ polyester filament spun bond needlepunched nonwoven geotextile;

④ polypropylene fiber Silk woven geotextile;

⑤ Polyester filament woven geotextile;

⑥ Basalt fiber woven geotextile;

⑦ Polypropylene split film woven geotextile;

⑧ Plastic flat woven geotextile;

⑨ Polyester glass fiber wet method Weaving geotextile.

- Composite geotextiles are divided according to material composition:①filament woven / staple fiber nonwoven composite geotextile (HWN / GFP/GFS);②split film woven / staple fiber nonwoven composite geotextile (WN / GFP/GFS);③Plastic flat braided / staple fiber nonwoven composite geotextile (WN/ GFS);④ staple fiber nonwoven / filament woven / short fiber nonwoven composite geotextile (GFS/ HWN / GFS);⑤ staple fiber nonwoven / Split film woven / staple fiber nonwoven composite geotextile (GFP / WN / GFP);⑥ staple fiber nonwoven / plastic woven flat weave / staple fiber nonwoven composite geotextile (GFS / WN/ GFP)

Geotextile can be divided into drainage filter geotextile, wrapped geotextile, separation geotextile, and reinforced geotextile according to different functions.

① Drainage and anti-filter geotextile: Geotextile keeps the liquid and gas from passing vertically while keeping the soil skeleton particles under the action of permeation force from being lost. Some geotextiles also serve as lateral drainage channels. Drainage reverse filter geotextile is mainly used for slope protection, wall or back filter layer, drainage blind ditch, soft foundation treatment, and other projects. Type permeable pipes, plastic drainage belts, bagged sand wells, or composite geomembrane outsourcing materials.

② Wrapped geotextile: Geotextile is used as loose soil, sand and stone wrap or as a carrier for concrete and mortar to form a block with a certain volume and shape for slope protection and erosion protection. The wrapped geotextile products mainly include geo bags, geomembrane bags and geotube bags. The geotextiles in the bagged sand sandwiched with a pebble filter layer and bagged sand wells also have the function of wrapping.

③ Separation geotextile: Geotextile is laid between different media to prevent mixing of adjacent different media. Separation geotextile is mainly used for separation between different size fillers of embankment or laying geotextile on the surface of soft soil to avoid blocking the upper drainage cushion.

④ Reinforced geotextile: Geotextile with a certain tensile strength is buried in the soil body, relying on its interaction with the soil interface to improve the strength and stability of the soil body and limit the displacement of the soil body. Reinforced geotextile is mainly used for reinforced soil structure, reinforced cushion in soft foundation treatment, or combined with geomembrane to form reinforced composite geomembrane.

- Polyester staple fiber needle-punched nonwoven geotextile: Geotextile is produced by using polyester staple fiber as raw material, using non-woven processes such as opening and scotching, carding, netting, and needle punching. Has the following performance:

① Good flexibility, corrosion resistance, and oxidation resistance.

② Has good permeability, filtration, and isolation performance.

- Polypropylene staple fiber needle punched nonwoven geotextile: It is made of high-strength low-elongation polypropylene staple fiber and is produced by a non-woven process. It has the following properties:

③ Separation, reinforcement, protection, filtration, drainage, buffering and other functions.

④ The physical and mechanical performance index is 2 to 3 times higher than that of polyester geotextile. The products with the same gram weight have low specific gravity, excellent acid and alkali resistance, good hot-melt adhesion, and strong wear resistance.

- Filament spunbond needle-punched nonwoven geotextile: using PET as raw material, the geotextile with three-dimensional pores is produced by melt-melting spinning, air drafting, pendulum wire laying and needle punching reinforcement process. Has the following performance:

① High mechanical index, good creep performance; strong corrosion resistance, excellent aging resistance, heat resistance, and excellent hydraulic performance.

- Plastic flat wire is woven geotextile: It is produced by drawing, cutting and weaving processes with polypropylene (PP) or polyethylene (PE) as the main raw material. Has the following performance:

① Lightweight, high strength, small elongation, good integrity, and convenient construction;

② It has the functions of reinforcement, separation, drainage filtration and fence.

5. Split film woven geotextile: It is made of polymer membrane-cutting yarn (yarn) and membrane-breaking yarn (yarn) by the weaving process. With the following properties:

① Lightweight, high strength, small elongation, good integrity, and convenient construction;

② It has the functions of protection, strengthening, isolation, filtration, and drainage.

- Basalt woven geotextile: A material made of basalt fiber roving by weaving process and chemically finished. The product has the following properties:

① It has the advantages of high strength, high modulus, lightweight, chemical resistance, good high and low-temperature stability, etc., and is widely used in civil engineering, water conservancy construction, aerospace and automotive fields.

- Composite geotextile: double-layer structure or multi-layer structure reinforced composite product composed of woven geotextile and non-woven geotextile. Has the following performance:

①High tensile strength, low elongation, uniform longitudinal, and lateral deformation, high tear strength, excellent wear resistance, high water permeability, and excellent filterability. It can improve the bearing capacity of soft ground and embankment base, reduce settlement and increase foundation stability.

② It has the functions of protection and reinforcement and is mainly used in engineering fields such as reinforcement of soft soil foundation and reinforcement of embankment base.

- Geotextile can be divided into drainage filter geotextile, wrapped geotextile, separation geotextile and reinforced geotextile according to different functions.

① Drainage and anti-filter geotextile: Geotextile keeps the liquid and gas from passing vertically while keeping the soil skeleton particles under the action of permeation force from being lost. Some geotextiles also serve as lateral drainage channels. Drainage reverse filter geotextile is mainly used for slope protection, wall or back filter layer, drainage blind ditch, soft foundation treatment and other projects. Type permeable pipes, plastic drainage belts, bagged sand wells or composite geomembrane outsourcing materials.

② Wrapped geotextile: Geotextile is used as loose soil, sand and stone wrap or as a carrier for concrete and mortar to form a block with a certain volume and shape for slope protection and erosion protection. The wrapped geotextile products mainly include geobags, geomembrane bags and geotube bags. The geotextiles in the bagged sand sandwiched with a pebble filter layer and bagged sand wells also have the function of wrapping.

③ Separation geotextile: Geotextile is laid between different media to prevent mixing of adjacent different media. Separation geotextile is mainly used for separation between different size fillers of embankment or laying geotextile on the surface of soft soil to avoid blocking the upper drainage cushion.

For more information please contact to Geofantex Geosynthetics Co., Ltd.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)